Catalog excerpts

Think strategy

Open the catalog to page 1

Magnelis® Think strategy

Open the catalog to page 3

Outstanding corrosion performance Corrosion protection mechanism Edge protection with self-healing effect 15 Corrosion resistance, accelerated corrosion tests 17 Corrosion resistance, proven outdoors 19 Cost advantages over competing solutions 27 The environmentally responsible coating 29 Co-engineering Magnelis® solutions 33 Magnelis® outperforms pre-coated welded tubes 35 The durable coating for solar structures 41 Optimal protection for agricultural applications 45 Construction - Durability guaranteed 49 Infrastructure - Durable safety barriers, lighting poles,...

Open the catalog to page 5

• Excellent corrosion resistance: three times better than galvanised steel (based on outdoor tests) • Self-healing effect ensures excellent edge protection • Best and most cost-effective alternative to post-galvanised steels • Wide feasibility range • Excellent processing properties • Environmentally friendly

Open the catalog to page 6

What is Magnelis® ? Magnelis® is an exceptional metallic coating which provides a breakthrough in corrosion protection. Magnelis® is also the best choice for a wide variety of applications. Thanks to its unique composition, Magnelis® provides an unprecedented level of surface and cut-edge protection, even in the most hostile environments. Magnelis® is produced on a classic hot dip galvanising line, but the molten bath has a unique chemical composition including zinc, 3.5% aluminium, and 3% magnesium. Oil or E-passivation® Steel substrate Magnelis® has a naturally dark grey aspect. It is...

Open the catalog to page 7

Magnelis® provides outstanding corrosion resistance, even in harsh environments

Open the catalog to page 8

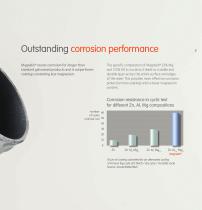

Outstanding corrosion performance Magnelis® resists corrosion for longer than standard galvanised products and it outperforms coatings containing less magnesium. The specific composition of Magnelis® (3% Mg and 3.5% Al) is crucial as it leads to a stable and durable layer across the entire surface and edges of the steel. This provides more effective corrosion protection than coatings with a lower magnesium content. Corrosion resistance in cyclic test for different Zn, Al, Mg compositions number 60 of cycles until red rust 50 40 30 20 10 0 10 µm of coating submitted for an alternated cycling...

Open the catalog to page 9

Magnelis® offers deformed surfaces extra protection

Open the catalog to page 10

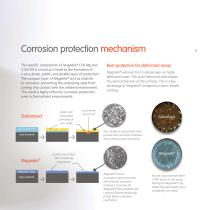

The specific composition of Magnelis® (3% Mg and 3.5% Al) is crucial as it leads to the formation of a very dense, stable, and durable layer of protection. The compact layer of Magnelis® acts as a barrier to corrosion, preventing the underlying steel from coming into contact with the ambient environment. The result is highly effective corrosion protection, even in the harshest environments. Best protection for deformed areas Magnelis® will even form a dense layer on highly deformed zones. This gives deformed steel shapes the same protection as flat surfaces. This is a key advantage of...

Open the catalog to page 11

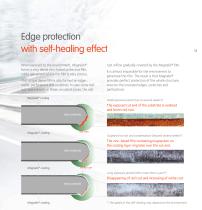

The self-healing effect of Magnelis® ensures the protection of uncoated edges, scratches and perforations The perforated zone on a safety barrier is protected by the self-healing effect of Magnelis®.

Open the catalog to page 12

Edge protection with self-healing effect When exposed to the environment, Magnelis® forms a very dense zinc-based protective film, unlike galvanised where the film is very porous. This unique dense film is also formed on edges, welds, perforations and scratches. In case some red rust was present on these uncoated zones, the red Magnelis® coating rust will be gradually covered by the Magnelis® film. It is almost impossible for the environment to penetrate this film. The result is that Magnelis® provides perfect protection of the whole structure, even on the uncoated edges, scratches and...

Open the catalog to page 13

The superior corrosion resistance of Magnelis® has been demonstrated in accelerated laboratory testing and proven through outdoor tests Magnelis® samples are tested in the laboratory.

Open the catalog to page 14

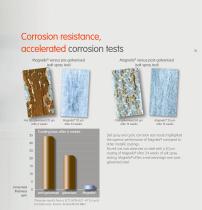

Corrosion resistance, accelerated corrosion tests Magnelis® versus pre-galvanised (salt spray test) Hot dip galvanised 20 µm after 6 weeks Magnelis® 20 µm after 34 weeks Coating loss after 6 weeks post-galvanised galvanised Magnelis® versus post-galvanised (salt spray test) Post-galvanised 85 µm after 12 weeks Magnelis® 20 µm after 12 weeks Salt spray and cyclic corrosion test results highlighted the superior performance of Magnelis® compared to other metallic coatings. No red rust was observed on steel with a 20 µm coating of Magnelis® after 34 weeks of salt spray testing. Magnelis® offers...

Open the catalog to page 15

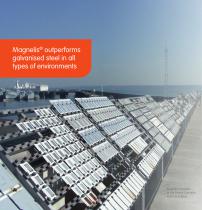

Magnelis® outperforms galvanised steel in all types of environments Magnelis® samples at the French Corrosion Institute in Brest.

Open the catalog to page 16

Corrosion resistance, proven outdoors More than thousand Magnelis® samples have been exposed to a variety of different environments around the world in outdoor tests. The samples included shapes such as flat sheets, tubes, and profiles, and a range of different dimensions. Magnelis® shows three times better protection than galvanised steel in all types of environments, and even more in very aggressive environments. Every test has confirmed the optimal protection provided by Magnelis® against long-term corrosion. Mean yearly consumed thickness* in different environments in microns/year...

Open the catalog to page 17

Post-galvanised versus Magnelis® Processing Surface finishing inspection Magnelis® Continuous and integrated process – in the case of Magnelis® – leading to cost reduction Visual inspection

Open the catalog to page 18

Advantages over post-galvanised steels • Freedom to optimise designs thanks to the ability of Magnelis® to protect deformed shapes • Lower weight of Magnelis® coating (depending on environment) to obtain the same level of corrosion resistance • Protects flat and deformed surfaces as well as cut edges • Shortens the logistics chain thanks to simpler fabrication processes. Cost effective compared to stainless steel and aluminium • Magnelis® provides the high level corrosion resistance of stainless and aluminium at a significantly lower cost. Reduces maintenance costs compared to...

Open the catalog to page 19All ArcelorMittal Europe – Flat Products catalogs and technical brochures

-

Granite®

23 Pages

-

Granite® Silky Shine

2 Pages

-

2019 Solano® Nature

2 Pages

-

Granite® Impression

8 Pages

-

Granite® Colour Palette

2 Pages

-

Granite® HFX Cool

2 Pages

-

GraniteEstetic

14 Pages

-

A90_Floor plates

4 Pages

-

Granite® - Estetic®

14 Pages

-

Indaten®

4 Pages

-

Granite® Quartz

2 Pages

-

Granite® Storm

2 Pages

-

Granite® HDX

4 Pages

-

Granite® Rain

2 Pages

-

Granite® Deep Mat

2 Pages