Catalog excerpts

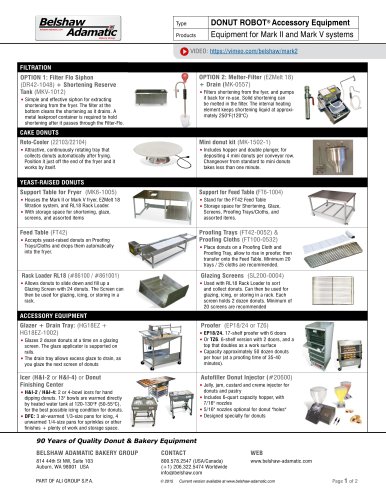

Type Products DONUT ROBOT® Accessory Equipment Equipment for Mark II and Mark V systems VIDEO: https://vimeo.com/belshaw/mark2 FILTRATION OPTION 2: Melter-Filter (EZMelt 18) + Drain (MK-0557) OPTION 1: Filter Flo Siphon (DR42-1048) + Shortening Reserve Tank (MKV-1012) ••Filters shortening from the fyer, and pumps it back for re-use. Solid shortening can be melted in the filter. The internal heating element keeps shortening liquid at approximately 250°F(120°C) ••Simple and effective siphon for extracting shortening from the fryer. The filter at the bottom cleans the shortening as it drains. A metal leakproof container is required to hold shortening after it passes through the Filter-Flo. CAKE DONUTS Roto-Cooler (22103/22104) ••Attractive, continuously rotating tray that ••Includes hopper and double plunger, for collects donuts automatically after frying. Position it just off the end of the fryer and it works by itself. depositing 4 mini donuts per conveyor row. Changeover from standard to mini donuts takes less than one minute. YEAST-RAISED DONUTS Support Table for Fryer (MK6-1005) Support for Feed Table (FT6-1004) ••Houses the Mark II or Mark V fryer, EZMelt 18 filtration system, and RL18 Rack Loader. ••With storage space for shortening, glaze, screens, and assorted items ••Stand for the FT42 Feed Table ••Storage space for Shortening, Glaze, Proofing Trays (FT42-0052) & Proofing Cloths (FT100-0532) Screens, Proofing Trays/Cloths, and assorted items. ••Accepts yeast-raised donuts on Proofing Trays/Cloths and drops them automatically into the fryer. ••Place donuts on a Proofing Cloth and ••Allows donuts to slide down and fill up a Glazing Screen with 24 donuts. The Screen can then be used for glazing, icing, or storing in a rack. ••Used with RL18 Rack Loader to sort Proofing Tray, allow to rise in proofer, then transfer onto the Feed Table. Minimum 20 trays / 25 cloths are recommended. and collect donuts. Can then be used for glazing, icing, or storing in a rack. Each screen holds 2 dozen donuts. Minimum of 20 screens are recommended ACCESSORY EQUIPMENT Proofer (EP18/24 or TZ6) Glazer + Drain Tray: (HG18EZ + HG18EZ-1002) ••EP18/24. 17-shelf proofer with 6 doors ••Or TZ6. 6-shelf version with 2 doors, and a ••Glazes 2 dozen donuts at a time on a glazing top that doubles as a work surface screen. The glaze applicator is supported on rails. ••The drain tray allows excess glaze to drain, as you glaze the next screen of donuts ••Capacity approximately 50 dozen donuts per hour (at a proofing time of 35-40 minutes). Icer (H&I-2 or H&I-4) or Donut Finishing Center Autofiller Donut Injector (#20600) ••Jelly, jam, custard and creme injector for donuts and pastry ••Includes 6-quart capacity hopper, with dipping donuts. 13" bowls are warmed directly by heated water tank at 120-130°F (50-55°C), for the best possible icing condition for donuts. ••DFC: 3 air-warmed 1/3-size pans for icing, 4 unwarmed 1/4-size pans for sprinkles or other finishes + plenty of work and storage space. ••5/16" nozzles optional for donut "holes" ••Designed specially for donuts 90 Years of Quality Donut & Bakery Equipment BELSHAW ADAMATIC BAKERY GROUP 800.578.2547 (USA/Canada) (+1) 206.322.5474 Worldwide info@belshaw.com

Open the catalog to page 1

Donut Robot® PLUNGERS AND ATTACHMENTS (for all Donut Robot® Depositors, including Mark VI Dual Depositor) Item Number Attachments • Attachments are simple devices that divide the normal deposit into halves, thirds, or quarters. Attachments are inserted onto a Plain plunger or Star plunger. Plunger size and product weight • You can adjust the amount of batter deposited to make a larger or smaller donut, between the MIN and MAX weights shown below. Product weights are estimates only. 90 Years of Quality Donut & Bakery Equipment BELSHAW ADAMATIC BAKERY GROUP CONTACT WEB 814 44th St NW,...

