Website:

Agom Metal Rubber engineering

Website:

Agom Metal Rubber engineering

Catalog excerpts

Via Mesero, 12 – 20010 Ossona (MI) – Italy - www.agom.it PH.: +39 02 9029111 – FAX: +39 02 9010201 – agom@agom.it BURIED JOINTS

Open the catalog to page 1

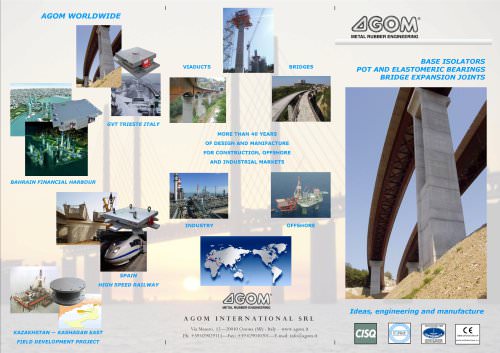

Building and engineering Bridges are subjected to movements and rotation caused by traffic, temperature changes, earthquakes, shrinkage, post-tensioning, creep, etc. Bridge construction requires carefully designed and manufactured bearings, anti-seismic devices, shock absorbers and expansion joints to ensure that such forces are properly dealt with throughout the life of the structure. AGOM has over 50 years experience in design and manufacturing of bridge bearings, bridge expansion joints, anti-seismic devices and shock absorbers for the bridge-building and construction industry. All...

Open the catalog to page 2

Bridge Deck Movements The horizontal movements of a bridge superstructure are due to : • Temperature expansion and contraction • Shrinkage of concrete • Shortening of concrete due to creep effect • Elastic shortening • Movements due to induced external loads (e.g. earthquake, wind, vehicular braking etc.) Temperature Temperature variations cause both expansion and shortening of the bridge deck and are usually computed as a plus and minus range about a mean structure temperature which occurs when the superstructure is placed on the bearings. Temperature differentials also occur in the deck...

Open the catalog to page 3

Buried joints series Buried expansion joints are designed and manufactured for small movements between structures, up to ±25 mm. These joints are generally put under the asphalt, in order to guarantee the continuity of the surface of vehicle transit. They are often associated to kinematic chain system, that will absorb the longitudinal forces.

Open the catalog to page 4

AGEJS buried joint AGEJS buried expansion joint is made of a rubber extruded profile that is reinforced with a steel plate. It can accommodate movements between structures up to ±17.5 mm. This joint is generally put under the asphalt, in order to guarantee the continuity of the surface of vehicle transit. Typical current section MATERIALS The rubber used for this kind of joint is EPDM. The reinforcement plate is made of steel S235JR EN10025, zinc coated to resist to corrosion. Waterproofing can be increased by a strip stuck on the vertical edges of the opposite structures. INSTALLATION The...

Open the catalog to page 5

AGFJS buried joint AGFJS buried expansion joint is made of a couple of steel profiles connected to the concrete structures, with a rubber extruded profile inserted in the gap. It can accommodate movements between structures up to ±25 mm. This joint is generally put under the asphalt, in order to guarantee the continuity of the surface of vehicle transit. Typical current section MATERIALS The rubber used for the extruded profile is EPDM. The angular profiles are made of steel S235JR EN10025, to whom stirrups are welded to guarantee connection with concrete structures. INSTALLATION The phases...

Open the catalog to page 6

2. Position a template between structures (polystyrene) with the width of design gap. 3. Position the steel modulus on adequate supports (i.e. wooden), using the template as reference for final gap. Don’t remove the red plates in this phase. 4. Tie the stirrups of the joint with the existing rebars. 5. Cast the completing concrete.

Open the catalog to page 7

6. Remove the red temporary plates and the polystyrene template. The rubber profile can be inserted also at this step: it’s crucial it’s compressed between the angular steel profiles.

Open the catalog to page 8

AGKJS buried joint AGKS buried expansion joint is made of structures, with a rubber extruded profile between structures up to ±20 mm. This guarantee the continuity of the surface of a couple of steel profiles connected to the concrete inserted in the gap. It can accommodate movements joint is generally put under the asphalt, in order to vehicle transit. Typical current section MATERIALS The rubber used for the extruded profile is EPDM. The angular profiles are made of steel S235JR EN10025, to whom stirrups are welded to guarantee connection with concrete structures. INSTALLATION The phases...

Open the catalog to page 9

2. Position a template between structures (polystyrene) with the width of design gap. 3. Position the steel modulus on adequate supports (i.e. wooden), using the template as reference for final gap. Don’t remove the red plates in this phase. 4. Tie the stirrups of the joint with the existing rebars. 5. Cast the completing concrete.

Open the catalog to page 10

6. Remove the red temporary plates and the polystyrene template. The rubber profile can be inserted also at this step: it’s crucial it’s compressed between the angular steel profiles. 7. Insert the rubber profile: it’s crucial it’s compressed between the angular steel profiles.

Open the catalog to page 11

Materials Structural steel properties comply with EN 10025.

Open the catalog to page 12

Maintenance and replacement AGOM AG_JS expansion joints are designed to be free from maintenance, as they are put in a zone generally not reachable. We suggest to perform the following inspections to guarantee the joint right functioning: 1. a first inspection just at the end of installation to verify the right positioning; an inspection after a year of service, in order to visually detect any eventual damage of the asphalt in the adjacent zones of joint; during inspection, the asphalt surface must be checked in order to verify there are no significant damages due to transit of unexpected...

Open the catalog to page 13

AFTER INSTALLATION INSPECTION PRINCIPAL INSPECTION REGULAR INSPECTION REGULAR INSPECTION PRINCIPAL INSPECTION If replacement is necessary, installation phases shall be repeated, after demolishing the concrete parts included in the blockout and removing the existing joint.

Open the catalog to page 14

MORE THAN 50 YEARS EXPERIENCE DESIGNING AND MANIFACTURING DEVICES FOR CONSTRUCTION, OFFSHORE AND INDUSTRIAL MARKETS Bridge bearings • Elastomeric Bridge bearings • Pot bearings • Spherical bearings • Incremental Launching bearings • Horizontal load bearings • Special bearings Seismic Isolators • High damping rubber bearings • Lead core rubber bearings • Multilayer rubber bearings • Shock transmitters • Shock absorber • Rubber dampers Expansion joints • Elastomeric joints • Joints for high movements • Finger joints • Buried joints • Railway joints Services • Design • Consulting • On site...

Open the catalog to page 15All Agom Metal Rubber engineering catalogs and technical brochures

-

V-MAX POT BEARINGS

26 Pages

-

E -LINK Elastomeric bearings

33 Pages

-

CANTILEVER STEEL JOINTS

25 Pages

-

General Catalogue

2 Pages

-

E-LINK ELASTOMERIC BEARINGS

28 Pages

-

H-MAX BEARINGS

18 Pages

-

EXPANSION JOINTS

9 Pages