Catalog excerpts

A cleaner, safer, faster alternative to Pour Strips Wfkable Dowels For Temporary Movement Joints UILDING PRODUCTS

Open the catalog to page 1

Ancon Lockable Dowels Contents Advantages and Applications Range of Lockable Dowels Performance Data Edge Distance and Spacings Reinforcement Details Other Ancon Products Ancon Lockable Dowel US Patent No. 8209933 Singapore Patent No. 159760 South Africa Patent No. 2010/01651 New Zealand Patent No. 583887 Other patents pending Lockable Dowels Lockable Dowels have been designed by Ancon for use at temporary movement joints, most commonly found in post-tensioned concrete frames. These dowels allow initial shrinkage of the concrete to take place and are then locked in position with a...

Open the catalog to page 2

Applications In most cases, Ancon Lockable Dowels can be used to replace pour strips at temporary movement joints in post-tensioned concrete frames. Standard Ancon systems are available for use at slab joints and retaining / core walls. By using these dowels we have saved at least four weeks per storey. This construction method is just more efficient. Wet trades finish sooner on site and the anticipated movement at the joints was achieved without any issues. PJ Carey chose the lockable dowel system because it offered time and cost savings, accelerating an already fast build programme....

Open the catalog to page 3

Ancon Lockable Dowel Brochure UK 2013:- Ancon Lockable Dowels Range of Lockable Dowels A Lockable Dowel allows initial shrinkage of the concrete to take place and then, after a pre-determined time period (generally 3-4 weeks), is locked in position with a mechanical plate and a controlled amount of epoxy resin. The range comprises three products; ESDQ-L20, HLDQ-L30 and ESDQ-L20W. Locking Plate (notches indicate minimum resin depth) Slab-to-Slab Lockable Dowels ESDQ-L20 The dowel component is manufactured from 30mm diameter stainless steel; one end features two fixed overlapping anchor discs...

Open the catalog to page 4

Locking Plate (notches indicate minimum resin depth) Slab-to-Wall Lockable Dowel ESDQ-L20W The dowel component is manufactured from 30mm diameter stainless steel, but is shorter than the ESDQ-L20 dowel. One end of the dowel is designed to fix into the stainless steel Ancon SKS24 Threaded Anchor cast into the face of the concrete and the other end features a series of grooves to accept the Locking Plate. The sleeve component is the same as used in the ESDQ-L20. See pages 6-9 for full technical details. Two-part Epoxy Resin Sleeve Component featuring void former supplied with label on nailing...

Open the catalog to page 5

Ancon Lockable Dowel Brochure UK 2013:- Ancon Lockable Dowels Performance Data Movement Vertical load transfer between slabs Vertical load transfer between slabs Load transfer between slabs Locked ESDQ-L20 Lockable Dowels (slab-to-slab) Slab Thickness (mm) Tension along line of dowel (kN) Vertical Design Resistance (kN) for Various Design Joint Widths (mm) in C30/37 Concrete 15 20 25 30 12.0 25.0 40.0 53.6 62.2 66.6 ESDQ-L20W Lockable Dowels (slab-to-wall) Slab Thickness (mm) Tension along line of dowel (kN) Vertical Design Resistance (kN) for Various Design Joint Widths (mm) in C30/37...

Open the catalog to page 6

Edge Distance and Spacings For connectors working at or near their maximum capacity, the minimum spacing should be 1.5 times the slab thickness. Where the design load of the connector could be used in a thinner slab, a spacing of 1.5 times the thinner slab thickness can be used. The minimum end distance is always 0.5 times the spacing. ESDQ-L20 Minimum Edge Distance and Spacings HLDQ-L30 Minimum Edge Distance and Spacings ESDQ-L20W Minimum Edge Distance and Spacings. h = depth of adjoining slab Maximum width of joint = 20mm (based on slabs 260mm and above) As an ESDQ-L20 can be used in a...

Open the catalog to page 7

Ancon Lockable Dowels Reinforcement Details Local reinforcement is required around each Ancon Lockable Dowel to guarantee that the forces are transferred between the connectors and the concrete. Correct detailing in accordance with appropriate design codes and the recommendations provided here will ensure the dowels attain their full capacity. The tables show the main reinforcement required, together with details of reinforcement above and below the connectors. Although only the sleeve components are illustrated, the same reinforcement is required around the dowel component. Options for...

