Catalog excerpts

Purelight Interior Technical Sheet Reduces up to 88.8% of the pollutants in the air Eliminates 99.9% of moulds and bacteria even without light, permanently preventing their growth Prevents dirt depositing on the surfaces Eliminates bad odours from the surrounding environment Ensures an excellent aesthetic performance with the application of a single coat Diluition with water 75% Airlite Purelight Interior is a mineral, inorganic interior paint with high breathability. It is available in white and numerous colours. Provided in a powder form, it has to be mixed with water before application guaranteeing perfect coverage and a long-lasting effect. The technology of Airlite is recommended by the Italian Ministry of Environment via Article (G.U. n. 84 - 9 April 2004) – Innovative Systems and Technologies for the mitigation and removal of environmental pollution. Airlite Purelight Interior is Cradle to Cradle Certified™ at the silver level. Cradle to Cradle Certified™ products are evaluated for material health, material reutilization, renewable energy use and carbon management, water stewardship, and social fairness. Airlite Purelight Interior uses a set of patented technologies in order to reduce air pollution, to eliminate moulds and bacteria from the surfaces of the walls and to eliminate bad odours. Furthermore, it prevents deposit of dirt particles from the air on the walls, keeping them clean for a long period. Activated in the presence of light, the effectiveness is preserved with limited to no reduction of performance due to the catalytic nature of the technology. With the application of a coat of tinted Airlite Primer and a single coat of Airlite Purelight Interior, an excellent aesthetic performance and a finely velvety natural finish is guaranteed, reducing the time of the application. The special inorganic composition of the paint is in class A2-s1, d0 regarding fire classification (UNI EN 13501-1:2009). The VOC content is less than 0.1 g/l in the white coloured product when being applied (European Directive 2004/42/CE), more than 300 times less than the limit defined in the European Regulations. Airlite is LEED, WELL and BREEAM compliant: Airlite products can help you get points for LEED, WELL and BREEAM certification of buildings. Airlite Purelight Interior has high coverage and can be applied on all the internal surfaces (new, already built or already painted) where a nice smooth matt finish is desired. Particularly: - painting of masonry, plaster, concrete, lime or plaster whether they are seasoned or old, as long as they are cohesive, adherent and not powdery - re-painting on previously applied paint in indoors, as long as they are adherent to the surface - painting of plasterboard The product is recommended especially in environments where we want to guarantee the maximum level of hygiene, such as in schools, public offices, hospitals, surgeries or in private residencies where a high living comfort is desired, improving the quality of the air, especially in presence of children, elderly and people with respiratory problems, in so far as it continuously improves the quality of the treated environment. The base must be intact, solid, dry, clean, free of dust, oil, efflorescence, incoherent particles, substances or salts that might prevent the adhesion of the paint. The substrate must be treated with tinted Airlite Primer (white or coloured). Particular cases Old Substrates: the surfaces must be treated carefully. Moulds must be removed prior to application of Airlite Anti-Mould. Any remaining paint, old overcoats and overlays must be removed so the surface must be cleaned again. Concrete: the surfaces must be treated carefully. Any remains must be removed and surface flaws repaired before the application of the product. Any remaining oil, grease and wax must be removed with sandblasting machine. Clean with water Application Cycle The complete application cycle includes the preparation of the substrate with a single coat of tinted Airlite Primer, and a single coat of Airlite Purelight Interior. - Short-haired roller - Brush - Roller grid - Empty can - Water - Scale - Measuring cup - Drill mixer Application Instructions The following instructions have been compiled to ensure the correct application of Airlite. Please follow them closely. It is essential that the correct ratio/combination of Airlite Powder and water is respected (see below). Airlite is 100% natural and in order to get the best results possible, it is recommended to complete the painting of the surface without interruption in order to have an even finish. The application of a single coat of tinted Airlite Primer is essential before the application of Airlite Purelight Interior. For any enquire, please contact our customer service department by writing to: info@airlite.com Instructions for the preparation of 5 kg of Airlite powder. For different quantity, the same proportions and procedures must be applied (eg.: each 1 kg of Airlite powder has to be mixed with 0,75 litres of water). White Paint* 1. Take 3.75 litres of clean water. 2. Pour 2 litres of the prepared water into 5 kg of Airlite Purelight Interior powder. 3. Mix it with a mixer until the powder is completely dissolved. It is recommended to start with a lower speed and increase it gradually to a higher speed. 4. Add the remaining 1.75 litres of water to the mix. 5. Continue mixing it alternating the speed of the mixer, until you have the optimal consistency. Coloured paint* 1. Fill up a container with 3.75 litres of clean water. 2. Take the container of the pigment. 3. Pour all the coloured pigment into the 3.75 litres of water, mix it at least for 20 seconds, until it is completely dissolved. 4. Pour 2 litres of the coloured water into the 5 kg of Airlite Purelight Interior powder. 5. Mix it with a mixer until the powder is completely dissolved. It is recommended to start with a lower speed and increase it gradually to a higher speed. 6. Add the remaining 1.75 litres of water to the mix. 7. Continue mixing it alternating the speed of the mixer, until you have the optimal consistency. Attention: once the paint is ready, it has to be applied in 3 hours (this is an indicative value, it depends on the environmental conditions). For airless spray gun application, use a nozzle type 427-429 and a pressure of approx. 100/140 bar. The tools used must be rinsed thoroughly with water immediately after u

Open the catalog to page 1All Advanced Materials catalogs and technical brochures

-

Airlite Primer HP

1 Pages

-

Airlite Anti-Mould

1 Pages

-

Clear Coat

1 Pages

-

Airlite Primer

1 Pages

-

Ioniqa Interior

1 Pages

-

Hystoriqa Stone

2 Pages

-

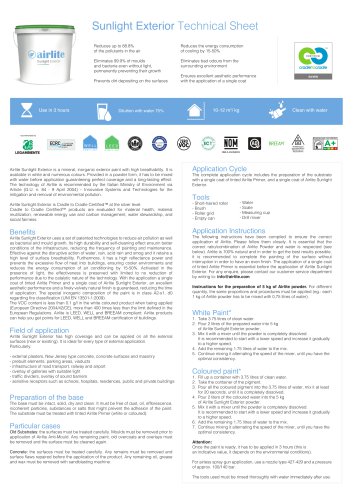

Sunlight Exterior

3 Pages