Open the catalog to page 2All ADAMATIC catalogs and technical brochures

-

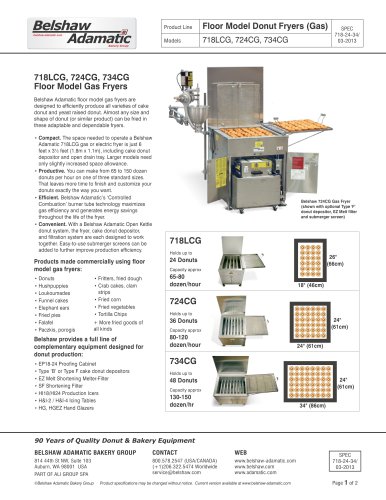

Belshaw 718L-724-734

2 Pages

-

Harmony Modular Deck

8 Pages

-

Dough Dividers

8 Pages

-

Moulders

8 Pages

-

BL Bowl Lift

2 Pages

-

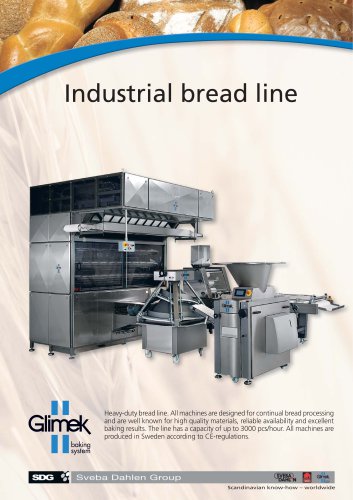

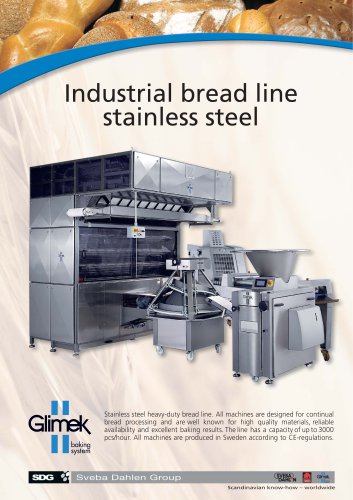

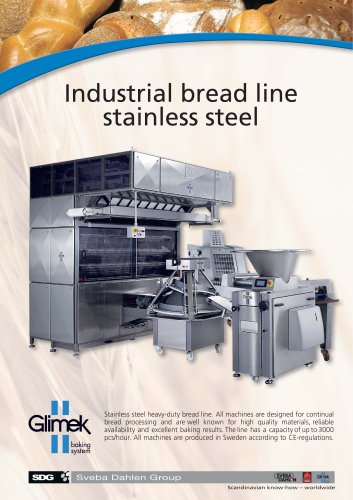

Bread Lines

12 Pages

-

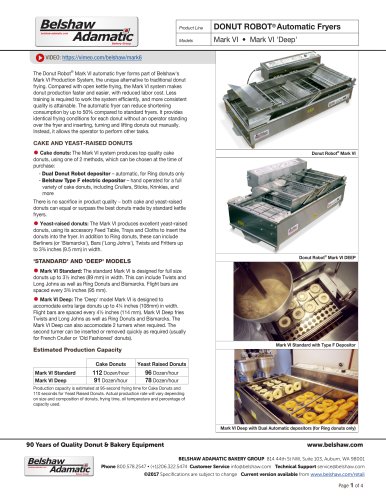

Mark VI ‘Deep’ System

2 Pages

-

TYPE K PANCAKE DISPENSER

2 Pages

-

Hushpuppy Depositor

2 Pages

-

Type F-YRD

2 Pages

-

Type F

2 Pages

-

PRF-2022

2 Pages

-

PRF-2021

2 Pages

-

OVEN-2010

2 Pages

-

DX Oven

2 Pages

-

OVEN 2020

