Website:

BRITMET TILEFORM LTD

Website:

BRITMET TILEFORM LTD

Catalog excerpts

PROFILE 49® PROFILE 49 PANEL Prole 49 panels roof pitches from 10° to 90°. Prole 49 lightweight roong tiles, to be supplied by Britmet Tileform Ltd. Each tile must be secured using four no. coloured, 2.6mm x 50mm galvanised xing nails, driven through the downturned nose of the tile into the face of the battens, (for 0.9mm Prole 49, a coloured Tex screw can be used – part no: ASF2 – 00E55). BATTENS Treated tiling battens of approved quality (e.g. tanalised), of suitable section, (see the Prole 49 estimating chart) to be laid at 365mm centres, (for 0.45mm thick) or 363mm centres (for 0.9mm thick), except the eaves batten (see eaves section), and secured to the rafters using galvanised nails. Joints in the battens should be staggered and meet half way across the top of the rafters, as standard code of practice. UNDERLAY Approved reinforced felt, BS747 (type 1F) to be laid over rafters, lapped and secured to the rafters with galvanised clout nails and carried well into gutters. All to comply with current regulations. ANGLE RIDGE FLASHING Two tile battens to be tted side by side on both sides of the ridge, using galvanised nails. An additional 50mm x 50mm batten to be secured on top of the rearmost of the two tile battens in a position to suit the tting of the Prole 49 angle ridge. If necessary, the top course of tiles to be cut and bent using a guillotine and bender (available from Britmet Tileform Ltd). The rear edge of the tile is to be turned up to form a 25mm to 38mm upstand against the top tile batten. Each tile must be secured using four nails driven through the downturn as previously described. EAVES VENTILATION Roof pitch above 15° The top of the fascia board should be xed 23mm below the top face of the eaves batten allowing for the Prole 49, 10mm eaves vent system. Roof pitch below 15° The top of the fascia board should be xed 25mm below the top face of the eaves batten allowing for the Prole 49, 25mm eaves vent system. Note: Where the insulation follows the roof slope, the Prole 49 ventilation tray should be installed between the rafters. VALLEY The valley should be formed from lead, moulded glass bre or similar approved lining, supported on valley boards. Tile battens should project over the valley to provide xing for the tiles. Prole 49 panels to be measured, cut and bent, using the guillotine and bender (available from Britmet Tileform Ltd), allowing sufcient downturn into the valley. BARGE BOARD COVER The timber barge board should project 25mm above the top of the tile battens. A 50mm x 50mm timber batten to run parallel to the fascia board. Prole 49 panels should be cut and bent up against the timber barge batten. The Prole 49 scribed barge board cover to be secured using 5 xing nails driven through the downturned edge into the barge board and ve nails to be driven vertically into the barge batten (the heads of the vertically xed nails to be sealed, using the Prole 49 nishing kit). SIDE-WALL FLASHING Prole 49 scribed side-wall ashing to be secured using xing nails, one driven vertically into each batten (these nail heads to be covered, using the Prole 49 nishing kit). The angle ridge ashing is to be tted over the top batten and nailed through the downturn of the ridge into the tile upstand and face of the batten, using ve nails on each side. Prole 49 cover ashing to be dressed over the vertical section of the side wall ashing and be dressed into the brickwork. ANGLE RIDGE (VENTILATED) ROOF PITCHES FROM 10° TO 35° Felt underlay to be cut back allowing a continuous 12.5mm air gap on either side of the centre line of the ridge. PROFILE 49 INLINE TILE AND SOIL VENT To provide additional ventilation, the Prole 49 inline tile vents are available providing an airow of 7,500mm2. If necessary, the top course of tiles to be cut and bent using a guillotine and bender (available from Britmet Tileform Ltd). Each tile to be secured using four xing nails driven through the downturn nose of the tile into the battens. A batten, not exceeding 50mm x 50mm to be tted on the universal vent piece, (supplied by Britmet Tileform Ltd) and secured through the tile into the battens on the underside, using 75mm galvanised nails. The ridge ashing to be tted over the batten and nailed through the downturn into the face of the batten using ve nails on each side. ANGLE HIP FLASHING A 38mm x 38mm hip batten to be nailed to the tile battens on each side of the hip rafter, using galvanised nails. Tiles to be cut and bent to form a 25mm – 35mm upstand against the hip battens, using a guillotine and bender (available from Britmet Tileform Ltd). The hip ashing is to be tted over the battens and nailed through the downturn, into the face of the battens using ve nails on each side. The tile underlay must be cut to allow the spigot of the tile vent to pass through. The Prole 49 panel vent is installed to provide full weather security. The tile vent is secured by overlapping an Prole 49 panel on either side and nailing through the nose of the tile, as previously described. Nails must not penetrate the vent tile. The Prole 49 inline vent tile can also be used as a weather protected exit point for soil pipes or extractor fan ducts by means of a exi hose and pipe adapter that connects the vent to 100mm stacks or duct work. PROFILE 49 GAS FLUE RIDGE TERMINAL Available to suit angle ridge. Type (R) adapter and extension piece supplied by others. Please note: This information is to be used as a guide only. It assumes that the structure of the existing building is in accordance with the building practice. At your request a custom specication can be written for your individual project. Please contact our technical department at the address shown below. EAVES The bottom course of tiles to be secured using four no. coloured, 2.6mm x 50mm galvanised xing nails driven vertically through the tile, as near to the high point of the tile prole as possible and into the fascia board, or through the eaves batten placed approximately 20mm behind the fascia board if the Prole 49 eaves ventilation system is used. These nail heads to be sealed using the Prole 49 nishing kit. The top of the fascia board or eaves vent, if used, to be in line with top of battens. Fit Lay Board or Tilting Fillet at the eaves if appropriate, to ensure any moisture on the underlay drains into gutter. PROFILE 49 Manufacturers of light weight roong systems Britmet Tileform Ltd, Spital Farm Ofces, Thorpe Mead, Banbury, Oxon. OX16 4RZ Tel: 01295 250998 Fax: 01295 271068 Email: sales@britmet.co.uk www.Britmet.co.uk BRITMET TILEFORM LIMITED

