Website:

American Piledriving Equipment Inc.

Website:

American Piledriving Equipment Inc.

Catalog excerpts

First Steam hammer made in the US in 1845 Drawing of Nasmyth’s original Steam Piledriver Circa 1845

Open the catalog to page 2

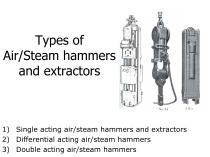

Types of Air/Steam hammers and extractors 1) Single acting air/steam hammers and extractors 2) Differential acting air/steam hammers 3) Double acting air/steam hammers

Open the catalog to page 3

Air/Steam single acting hammers: Vulcan Lifting Sheave Cylinder Steam chest Slide bar Trip (timing device) Ram (lump) Columns Ram point Wedges (Cyl, ram ,base)

Open the catalog to page 4

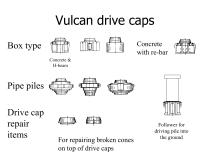

Vulcan drive caps Concrete with re-bar Box type Concrete & H-beam Pipe piles Drive cap repair items For repairing broken cones on top of drive caps Follower for driving pile into the ground

Open the catalog to page 5

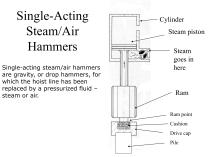

Single-Acting Steam/Air Hammers Single-acting steam/air hammers are gravity, or drop hammers, for which the hoist line has been replaced by a pressurized fluid – steam or air. Cylinder Steam piston Steam goes in here Ram Ram point Cushion Drive cap Pile

Open the catalog to page 6

In single-acting hammers, the motive fluid (air or steam) is working on the upstroke only. The ram falls by gravity on the down stroke. On upstroke, the motive fluid flows under the piston through an open valve. The piston is forced up, lifting the ram to which it is rigidly attached. At the top of the stroke, a valve rotates, blocking the inlet motive fluid path and opening a fluid path to the exhaust port of the hammer. The motive fluid rushes through the exhaust port and the ram falls by gravity. This operation is repeated for each hammer stroke.

Open the catalog to page 7

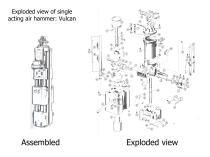

Exploded view of single acting air hammer: Vulcan Exploded view

Open the catalog to page 8

Single acting air/steam: Vulcan Adding mass to the ram to increase foot pounds of energy

Open the catalog to page 9

Keeping Ram Keys Tight Single acting air/steam: Vulcan Maintenance When some hammers get enough mileage on them to warrant retirement and under certain driving conditions, the contractor may have trouble keeping the ram keys tight. Usually under these circumstances, the contractor will weld the keys to the ram and worry about the consequences later. The drawing above shows a better way of keeping the keys tight and allows for quick and easy retightening during the job.

Open the catalog to page 10

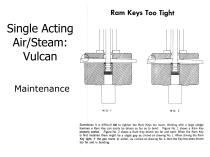

Sometimes it is difficult not to tighten the Ram Keys too much. Working with a large sledge hammer a Ram Key can easily be driven so far as to bend. Figure No. 1 shows a Ram Key properly seated. Figure No. 2 shows a Ram Key driven too far and bent. When the Ram Key is first installed there might be a slight gap as circled on drawing No. 1. When driving the Ram Key tight, if the gap starts to widen, as circled on drawing No. 2, then the Key has been driven too far and is bending.

Open the catalog to page 11

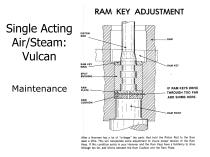

Single Acting Air/Steam: Vulcan Maintenance After a Hammer has a lot of "mileage” the parts that hold the Piston Rod to the Ram wear a little. This will necessitate some adjustment to insure proper tension of the Ram Keys. If this condition exists in your Hammer and the Ram Keys have a tendency to drive through too far, add Shims between the Ram Cushion and the Ram Plate.

