Website:

American Piledriving Equipment Inc.

Website:

American Piledriving Equipment Inc.

Catalog excerpts

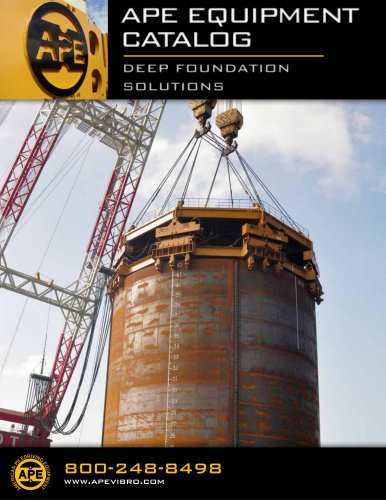

APE EQUIPMENT CATALOG DEEP FOUNDATION SOLUTIONS

Open the catalog to page 1

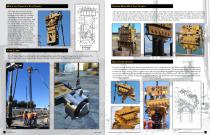

Company Profile APE: We’re on the job American Piledriving Equipment Inc. has a unique way of doing business in the deep foundation construction industry. We devise, manufacture, load, and ship our own products. We don’t rely on distributors; we rent and sell directly to the contractor. We get our equipment to the job site and we set it up. We get our people in the field where they can help, teach and learn with the customers. Wood and Concrete Pile Clamps Centerline Clamp Caisson Beam With Two Clamps Quad Clamp System Hydraulic Impact Hammer Technology Direct Fluid To Torque Top Drive...

Open the catalog to page 2

Wood and Concrete Pile Clamps Caisson Beam With Two Clamps APE single-arm wood and concrete clamps incorporate patented features not found on any other type of clamps. These features provide the contractor with an edge over his competition. APE developed the first wood and concrete pile clamps with a pivoting jaw and an open window that allows a pile crew to actually see the clamping jaws. APE clamps feature a topside anvil so piles can be driven without impacting the mounting bolts. The T-Bar mounting design eliminates the need to ever crawl inside the clamp jaws for attachment...

Open the catalog to page 3

Hydraulic Impact Hammer Technology In response to the great demand for low headroom hammers, needed on both seismic retrofit jobs and overhead obstructions such as power lines and indoor foundations, APE developed its own line of low headroom hydraulic impact hammers. APE hydraulic impact hammers feature a patented (US-006557649) double walled lifting cylinder that raises the ram from the bottom. Round concrete pile follower. Box lead fixed pile gate. Floating pile gate on front riding leader. This technology greatly reduces the overall height, making the APE hydraulic hammer the shortest...

Open the catalog to page 4

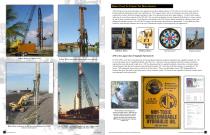

Direct Fluid To Torque Top Drive Augers APE introduced cam-track technology to the augured-cast-in-place piling industry in 1993 when it converted a state-of-the-art Poclain hydraulic radial piston motor into a drilling tool. The compact motor, with its revolutionary cam-track roller pistons, needed only a hollow shaft and stronger bearings in order to revolutionize the top drive auger industry. No drill on the market today has the crowd force capacity of the APE drill. The cam-track technology converts hydraulic fluid directly to torque without the aid of gears or planetary drives. No bull...

Open the catalog to page 5

Patents Define Our Knowledge Patent 5,263,544 - Shock absorbing apparatus The two-stage rubber suppressor takes the vibration out during start and stop while increasing line pull ability. It also provides crane operator visual indicator that measures the line pull. Patent 5,355,964 - Pile driving and/ or pile pulling vibratory assembly with counterweights Eccentric cast in one piece with helical gear to eliminate bolts and pins that fail inside vibratory pile driver/extractors. Eccentric is filled with heavy metal lead or tungsten, thus providing more eccentric moment with less parts....

Open the catalog to page 6

Patent 5,794,716 - Vibratory systems for driving elongated members into the earth in inaccessible areas A template that is mounted to a hydraulic power unit that includes hydraulic leveling and pile positioning. System is commonly used in wet land areas where access is only possible via helicopter. Unit operates on vegetable hydraulic oil to prevent poisoning of wild life and vegetation should a hydraulic leak occur. Patent 6,039,508 - Wick drain installation device A system to drive wick drain mandrels into the soil using a combination of static force and dynamic force. Consists of a...

