Catalog excerpts

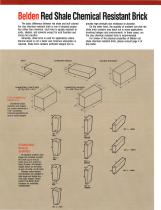

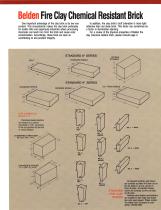

elden shale and fire clay chemical resistant brick offer engineers a wide range of utility in environments that involve aggressive corrosive conditions and elevated temperatures. These brick are currently in use in such industries as chemicals, steel, and metalworking, pharmaceuticals, pulp and paper, food and beverage, public utilities, aircraft, automotive and electronics. Typical applications in these industries are represented by process vessels, plating tanks, storage tanks, reaction vessels, fume ducts, scrubbers, bleach towers, waste treatment pits, rinse lines, and pickling tanks. Chemical resistant masonry construction is designed to protect containment tanks and vessels made of steel, concrete, ordinary masonry, fiber-reinforced polyesters and the like. Chemical resistant brick provides thermal, mechanical, and chemical protection for these kinds of structures. Belden chemical resistant brick is a particularly versatile construction material for sulfuric acid plants when installed as linings for carbon steel shells. These linings can be used regardless of the size of the vessels or equipment when prescribed construction techniques are followed. They can lower the temperature of the surface of the shell and eliminate erosion of the protective sulfate film. No other system of corrosion resistance can provide the same level of cost effective protection in wet areas where acid concentrations vary from 2% to 98% and at high temperatures, as the three component system using chemical resistant brick and mortar with a membrane backing. Historically, Belden corrosion resistant brick linings have won wide acceptance because of these features: • Usage flexibility without sensitivity to minor changes in chemical processes, and applicability for many different processes. • Cost savings: where alloys and special metals become uneconomical because of accelerated chemical attack at high temperatures, chemical resistant brick liners inside the vessel can lower temperatures and concentration levels, making it feasible to use less expensive alloys. • Repairability compared to the finite durability of alloys. • Insulation inside a vessel is less susceptible to damage than is external insulation. • Cooler operation reduces degree of external protection necessary for worker safety. Quality...from the ground up Belden chemical resistant brick, backed by more than 100 years of brick making experience, are manufactured of specially selected American shales and fire clays. These are fine-ground and specifically formulated for density and strength and fired at over 2000° F. This process results in brick that resists virtually all corrosive liquids and gasses, except for acid fluorides and strong hot caustics. BELDEN CHEMICAL RESISTANT BRICK IS IN SERVICE AT THESE COMPANIES BASF Corporation • Chrysler Corporation • Conoco • Delco Remy • E. I. DuPont De Nemours & Company • Gould Incorporated • GTE Products Corporation • Hoechst Celanese • Inland Steel • Johnson Controls • LTV Corporation • Mobay Corporation • Monsanto Enviro Chemical, Incorporated • Proctor & Gamble • Revereware Corporation • Rhone-Poulenc • Rohm & Haas • The Timken Company • Union Camp Corporation • U.S. Steel Corpora

Open the catalog to page 1

The basic difference between red shale and buff colored fire clay chemical resistant brick is one of physical properties rather than chemical. Each kind is equally resistant to acids, alkalies, and solvents except for acid fluorides and strong hot caustics. Generally, shale brick is used for applications where thermal shock is not a factor and minimum absorption is required. Shale brick contains sufficient integral iron to provide high strength and resistance to abrasion. On the other hand, the quantity of ambient iron that red shale brick contains may leach out in some...

Open the catalog to page 2

One important advantage of fire clay brick is its low iron content. This characteristic makes fire clay brick preferable for textile mills and paper/pulp industries where processing chemicals can leach iron from the brick and cause color contamination. Accordingly, these brick are seen as contributing to end product integrity. In addition, fire clay brick’s buff coloration is more light reflective than red shale brick. This factor can sometimes be a factor in illumination planning. For a review of the physical properties of Belden fire clay chemical reistant brick, please consult page 4....

Open the catalog to page 3

Belden Chemical Resistant Brick All Belden chemical resistant brick are manufactured to conform to or exceed ASTMC-279 and generally are available in the Type II designation. Minimum requirements regarding the ASTM-C279 specification are shown in the following table: Modulus of Rupture Water Absorption (Brick or Tile Flat- Maximum % by wise) min. psi (MPa) 2 hr Boiling Test Brick or Tile Brick or Tile Low Individual High Individual H2SO, Solubility Maximum % Weight Loss Average of 5 Brick or Tile Type I Type II Type II! Typical Physical Properites of Belden Shale and Fireclay...