Open the catalog to page 1All BRITMET TILEFORM LTD catalogs and technical brochures

-

SLATE 600

1 Pages

-

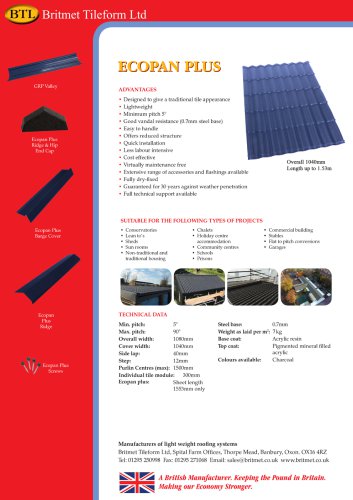

ECOPAN PLUS

1 Pages

-

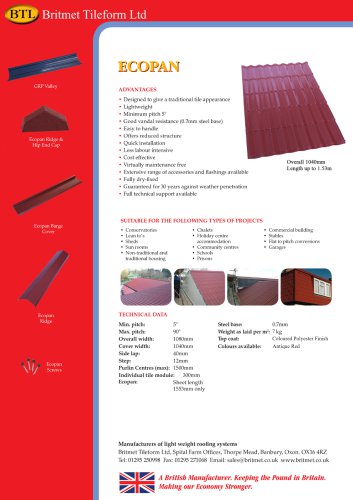

ECOPAN

1 Pages

-

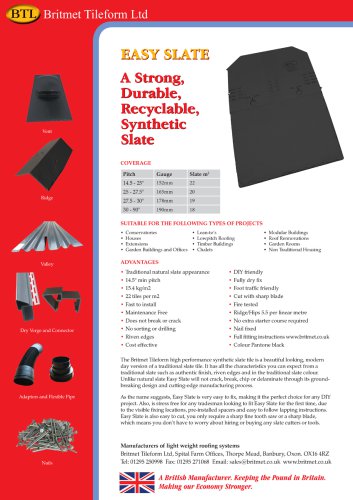

EASY SLATE

1 Pages

-

Vent 3 - Breathable Membrane

3 Pages

-

Pantile 2000

2 Pages

-

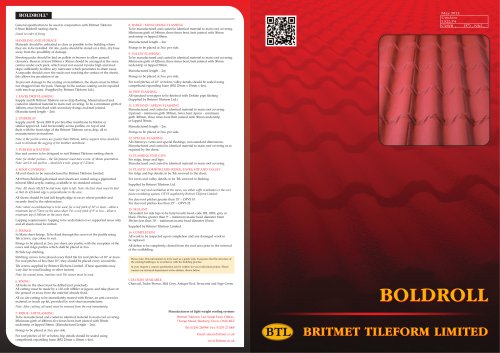

Boldroll

2 Pages

-

VILLATILE

2 Pages

-

ULTRATILE

2 Pages

-

Plaintile

2 Pages

-

Slate 2000

2 Pages

-

Renewable Energy - Solar PV

8 Pages

-

BritLight LED Lights

14 Pages

-

BritPaint

7 Pages

-

Colonade security pipe

13 Pages

-

Rainwater Products

11 Pages

-

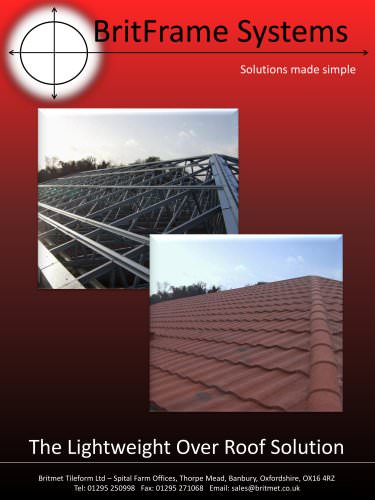

Britframe systems

12 Pages

-

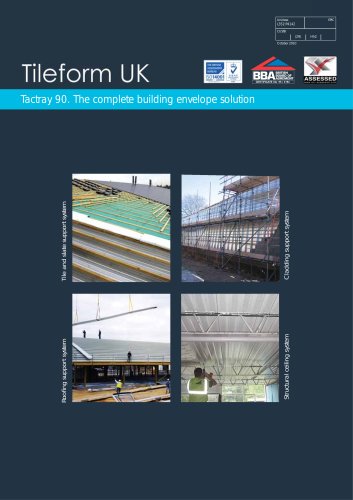

Tactray 90

40 Pages

-

Solar Panels

8 Pages

-

Export Catalogue

11 Pages