4 Pages

-

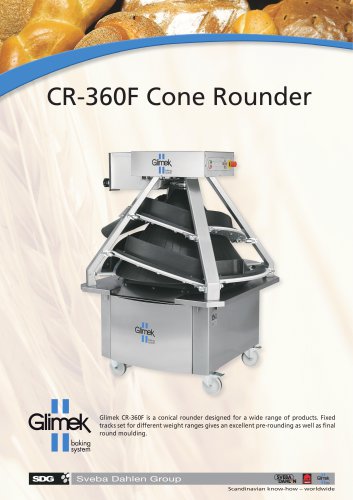

Glimek CR-360 Cone Rounder

2 Pages

-

Adamatic VDR Divider Rounder

2 Pages

-

Adamatic NDR Divider Rounder

2 Pages

-

Glimek Artisan Bread Line

2 Pages

-

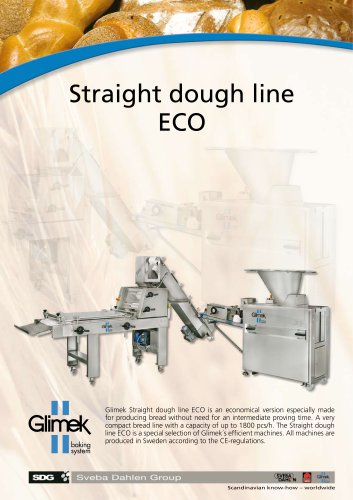

Glimek Straight Dough Line

2 Pages

-

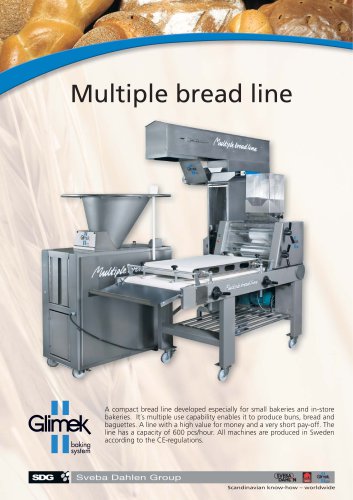

Glimek Multiple Bread Line

2 Pages

-

Glimek Eco-line

2 Pages

-

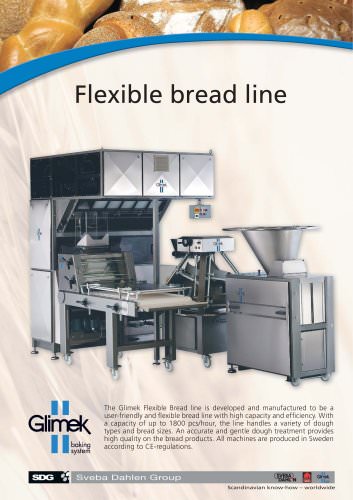

Glimek Flexible Bread Line

2 Pages

-

Glimek SD-300 Dough Divider

2 Pages

-

Glimek CR-360F Cone Rounder

2 Pages

-

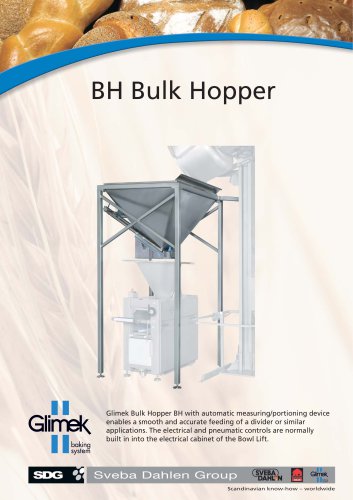

Glimek BH Bulk Hopper

2 Pages

-

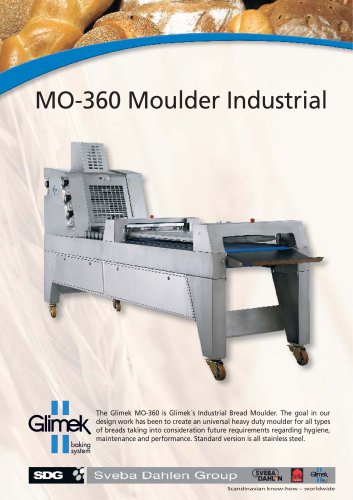

Glimek MO-360 Moulder

