Catalog excerpts

SAFETY DONE SAFELY!

Open the catalog to page 1

AlphiSafe | Safety done safely!

Open the catalog to page 2

AlphiSafe is a collective protection system for formwork and slab edges. The system's technical innovations allow, in particular, safe installation and automatic locking. Robust AlphiSafe is certified by Ginger CEBTP, as per the EN 13374 standard, classes A and B for certain elements. AlphiSafe is distinguished by its height of 1.30 m, which is above the minimum height of one metre set by the standard, and protects traditional slab formwork up to 30 cm thick. AlphiSafe is the first certified system to have a protective mesh of less than 15 kg, for a length of 2.50 m. Site: New hospital in...

Open the catalog to page 3

AlphiSafe | Safety done safely! SAFETY Safe installation from bottom. Height of 1.3 m. Compliant with the EN 13374 standard or July which specifies that safety systems must be designed "to avoid accidental removal or displacement of any component in any direction during use". SIMPLICITY Anti-dropout. Automatic locking of the grid. Inseparable components. COMPLIANT WITH EN 13374 STANDARD ERGONOMICS Weight of components: less than 15 kg for the mesh and less than 7 kg for the other elements. Helps to reduce repetitive strain inju

Open the catalog to page 4

Primary adapter A comprehensive range of adapters which make all assembly configurations possible The clips are incorporated into the posts which means they cannot be lost. Galvanized post The mesh is available in 3 lengths: 1.25, 2.40 and 2.50 m Other lengths on request It is designed with 2 layers that increase its stiffness and 1 low baseboard (solid board) It is customisable to your choice of colours

Open the catalog to page 5

AlphiSafe ALPHISAFE ACCESSORIES Primary adapter Prop adapter Adapter for town barrier application MaxiDalle adapter Slab clamp adapter Beam adapters Slab base Number of meshes carried Maximum working load (kg) Welded hoisting rings

Open the catalog to page 6

AUTOMATIC LOCKING ED PATENT M S YS T E INNOVATIONS The system's main technical innovations: - utomatic head locking, a - lift protection, - base locking in rotation. - he mesh is locked at the top by the anti-lifting pin and is locked at the base. T

Open the catalog to page 7

AlphiSafe ADAPTABILITY The AlphiSafe system can be adapted to TopDalle, TopDalle Éco and Dalphi formwork and to MaxiDalle. ASSEMBLY ON DALPHI - TOPDALLE - TOPDALLE ÉCO

Open the catalog to page 8

USER GUIDE: PROGRESSIVE INSTALLATION ON FORMWORK: - or progressive installation of the AlphiSafe system, create a stable frame with two primary F beams and one secondary beam at the end of the primary beams to be secured. - ontinue to follow the same installation procedure on the entire frame C to be secured. - sing a rolling safety ladder, fit the AlphiSafe prop adapter in the hole U in the top plate.

Open the catalog to page 9

AlphiSafe USER GUIDE: PROGRESSIVE INSTALLATION 4 - he adapter anti-dropout system locks automatically onto the prop. T - he post anti-dropout system locks automatically onto the adapter. T - it the AlphiSafe post in the adapter. F - Repeat the operation for the entire frame to be secured.

Open the catalog to page 10

- nstall the AlphiSafe mesh of less than 15 kg by sliding it over the I formwork, with the baseboard on the post side and the self-adhesive label facing upwards. - his procedure is facilitated by using the AlphiSafe pole. T - ove the AlphiSafe mesh so that the baseboard is in contact with the M AlphiSafe adapter. - rom the work surface, simply lift the AlphiSafe mesh using the F AlphiSafe pole.

Open the catalog to page 11

AlphiSafe USER GUIDE: PROGRESSIVE INSTALLATION 12 - ngage the top wire of the AlphiSafe mesh in the notches in the E AlphiSafe posts. - he mesh anti-dropout system locks automatically under the effect T of gravity. This does not rule out the need for a visual inspection to ensure that the operation has been conducted correctly. - ake sure that the mesh is positioned correctly. Top wire in the notches M of the 2 posts, and baseboard in the adapter groove. - epeat the operation for the other meshes according to the frame to R be secured.

Open the catalog to page 12

- omplete the secondary beam frames. C

Open the catalog to page 13

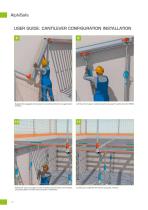

AlphiSafe USER GUIDE: CANTILEVER CONFIGURATION INSTALLATION ON FORMWORK: - nstall the formwork according to the plans provided. I - n the ground, place the new-generation bracket on the technical O support (or the insulated head) that is to receive the primary beam in a cantilever configuration. - aution: the bracket should be installed before installing the technical C support.

Open the catalog to page 14

- ontinue the installation of the primary beam on the rear prop, position C the prop with the bracket at the end of the primary beam. - omplete the secondary beam frames using the TopPerche. C - it the Non-tilt safety fork (FSAB) on the primary beam in a cantilever F configuration not exceeding the rule of ⅓ - ⅔ of the size of the beam. - nstall the AlphiSafe primary adapter with its AlphiSafe post. The complete I anti-dropout system is activated automatically.

Open the catalog to page 15

AlphiSafe USER GUIDE: CANTILEVER CONFIGURATION INSTALLATION 8 - uspend the equipped primary beam by inserting it into the new-generation S bracket. - ift the primary beam using the technical support inserted into the FSAB. L - ollow the same procedure with another primary beam and install a F secondary beam at their ends using the TopPerche. - ontinue to install the formwork using this method. C

Open the catalog to page 16

- nstall the AlphiSafe mesh of less than 15 kg by sliding it over the I formwork, with the baseboard on the post side and the self-adhesive label facing upwards. - his procedure is facilitated by using the AlphiSafe pole. T - ove the AlphiSafe mesh so that the baseboard is in contact with the M AlphiSafe adapter. - rom the work surface, simply lift the AlphiSafe mesh using the F AlphiSafe pole. - ngage the top wire of the AlphiSafe mesh in the notches in the E AlphiSafe posts.

Open the catalog to page 17

AlphiSafe USER GUIDE: CANTILEVER CONFIGURATION INSTALLATION 16 - he mesh anti-dropout system locks automatically under the effect T of gravity. This does not rule out the need for a visual inspection to ensure that the operation has been conducted correctly. - ake sure that the mesh is positioned correctly. Top wire in the notches M of the 2 posts, and baseboard in the adapter groove. - epeat the operation for the other meshes according to the frame to R be secured. - omplete the secondary beam frames. C

Open the catalog to page 18All ALPHI SAS catalogs and technical brochures

-

THE EXTRA-LARGE FORMWORK PANEL

32 Pages

-

A COMPLETE DECK RANGE

13 Pages

-

TWO RANGES FOR ALL PROJECTS

8 Pages

-

FOR LARGE SURFACES AND BALCONIES

10 Pages

-

VerticAL

7 Pages

-

Dalphi

30 Pages

-

MaxiDalle

32 Pages

-

TopDalle Eco

31 Pages

-

TopDalle

31 Pages