Website:

Arbloc srl

Website:

Arbloc srl

Catalog excerpts

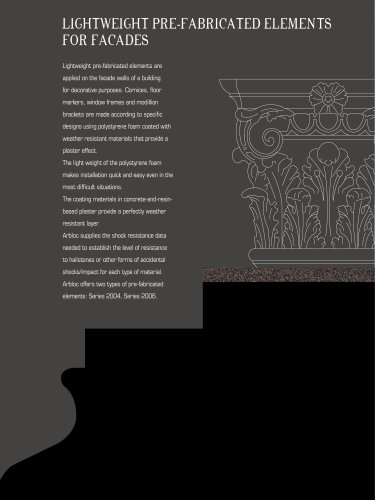

Lightweight pre-fabricated elements are applied on the facade walls of a building for decorative purposes. Cornices, floor markers, window frames and modillion brackets are made according to specific designs using polystyrene foam coated with weather resistant materials that provide a plaster effect. The light weight of the polystyrene foam makes installation quick and easy even in the most difficult situations. The coating materials in concrete-and-resin-based plaster provide a perfectly weather resistant layer. Arbloc supplies the shock resistance data needed to establish the level of resistance to hailstones or other forms of accidental shocks/impact for each type of material. Arbloc offers two types of pre-fabricated elements: Series 2004, Series 2006.

Open the catalog to page 1

Note: some minute cracks may appear during the transport or after the installation, which however do not reduce the quality of the product over time and can effectively be filled and sealed with an elastomeric coating. Polystyrene foam core. Concrete, resine additives and inert selected. Series 2004 lightweight pre-fabricated elements are made by hand in the same way as in the past using a time-tested technique, This time-tested technique is now adapted and used on a modern material such as polystyrene foam. The coating is composed of cement, resin additives, and inert selected, and it's...

Open the catalog to page 3

Note: some minute cracks may appear after the installation, which however do not reduce the quality of the product over time and can effectively be filled and sealed with an elastomeric coating. FEATURES Polystyrene foam core. Polyurethane resin and marble granules/dust based finish. Series 2006 lightweight pre-fabricated elements are made with modern products and techniques. They have a core made of polystyrene foam, cut according to design and a coating in compact, stiff polyurethane resin with added marble granules. This product can satisfy the widest range of demands in terms of form...

Open the catalog to page 4

USERS MUST KNOW THE FEATURES OF A LIGHTWEIGHT PRE-FABRICATED ELEMENT IN ORDER TO INSTALL IT PROPERLY. THERMAL EXPANSION The thermal expansion of polystyrene foam is higher than stone-like materials usually used in construction. The X coefficient ranges from 5 ■ 10-5 - 7 ■ 10-5. Compared to concrete (X = 1.2 ■ 10-5), polystyrene's thermal expansion is 4 to 6 times higher. Variations can reach 1.5 mm per 1 m in length with a 30°C thermal increase. Hence each installation must be evaluated carefully, especially in terms of support, glues, and mechanical anchors, besides the finish of the...

Open the catalog to page 5

SERIES 2004 LIGHTWEIGHT PRE-FABRICATED ELEMENT

Open the catalog to page 6

installing a lightweight pre-fabricated cornice INTRODUCTION Installing a lightweight pre-fabricated element requires proper fixing. Otherwise thermal expansions among different materials may, over time, lead to cracks on the joins, detachments from the wall or crevices on the surface. The thermal expansion of polystyrene foam is higher than stone-like materials. Not bearing this aspect in mind might jeopardize the final result. Each installation must be evaluated carefully especially in terms of support, glues, and mechanical anchors. Big cornices - such as under-roof and under-gutter ones...

Open the catalog to page 7

MOUNTING WITH SUPPORTING TIMBERING The pre-fabricated element is fixed on the timbering and laid against polystyrene elements that avoid overturning. The prefabricated elements are custom-made and delivered with already cut and joined corners. If requested, we can provide a drawing that shows how to place the elements. EXECUTION PHASES FINISHING In the last phase of construction the polyurethanic foam is injected in the joins to glued them together. We suggest to do this in winter months, when lower temperatures reduce reduction of the polystyrene. The join is concealed with a fiberglass...

Open the catalog to page 8

installation of f loor markers Example A finished plaster To install floor markers, apply the cement glue on the entire surface of the pre-fabricated element and use anchors to press the lightweight pre-fabricated element against the wall during the first few hours before the adhesive holds firmly. When the floor marker is glued directly on the plaster (example A) check this has good consistency. An insufficient plaster can lead to detachment following thermal expansion. We recommend you always use a special adhesive for walls. When external insulation is applied we recommend you glue the...

Open the catalog to page 9

window frames

Open the catalog to page 12

window frames

Open the catalog to page 13

window frames

Open the catalog to page 14

window frames

Open the catalog to page 15

window sills

Open the catalog to page 16

window sills

Open the catalog to page 17

f loor markers and bases

Open the catalog to page 18

photo gallery

Open the catalog to page 25

photo gallery

Open the catalog to page 26

photo gallery

Open the catalog to page 27

photo gallery

Open the catalog to page 28

photo gallery

Open the catalog to page 29

photo gallery

Open the catalog to page 30All Arbloc srl catalogs and technical brochures

-

arbloc

149 Pages

-

Arbloc presentation

12 Pages

-

Company Overview

12 Pages