2 Pages

-

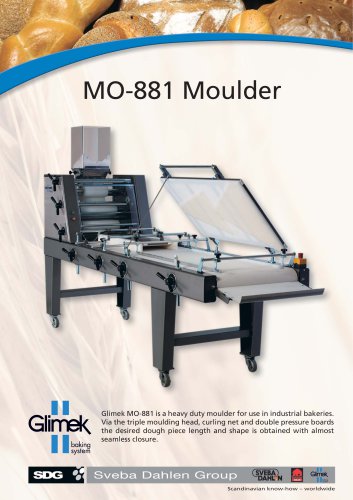

Glimek MO-881 Moulder

2 Pages

-

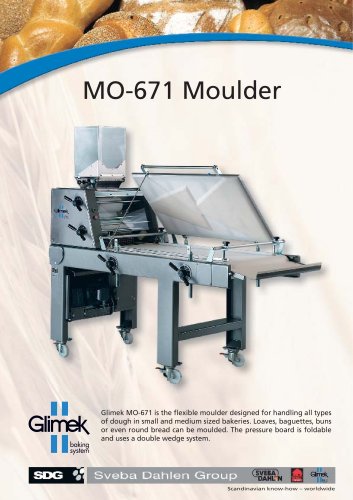

Glimek MO-671 Moulder

2 Pages

-

Glimek SD-600 Dough Divider

2 Pages

-

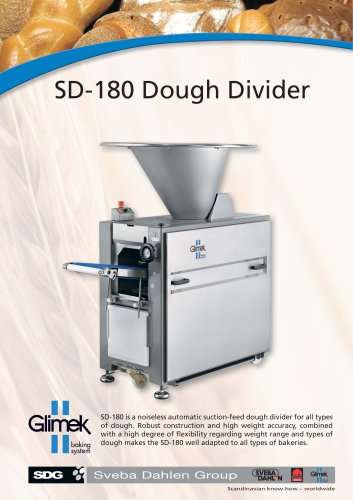

Glimek SD-180 Dough Divider

2 Pages

-

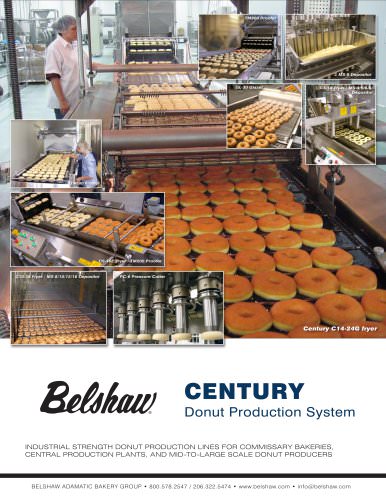

Century System Brochure

6 Pages

-

Donut Robot® Mark VI

4 Pages

-

Donut Robot® Mark V

4 Pages

-

Donut Robot® Mark II (Gas)

2 Pages

-

Type K Donut Depositor

9 Pages

-

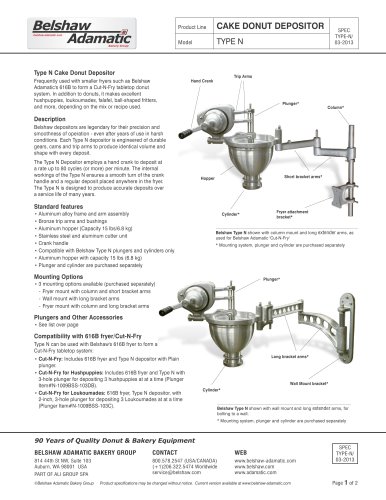

Type N Cake Donut Depositor

2 Pages

-

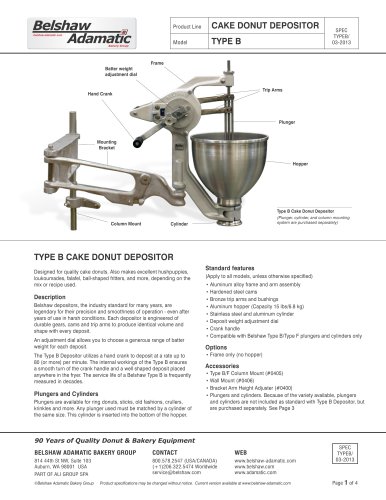

Type B Cake Donut Depositor

4 Pages

-

618L Donut Fryer (Electric)

