Website:

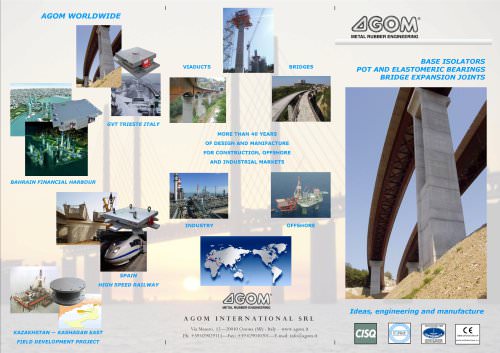

Agom Metal Rubber engineering

Website:

Agom Metal Rubber engineering

Catalog excerpts

ELASTOMERIC BEARINGS Via Mesero, 12 – 20010 Ossona (MI) – Italy - www.agom.it PH.: +39 02 9029111 – FAX: +39 02 9010201 – agom@agom.it

Open the catalog to page 1

E-Link elastomeric bearings Agom's elastomeric bearings are built to withstand loads and simultaneous deformation in any direction, while also allowing for minor rotations in any of the bearing's axes. Agom E-Link bearings can be made entirely of rubber or can be reinforced with special sheet steel to increase capacity and transversal strength. Bearings can also be produced with special anchor plates or with sliding surfaces to improve the structure's displacement capacity. This kind of bearing can withstand vertical loads of up to 22000 kN. E-Link F plain pad bearings Agom E-Link F...

Open the catalog to page 2

E-Link Bearing Type C3 Elastomeric bearings with two external plates and threaded holes for use on metal structures, or as an anti-lift device; in this latter case, suitable anchor bars must be fitted to the bearings for anchoring purposes. E-Link Bearing Type C4 Elastomeric bearings with external plates and pins that connect to suitable steel plates in order to secure the bearing to the structure. E-Link Bearing Type C5 Elastomeric bearings with two suitably etched external plates to facilitate the bearing's bonding to the structure with glue. E-Link Bearing Type BF Elastomer friction...

Open the catalog to page 3

Austenitic steel sheet The austenitic steel used for sliding surfaces is X5CrNiMo17-12-2 in accordance with EN 10088-2 1.4401 with a minimum thickness of 1.5 mm The roughness is Ry5i ≤ 1 μm The hardness ≥ 150 HV1 and ≤ 220 HV1 PTFE Agom uses only virgin PTFE without regenerated or filler materials. The minimum thickness for bonded with the bearings size and type. The minimum thickness of recessed PTFE is 4.5 mm and varies in according with the bearings size. Test method Friction of the bearings The reaction of the bearing to the movement can be mathematically calculated by considering...

Open the catalog to page 4

Fixing types Usually the E-Link bearings with outer fixing steel plates are equipped with suitable anchor bars for anchoring purpose to lower and upper structure. In case of pre-cast concrete beam the bearings can be provided with upper pin and top subsidiary plate; in case of steel beams the bearings shall be provided with upper pin and/or connecting bolts. To adjust the angle of inclination of the superstructure, the elastomeric bearing’s top plate can be manufactured tapered or a wedge plate can be fixed at the top of the bearing. In case of horizontal loads < 20% of the simultaneous...

Open the catalog to page 5

Dust protection The dust protection around the sliding plate ensure the cleaning of the sliding surfaces to minimize the friction during sliding and guarantee the durability of the PTFE sliding material. Corrosion protection Steel components exposed to the elements are protected against corrosion. Agom adapts the corrosion protection in accordance to the aggressiveness of the environment in which the bearings are to be installed and to each customer’s requirements. The standard corrosion protection according EN 1337-9 is as follows: - sandblasting SA2.5 grade - two components high thickness...

Open the catalog to page 6

DESIGN OF A STRCTURE WITH E-LINK BEARINGS SELECTION OF THE STRUCTURE STATIC LINK SCHEME (ALL SIMPLE ELASTOMERIC BEARINGS OR FIXED AND MOVABLE BEARINGS) CALCULATION OF THE LOADS (VERTICAL AND HORIZONTAL) ON THE BEARINGS ACCORDING TO THE SELECTED FIXITY SCHEME CALCULATION OF THE BEARINGS ROTATIONS AND MOVEMENTS FILL IN THE BEARINGS DESIGN TABLE DATA (EXAMPLE TABLE B.1 OF EN1337-1 CODE) USE THE E-Ling BEARING DRAWINGS IUSSUED BY AGOM TO DESGIN THE STRCTURE INFERFACE UNDER AND ABOVE THE BEARING IF NECESSARY, DESIGN THE SLOPED WEDGE TO BE PLACED BETWEEN STRUCTURE AND BEARING

Open the catalog to page 7

Comparison of bearings performances V-MAX spherical bearing rubber bearings Vertical load Horizontal displacement Advantages of using Agom E-Link elastomeric bearings The Agom E-Link bearings fulfil the following requirements: a. Transmit the vertical loads due to permanent and accidental effects; it is possible to cover a wide range of loads about up to 22000 kN Transmit the horizontal loads with or without elastic response Allow rotation as per a spherical hinge Suitable for all structures steel and concrete bridges and buildings Capacity of horizontal displacement High durability and no...

Open the catalog to page 8

Qualification, approval tests and certifications All the qualification and approval tests are performed by independent and worldwide recognized laboratories to assure that the E-Link bearings’ performances comply with the project and with international standard requirements. DYNAMIC TESTS ON COMPOUNDS TYPE TESTS

Open the catalog to page 9

Handling and storage installation and maintenance This manual gives the main list of the most important operations to correctly install the AGOM bridge bearings. Under control of the Engineer who designed the bridge, bearings must be installed by expert workers, with precision to meet the bridge and bearing design criteria. Inappropriate handling, storage and installation will have an adverse effect on the bearing life, usually estimated in more than 50 years providing right maintenance. AGOM structural bearings are manufactured to close tolerances by skilled technicians working in clean...

Open the catalog to page 10

Installation The installation procedure of the bearings generally depends on the structure type. Here the main steps for bearing with anchor bars are shown. If there are no anchor bars the procedure is similar without any requirements for the voids to place the bars. 1. Check before installation. In order to avoid placements mistakes of the bearings, all the technical and description data, printed on the label, shall be checked and compared with the ones showed in the shop drawings. 2. Casting of the substructures. Substructures shall reach a level about 30 mm lower then the final level. In...

Open the catalog to page 11

4. Casting of the superstructure – cast-in-situ superstructure Superstructure formwork must be arranged around the bearing upper steel plate and sealed with adhesive tape or foam to avoid concrete leakage during casting. The formwork must be arranged in a suitable way to avoid embedding of the bearing upper plate into concrete to avoid bearing embedding compromising the eventual future replacement. The formwork must be supported at the design level during concrete pouring. Formwork placing and concrete pouring When the concrete has reached adequate resistance the supports and formwork have...

Open the catalog to page 12All Agom Metal Rubber engineering catalogs and technical brochures

-

V-MAX POT BEARINGS

26 Pages

-

E -LINK Elastomeric bearings

33 Pages

-

BURIED JOINTS

15 Pages

-

CANTILEVER STEEL JOINTS

25 Pages

-

General Catalogue

2 Pages

-

H-MAX BEARINGS

18 Pages

-

EXPANSION JOINTS

9 Pages