Open the catalog to page 8

Dowel Component Dowel Component lateral movement- Dowel Component Sleeve Component lateral movement

Open the catalog to page 9

Ancon Lockable Dowels Installation Slab-to-Slab Although installation is shown for the ESDQ-L20, the procedure is the same for the HLDQ-L30. 1 Nail the sleeve to the formwork either central in the slab or for slab depths over 300mm so the top of the void former is level with the top of the slab. Do not remove the label over the nailing plate as this prevents ingress of concrete into the sleeve. Fix the local reinforcement, as specified on engineer’s drawings. 4 Pour the concrete, and when of sufficient strength, strike the formwork. Puncture the label to reveal the cylindrical sleeve only...

Open the catalog to page 10

Project References Other Ancon Products DSD/Q Shear Load Connectors Ancon DSD and DSDQ double-dowel connectors are used to transfer shear across movement joints in suspended concrete slabs. They are more effective at transferring load and allowing movement than standard single dowels and can be used to eliminate double columns at structural movement joints in buildings. The Q version features a rectangular box section to allow lateral and some rotational movement. 200 Lockable dowels were installed on the James Hehir Building (University Campus Suffolk phase 2) in Ipswich, UK ‘Highly...

Open the catalog to page 11

Masonry Support Systems Lintels Masonry Reinforcement Windposts and Parapet Posts Wall Ties and Restraint Fixings Channel and Bolt Fixings Tension and Compression Systems Insulated Balcony Connectors Shear Load Connectors Punching Shear Reinforcement Reinforcing Bar Couplers Reinforcement Continuity Systems Stainless Steel Fabrications Flooring and Formed Sections Refractory Fixings Ancon Building Products President Way, President Park Sheffield S4 7UR United Kingdom Tel: +44 (0) 114 275 5224 Fax: +44 (0) 114 276 8543 Email: info@ancon.co.uk Visit: www.ancon.co.uk Follow on Twitter:...

Open the catalog to page 12All Ancon Building Products catalogs and technical brochures

-

Eazistrip

16 Pages

-

Tapered Thread Couplers

12 Pages

-

MBT MechanicallyBolted Couplers

10 Pages

-

Staifix HRT4 Wall Tie

1 Pages

-

2019 Staifix Wire Balloons

1 Pages

-

Stainless steel wall ties

1 Pages

-

EC2-Compliant Design Method

12 Pages

-

Reinforcing Bar Couplers

28 Pages

-

Tension and Compression Systems

16 Pages

-

Restraint System

4 Pages

-

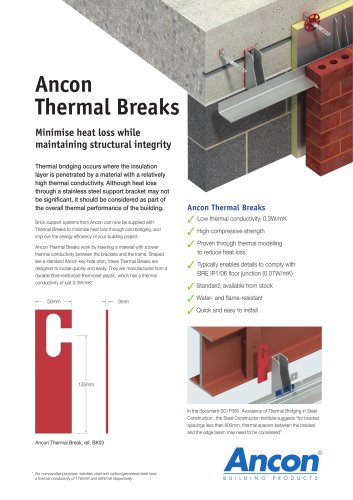

Ancon Thermal Breaks

2 Pages

-

Gauge Tape

2 Pages

-

Non-Drill Wall Ties

6 Pages

-

Refractory Fixings

8 Pages

-

Staifix Wall Ties

2 Pages

-

Special Fabrications

12 Pages

-

Punching Shear Reinforcement

12 Pages

-

Starter Bar Systems

8 Pages

-

KSN Anchors

24 Pages

-

DSD/ESD Shear Load Connectors

20 Pages

-

Masonry Reinforcement

16 Pages

-

Tension and Compression Systems

16 Pages

-

Corner Guards

2 Pages

-

Hidden Strength

7 Pages

-

Stainless Steel in Construction

12 Pages

-

12 Page Product Guide

12 Pages

-

Wall Ties and Restraint Fixings

32 Pages

Archived catalogs

-

2016 Staifix Wire Balloons

1 Pages

-

Channel and Bolt Fixings

20 Pages

-

Windposts and Parapet Posts

8 Pages