Open the catalog to page 4All Belden Brick catalogs and technical brochures

-

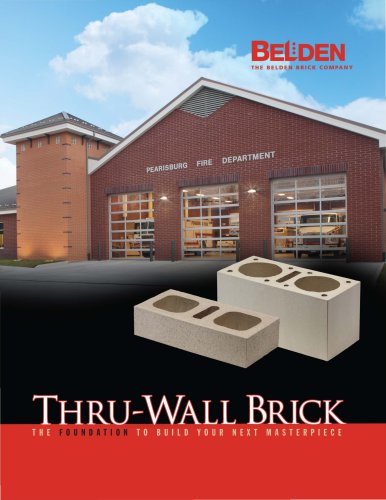

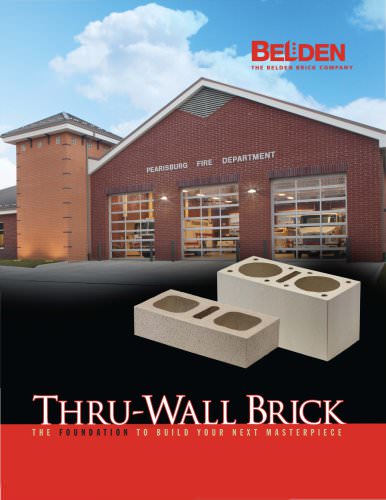

Thru-Wall Structural Brick

12 Pages

-

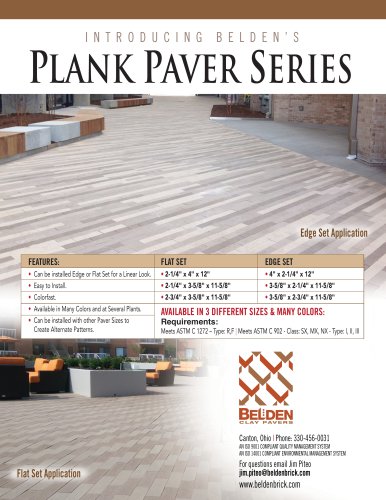

Plank Pavers Series

2 Pages

-

Permeable Clay Pavers

2 Pages

-

Concept Catalog

16 Pages

-

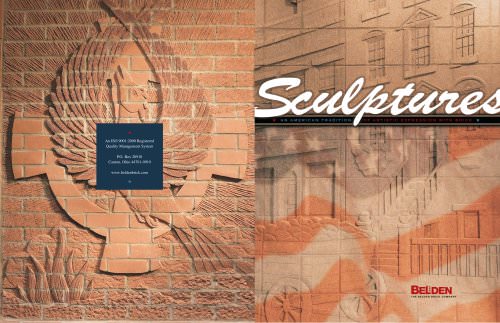

Brick Sculptures

4 Pages

-

Brick Chips

1 Pages

-

Belden Roman Brick

1 Pages

-

Belden Metallic Black

1 Pages

-

Dedication and Performance

14 Pages

-

Belden Brick History

8 Pages

-

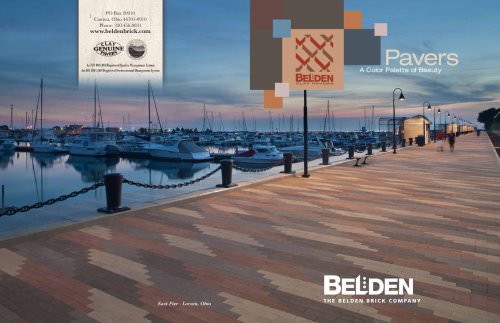

Brick Pavers

12 Pages

-

Thin Brick

24 Pages

-

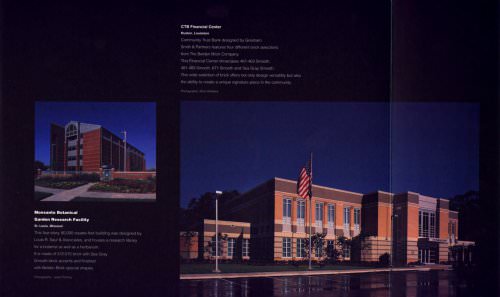

Landmarks in Brick

5 Pages

-

Sculpture

4 Pages

-

Thru-Wall Brick

12 Pages

-

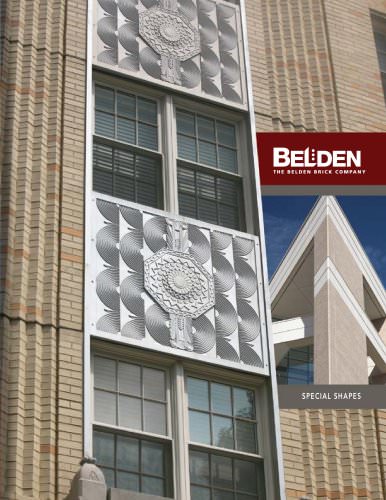

Special Shapes 2012

40 Pages

-

The Great American Home

39 Pages

-

AQUA-BRIC Permeable Pavers

8 Pages

Archived catalogs

-

Pavement catalogue

2 Pages

-

Bricks catalogue

8 Pages