Open the catalog to page 12

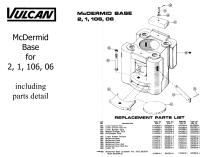

Vulcan McDermid Base for Wood piles only We do not recommend the use of McDermid bases for any type of pile other than wood. But on occasion, contractors have found themselves in a position where they have had to adapt a McDermid base to standard Driving Heads or Pipe Caps. The above shows the arrangement necessary to accomplish this.

Open the catalog to page 13

Vulcan Single Acting: Field Service Manual four Dowel Pins, align the Ram Retainer Split Ring (7) around the Piston Rod and insert into Segmental Pressure Ring as shown. Securely fasten all hold-down nuts. FOR NO. 014, 016, OEO: In the Single Acting Type Pile Hammers the simplest method of installing the Piston and Rod is with the Hammer in a vertical position. To install a new Piston and Rod, remove the following parts from the Hammer In the order specified: 1. Cylinder Head. 5. Ram Keys. 2. Gland and Bushing. 6. Split Bushing. 3. Piston Rod Packing. 7. Old Piston and Rod. 4. Junk...

Open the catalog to page 14

Vulcan Single Acting: Field Service Manual MAINTENANCE For every additional inch the Key must be driven plane or mill 3/64” (.0461 from the flat edge of the Kev. \/U£CJIA/\ RAM KEYS FOR NO. E, 1, OB, O, OR, OB, OIQ: If unable to drive the original Ram Keys so that the small end of the Key projects sufficiently on the opposite side of the Ram to expose the pin hole, reduce the thickness of the Ram Cushion .021 foreach additional inch that the Ram Key has to be driven. If the Ram Keys drive too far through the Ram, interpose a steel shim of the required thickness between the Ram Plate and the...

Open the catalog to page 15

\/ULCAN\ Vulcan Single Acting: Field Service Manual Valve Setting Particular care must be taken in setting the valve on all models of hammers in order to insure maximum efficiency. Detailed instructions for setting of the valve are contained on pages 19 thru 27. If will be noted that the procedure is the same for all models and the only variation found is in the dimensional aspects. Removing Broken Ram Point In order to remove a broken point, the side pins (if any) will have to be drilled out before any force is applied to the Ram Point. A force of 50 to 200 tons or even greater may be...

Open the catalog to page 16

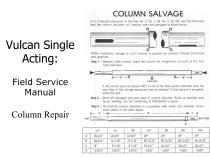

BASE/CYLINDER COLUMN HOLE REPAIR In older Vulcan Single Acting Hammers, it is a commonplace occurrence that the Hammer Base and Cylinder become excessively worn in the area where the shoulder of the column bears on these parts (see Figs. 1 & 3). Column repairs are covered in Tip #32. In lieu of welding (not recommended) the following restoration procedure has been found to be very effective, as well as providing an easy method for repeated repairs. Vulcan Single Acting: Field Service Manual Base/cylinder column hole repair When the top surface of the Base (Fig. 1) becomes worn and...

Open the catalog to page 17

Vulcan Single Acting: Field Service Manual Column Repair

Open the catalog to page 18

REPLACEMENT PARTS LIST KEY NO. DESCRIPTION PART NO. PART NO PART NO. PART NO 054 Lower Column Key 055 Lower Column Key Pin 057 Lower Bumper Stud 058 Washer/Bumper Stud 059 Pin/Bumper Stud 067 Lower Rubber Bumper 090 McDermid Base 091 McDermid Plate 092 McDermid Door 093 McDermid Door Bolt 093 McDermid Door Bolt Nut 094 Cotter Pin McDermid Base Complete Incl. 54,57,58,59,67 90,91,92,93.94.55

Open the catalog to page 19All American Piledriving Equipment Inc. catalogs and technical brochures

-

APE Polar Penetrator

2 Pages

-

Diesel Hammers

28 Pages

-

Drill_rigs

2 Pages

-

APE MODEL 85

2 Pages

-

APE HD™ DRIVERS

2 Pages

-

APE HD™ HELICAL

2 Pages

-

APE Equipment Catalog

25 Pages

-

APE Field Catalog

31 Pages