Website:

Bernardelli Group

Website:

Bernardelli Group

Catalog excerpts

PRE-DOSED FIBERED MORTAR FOR PLASTER AND MASONRY PRODUCT AND FIELDS OF APPLICATION MB5 is a pre-dosed fibered mortar in polyethylene bags containing in separate sections silico-calcareous aggregates, Portland cement, added minerals, polypropylene fibres and additives to improve the rheological characteristics of the product. The product complies with the European Standards EN 998-1 and EN 998-2 and comes within the parameters mentioned in Chapter 11 of the Ministerial Decree 14/01/2008 “New Technical Standards for Construction”. MB5 is a mortar suitable for the entrapment of load-bearing walls and not for making of internal and external plasters. The presence within of the formulation of selected aggregates, high quality cements, additives, make MB5 particularly workable and easy application, the polypropylene fibres instead allow to minimize the formation of macro cracks even in the case of plasters with thicknesses greater than 20 mm. Suitable for the entrapment of load-bearing walls MASONRY The clay bricks or concrete blocks must be clean, free of dust, grease and/or oil. With very high temperatures and dry weather it is advisable to moisten the bricks and blocks before laying the mortar. PLASTER The area of installation previously roughcast (at least 24-48 hours) should be free of dust, grease and/or oil. With very high temperatures and dry weather it is advisable to moisten the bricks and blocks before proceeding with the installation of the plaster. Suitable for internal and external plasters EDILQUATTRO BERNARDELLI GROUP A bag of MB5 is to be mixed with the addition of 3 litres of clean water by means of a mechanical mixer (cement mixer, cochlea kneader until obtaining a plastic and homogenous consistency and for not more than 3 minutes. MB5 can be mixed by hand with the aid of a shovel as long as the mixture is smooth and free of lumps. The application of MB5 must be performed by hand using a trowel, subsequently level with an aluminium straightedge and at the end float as with a wooden and/ or plastic trowel. Via del Canneto, 53 | 25010 Borgosatollo (BS) - ITALY | Tel +39 030 2702372 | Fax +39 030 2703192 info@bernardelligroup.com | www.bernardelligroup.com

Open the catalog to page 1

PRE-DOSED FIBERED MORTAR FOR PLASTER AND MASONRY TECHNICAL DATA DESCRIPTION TESTING METHOD AVERAGE VALUES NORMAL LIMITS (on an annual basis) Maximum size of the aggregate Consistency by means of concentrating table Working time Density of fresh mortar Density of hardened mortar Compressive strength after 28 days Dynamic elasticity modulus Adhesion to the surface - Type of Fracture Water absorption Thermal Conductivity [λ] (table value) PACKAGING Polyethylene bags of 25 kg (Product subject to natural shrinkage) MASONRY: Variable depending on the type of masonry Do not apply onto iced brick...

Open the catalog to page 2All Bernardelli Group catalogs and technical brochures

-

SMOOTHING-PLASTERS

2 Pages

-

ZERO IMPACT

5 Pages

-

SANDBLASTG

2 Pages

-

Decorstone e Water Save System

32 Pages

-

LAMIX|screw kneader

1 Pages

-

Depliant CLS (calestruzzi)

5 Pages

-

EDILQUARZ

2 Pages

-

Coloured mortars!

5 Pages

-

SILICAPRIMER

2 Pages

-

WPPASTE

2 Pages

-

CRUSHED WASHED SAND 0/5

1 Pages

-

PLASTER NATURAL SAND 0/4

1 Pages

-

CRUSHED ROCKS 2/6

1 Pages

-

NATURAL CASTING MIXTURE 0/12

1 Pages

-

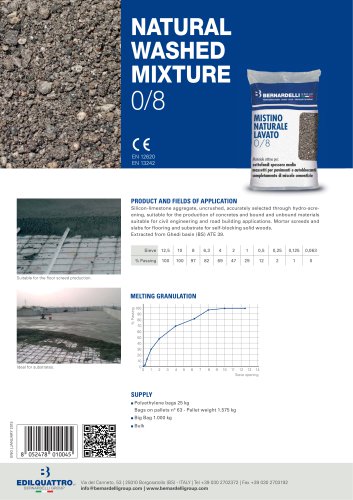

NATURAL WASHED MIXTURE 0/8

1 Pages

-

RASAGYPSFAST-SCAGLIOLA

2 Pages

-

RASAGYPS

2 Pages

-

RASACEMG

2 Pages

-

CLS40

2 Pages

-

CT20

2 Pages

-

MB5DRY

2 Pages

-

CT25DRY

2 Pages

-

ASPHALTALL

2 Pages

-

CLSDRENO

2 Pages

-

CLS30

2 Pages