Website:

Agom Metal Rubber engineering

Website:

Agom Metal Rubber engineering

Catalog excerpts

Via Mesero, 12 – 20010 Ossona (MI) – Italy - www.agom.it PH.: +39 02 9029111 – FAX: +39 02 9010201 – agom@agom.it CANTILEVER STEEL JOINTS

Open the catalog to page 1

IDEAS, ENGINEERING AND MANUFACTURE Bridges are subjected to movements and rotation caused by traffic, temperature changes, earthquakes, shrinkage, post-tensioning, creep, etc. Bridge construction requires carefully designed and manufactured bearings, anti-seismic devices, shock absorbers and expansion joints to ensure that such forces are properly dealt with throughout the life of the structure. AGOM has over 50 years experience in design and manufacturing of bridge bearings, bridge expansion joints, anti-seismic devices and shock absorbers for the bridge-building and construction industry....

Open the catalog to page 2

Bridge Deck Movements The horizontal movements of a bridge superstructure are due to : • Temperature expansion and contraction • Shrinkage of concrete • Shortening of concrete due to creep effect • Elastic shortening • Movements due to induced external loads (e.g. earthquake, wind, vehicular braking etc.) Temperature Temperature variations cause both expansion and shortening of the bridge deck and are usually computed as a plus and minus range about a mean structure temperature which occurs when the superstructure is placed on the bearings. Temperature differentials also occur in the deck...

Open the catalog to page 3

AGFJ cantilever metallic joints AGFJ steel expansion joint elements are specially designed and manufactured for traffic safety in accordance with ETAG n.32. The gap between structures is overpassed by steel cantilever, finger shape elements that intersect, thus reducing the voids to small spaces. Steel elements are fixed to reinforced concrete using suitable corrosion-resistant galvanized anchor bolts to absorb elastic reactions, mechanical vibrations and other movements of the structure. For the larger joints (from AGFJ 150 included) folded steel plates, to be used also as formworks, are...

Open the catalog to page 4

Features AGFJ expansion joints has the following main characteristics: • movement capacity from ±25 mm up to ±400 mm; • structural elements from steel S355JR EN10025 galvanised or S355J0W EN10155; • galvanised anchors with self-locking nuts; • continuous watertight strip system; • smooth transit over the expansion joints; • footpath cover plates can be provided if required; • vertical misalignment can be compensated during installation. So their benefits can be summarized as below.

Open the catalog to page 5

Dimensions AGFJ expansion joints are supplied in standard elements with length about 1 m and has the following dimensions: Anchor bars spacing (mm) Anchor bars *at installation, in average position

Open the catalog to page 6

Installation The following installation procedure is very important and shall be fully read and understood prior to beginning any works. To ensure proper installation and performance of expansion joint system the following actions must be complied by skilled people. Errors during installation will affect product warranty. a) b) c) d) Read and understand installation procedure. Inspect all the materials supplied. Inspect the adjacent concrete structure for acceptance before beginning works. Study and verify the shop drawings. 1. Preparation of the joint zone. Scarify the concrete deck near...

Open the catalog to page 7

3. Positioning. Hang the so obtained formworks to steel beams in order to put them at the design altitude. For the smaller joints (AGFJ 100 included), you’ll have to hang the complete joint package (finger element + waterproof strip + angular steel plate). 4. Casting. Cast the concrete under the formwork; if necessary, use a primer to improve the adhesion on the existing concrete. Wait till concrete blocks have reached the correct hardening. 5. Installation of waterproof strip. For the smaller joints (AGFJ 100 included), the waterproof strip is already in its position. For the larger...

Open the catalog to page 8

6. Anchors fixing. When all the finger elements are in their position, fix them with washers, nuts and locknuts. 7. Finishing. Put the asphalt up to the finger plates. Seal the possible space between asphalt and finger plates by using mastic asphalt. AGOM reserves the right to make changes to the project thus reported in this catalogue in order to improve the product.

Open the catalog to page 9

Materials Structural steel properties comply with EN 10025.

Open the catalog to page 10

Maintenance and replacement AGOM AGFJ expansion joints, if correctly installed, are theoretically free from maintenance. Normally the joint element does not required any surface regular cleaning, because its shape and the movement cycles will push dirt out. In any case if during inspection some objects (typically small stones, etc..) are inside the fingers they have to be removed for joint perfect functioning. We suggest to perform the following inspections to guarantee the joint right functioning: 1. a first inspection just at the end of installation to verify the right positioning and...

Open the catalog to page 11

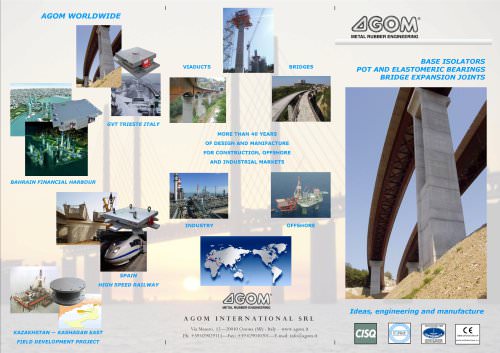

MORE THAN 50 YEARS EXPERIENCE DESIGNING AND MANIFACTURING DEVICES FOR CONSTRUCTION, OFFSHORE AND INDUSTRIAL MARKETS Bridge bearings • Elastomeric Bridge bearings • Pot bearings • Spherical bearings • Incremental Launching bearings • Horizontal load bearings • Special bearings Seismic Isolators • High damping rubber bearings • Lead core rubber bearings • Multilayer rubber bearings • Shock transmitters • Shock absorber • Rubber dampers Expansion joints • Elastomeric joints • Joints for high movements • Finger joints • Buried joints • Railway joints Services • Design • Consulting • On site...

Open the catalog to page 12

Via Mesero, 12 – 20010 Ossona (MI) – Italy - www.agom.it PH.: +39 02 9029111 – FAX: +39 02 9010201 – agom@agom.it CANTILEVER METALLIC JOINTS

Open the catalog to page 13

IDEAS, ENGINEERING AND MANUFACTURE Bridges are subjected to movements and rotation caused by traffic, temperature changes, earthquakes, shrinkage, post-tensioning, creep, etc. Bridge construction requires carefully designed and manufactured bearings, anti-seismic devices, shock absorbers and expansion joints to ensure that such forces are properly dealt with throughout the life of the structure. AGOM has over 50 years experience in design and manufacturing of bridge bearings, bridge expansion joints, anti-seismic devices and shock absorbers for the bridge-building and construction industry....

Open the catalog to page 14All Agom Metal Rubber engineering catalogs and technical brochures

-

V-MAX POT BEARINGS

26 Pages

-

E -LINK Elastomeric bearings

33 Pages

-

BURIED JOINTS

15 Pages

-

General Catalogue

2 Pages

-

E-LINK ELASTOMERIC BEARINGS

28 Pages

-

H-MAX BEARINGS

18 Pages

-

EXPANSION JOINTS

9 Pages