Website:

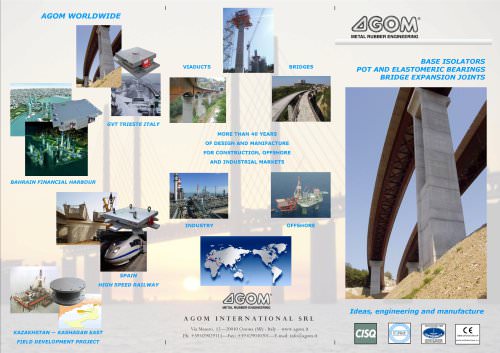

Agom Metal Rubber engineering

Website:

Agom Metal Rubber engineering

Catalog excerpts

Ideas, engineering and manufacture LONGITUDINAL EXPANSION JOINT—AGLJ WITH AGRIP SYSTEM Comprehensive Labelling Thanks to the special design of the rubber cover (AGRIP SYSTEM), the joint produces little noise as vehicles pass over it. All expansion joints are provided with a non-fading mark directly moulded on the rubber outlining Ease of Assembly AGLJ joints come in one meter lengths and are extremely easy to fit; the elements are connected together with a male-female coupling and secured to the structure with anchor bolts. To allow widening of existing bridges, saving money without compromising road safety, Agom has designed the AGLJ Longitudinal Expansion Joint with the AGRIP System which absorbs and enables movement between the two bridge decks. Agom AGLJ Longitudinal Expansion Joints are designed to handle any longitudinal displacements between the adjoining bridge decks they are fastened to. Agom AGLJ Joints also allow transversal displacement of up to 30 mm, depression, and rotation of each part of the structure. They are completely waterproof and are secured to the structure with anchor bolts. The deformable rubber elements are vulcanised bonded with tough steel reinforcements (standard EN 10025). Advantages of AGLJ Expansion Joints Corrosion Resistance The steel structure is completely covered in rubber so protecting it from corrosion. Waterproof AGLJ joints are entirely waterproof. An additional stainless steel draining structure fixed under the mats collect any exhaust water preventing any leakage. Furthermore, two draining pipes, at both sides of the mat capture water coming from sidewalls. - the properties of the joint. - international standard. - order number. - date of manufacturing AGRIP System The AGRIP special antiskid surface, increases grip between the joint and the car’s tyres to improve road safety when driving in rainy or snowy conditions. No additional and periodical maintenance operations are necessary to maintain and preserve the antiskid surface efficacy. Guarantee Long Service Life The tough steel reinforcement and special anti-abrasive rubber used to manufacture Agom joints has been designed to withstand the impact of heavy traffic, the action of oil, grease and petrol, and the effects of ageing due to constant exposure to sunlight and temperature changes. Agom International srl – via Mesero, 12 – 20010 Ossona (MI) Agom expansion joint AGLJ are warranted against any defects due to the manufacturing process and raw materials. The warranty cover the products supplied by Agom and expires if the products are incorrectly store, handle, installed and maintain. For the correct installation, please refer to the Agom Expansion Joints installation instructions. Quality Agom expansion joints are designed and manufactured in accordance with the requirements of the new info@agom.it – www.agom.it bridge expansion joints

Open the catalog to page 1

Ideas, engineering and manufacture European standard. Agom can also supply expansion joints complying with other standards. Every single component is moulded and assembled by fully qualified and trained workers at the Agom factory with regular external inspections according to EN 1337 and under strict ISO 9001:2000 quality control standards. Cutting of paving, demolition and cleaning of the slab. - Installation of drainage pipe and casting of levelling epoxy resin. - After a thorough finishing, where required laying of stainless steel draining structure. - Laying of the expansion joints. -...

Open the catalog to page 2All Agom Metal Rubber engineering catalogs and technical brochures

-

V-MAX POT BEARINGS

26 Pages

-

E -LINK Elastomeric bearings

33 Pages

-

BURIED JOINTS

15 Pages

-

CANTILEVER STEEL JOINTS

25 Pages

-

General Catalogue

2 Pages

-

E-LINK ELASTOMERIC BEARINGS

28 Pages

-

H-MAX BEARINGS

18 Pages

-

EXPANSION JOINTS

9 Pages