Open the catalog to page 7

Pile Driving School For the past 15 years APE, in conjunction with local unions throughout the United States and Canada, has been hosting a pile driving school free of charge for pile bucks around the country. The success of the school stems from the massive amount of knowledge that is presented by the APE staff through hands on experience at our locations or in the field. At APE’s facilities, students see actual hammer manufacturing in process, including welding and machining of vibratory pile driver/extractors, drills, pile leads and other related equipment. Students participate with APE...

Open the catalog to page 8

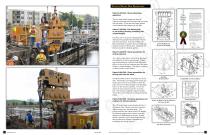

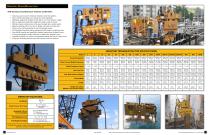

Vibratory Driver/Extractors • One-piece gear/eccentric eliminates fasteners inside the gearbox. • Heavy-Metal technology raises energy for more amplitude. • Multistage suppressor doubles the line pull at 1/3 of the hammer weight. • Bolt-on suppressors adjust the height and weight to job site needs. • Helical-cut gears add precision to the gear strength and eccentric speed. • Spherical bearings allow the vibro to handle side loads on batter piles. • Vibro can be used horizontally for stuck horizontal casing. • Field-designed assembly makes maintaining APE products simple and easy. •...

Open the catalog to page 9

APE Variable Moment Technology lets our driver/extractors shine in jobs with vibration sensitive requirements. APE Variable Moment Technology is teamed with all the special features available with the full line of APE Vibratory Driver/Extractors. • Gun drilled top plate and manifolds eliminate unnecessary hydraulic hoses. • O-ring sealed gearbox makes transition to underwater operations easy. • Vegetable hydraulic oil reduces environmental impact and fines if a spill occurs. • Long term warranty protection provides security on the investment.

Open the catalog to page 10

Tandem Vibratory Driver/Extractors Low Headroom Vibratory Driver/Extractors Low Headroom Driver/Extractors APE Low headroom vibratory pile driver/extractors are designed to allow the contractor to drive full-length piles under bridges or inside buildings. This system was created to solve low headroom issues for seismic retrofit applications. Specifications for the dimensions and max line pull are custom for the job the vibratory hammer will be used on. The suppressor setup will be modified by APE to work with specified height restrictions on the job site. Please consult an APE...

Open the catalog to page 11All American Piledriving Equipment Inc. catalogs and technical brochures

-

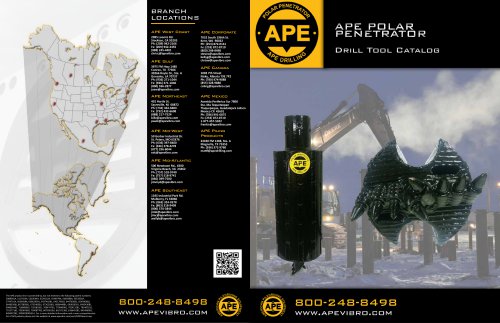

APE Polar Penetrator

2 Pages

-

Diesel Hammers

28 Pages

-

Air Hammers

39 Pages

-

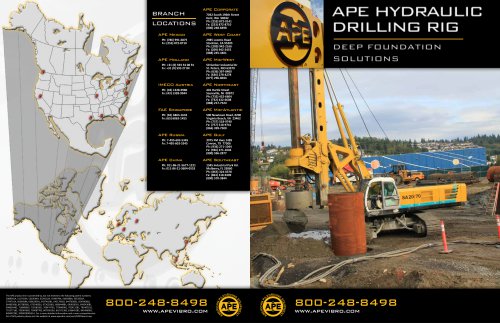

Drill_rigs

2 Pages

-

APE MODEL 85

2 Pages

-

APE HD™ DRIVERS

2 Pages

-

APE HD™ HELICAL

2 Pages

-

APE Field Catalog

31 Pages