2 Pages

-

616B Donut Fryer

2 Pages

-

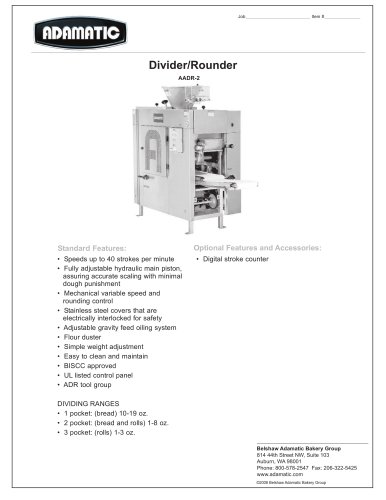

VDR Divider Rounder

2 Pages

-

NDR Divider Rounder

2 Pages

-

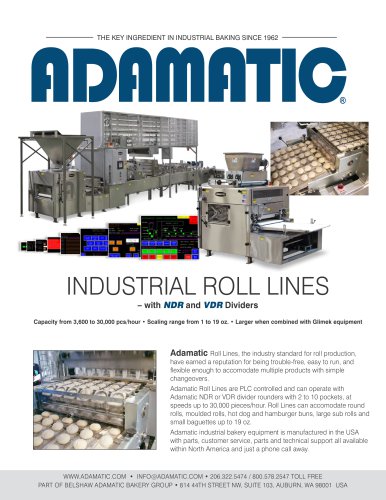

INDUSTRIAL ROLL LINES

3 Pages

-

The BX Eco-touch

4 Pages

-

ADR2 Divider Rounder

1 Pages

-

SD-300

2 Pages

-

MO-671

2 Pages

-

CR-360

2 Pages

-

Straight dough line

2 Pages

-

Multiple bread line

2 Pages

-

Flexible bread line

2 Pages

-

Eco bread line

2 Pages

-

Artisan bread line

2 Pages

Archived catalogs

-

AMDO-2W

2 Pages

-

BX3-E - BX4-E

6 Pages

-

AADR-2

2 Pages

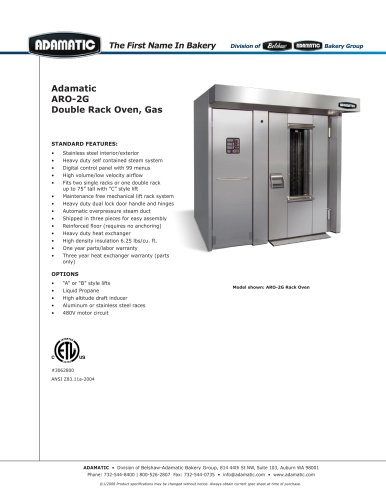

-

ARO-2G

2 Pages

-

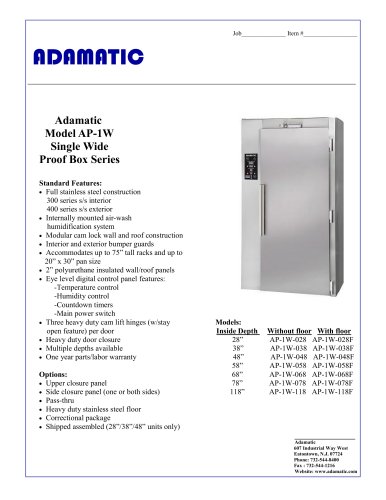

AP-1W

2 Pages

-

AMRO-G Series

2 Pages

-

USR01

2 Pages

-

AMRO-E series

2 Pages

-

Adamatic AP-2W

2 Pages

-

ADAMATIC Catalog

59 Pages

-

Supermarket/Retail brochure

4 Pages

-

Foodservice brochure

4 Pages

-

Wholesale brochure

4 Pages