Catalog excerpts

The No.1 Source for Donut Production Equipment Donut Robot Mark II • Mark II Gas • Mark V Automatic Donut Fryers A Donut Robot® is easier, more productive, more fun to use ~ and makes better quality donuts! EASIER. Just fill up the hopper with donut batter, and leave the machine to itself. There’s no standing over the fryer, no donut sticks and no turning or flipping. MORE PRODUCTIVE. With a Donut Robot®, no time is lost manually depositing donuts, or taking donuts out with screens. MORE FUN TO USE. Ask anyone who uses a Donut Robot® ~ the operator is free to do other jobs, while the machine is busy making donuts! MORE FUN TO WATCH. A Donut Robot® is less bulky than an open kettle fryer and is an irresistable attraction to customers and passers-by! BETTER QUALITY DONUTS. With a Donut Robot®, each donut is deposited at the right time, in the right place. Each donut is given the same amount of frying time and gently turned over at the same point. Because of the controlled conditions , donuts made on a Donut Robot® absorb up to 50% less shortening than they do in standard kettle fryers. ©02/2013 BELSHAW ADAMATIC BAKERY GROUP | 800.578.2547 +1.206.322.5474 | WWW.BELSHAW.COM | WWW.BELSHAW-ADAMATIC.COM | INFO@BELSHAW.COM

Open the catalog to page 1

Donut Robot Mark II •Mark V Donut Robot® Mark II & Mark V – How they work Donut Robot® Fryers deposit, fry, turn, and dispense cake donuts automatically, improving donut quality and reducing costs. Training and labor requirements are substantially reduced while high quality, consistent and repeatable donuts are produced time after time. Additionally, Donut Robot® fryers can reduce shortening use by up to 50% in comparison with kettle fryers. Donut Robot® fryers are fun to watch and always attract passers-by – improving foot traffic and impulse buys. Donut size, frying times and shortening...

Open the catalog to page 2

Donut Robot® Mark II & Mark V Specifications Mark II • Mark II Gas • Mark V (Standard Models) ▪▪ Automatic cake donut depositor, synchronized at all times with fryer conveyor ▪▪ Aluminum hopper with 10 lbs (4.5kg) batter capacity ▪▪ Plain donut plunger, stainless steel, 1-9/16" (39.7mm) diameter. ▪▪ Deposits 2 donuts per conveyor row. ▪▪ Batter weight adjustment dial, allows variation from small to large donuts ▪▪ Stainless steel fryer kettle, easily removable from fryer outer casing ▪▪ High durability, low wattage-density heating elements ▪▪ Temperature adjustment dial (Thermostat) ▪▪ High...

Open the catalog to page 3

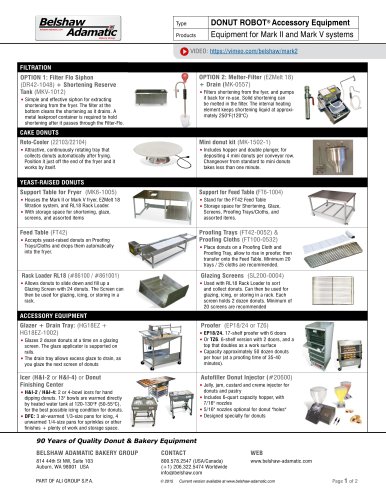

Donut Robot® Mark II & Mark V Accessories Basic options for Donut Robots® ▪▪ Extended drain with valve (Item# MK-0557) ▪▪ Mini donut conversion kit (Item#MK-1502-1). Kit includes hopper and double plunger, for depositing 4 mini donuts per conveyor row. Production rate for mini donuts is approximately 1400 mini donuts/hour at 60 seconds frying time. Changeover from standard to mini donuts and back again takes less than one minute ▪▪ Star plunger (Part Nbr: U1001S): the Star plunger makes a well-rounded center hole with a star pattern around it Drain & Valve • Mini Donut Conversion Kit • Star...

Open the catalog to page 4All ADAMATIC catalogs and technical brochures

-

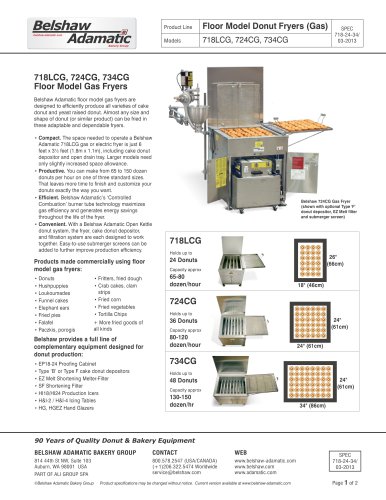

Belshaw 718L-724-734

2 Pages

-

Harmony Modular Deck

8 Pages

-

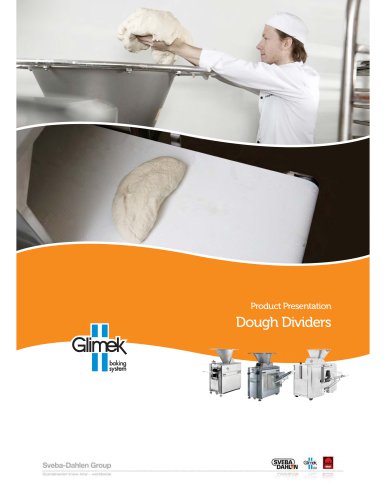

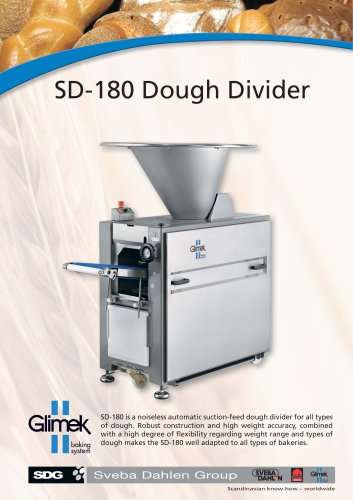

Dough Dividers

8 Pages

-

Moulders

8 Pages

-

BL Bowl Lift

2 Pages

-

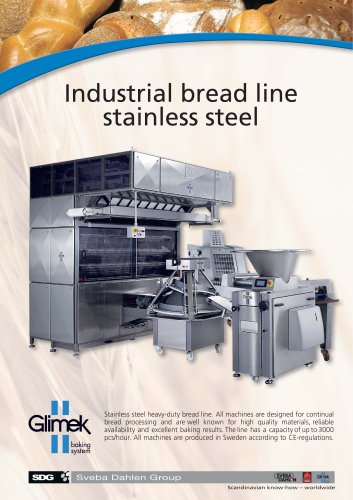

Bread Lines

12 Pages

-

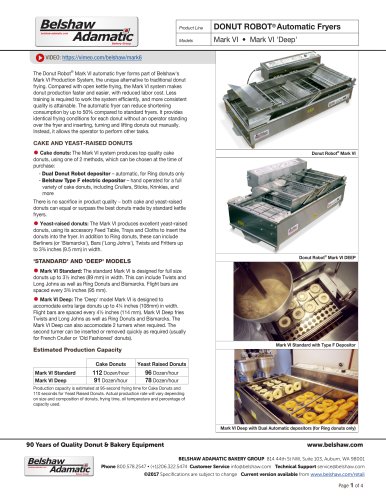

Mark VI ‘Deep’ System

2 Pages

-

TYPE K PANCAKE DISPENSER

2 Pages

-

Hushpuppy Depositor

2 Pages

-

Type F-YRD

2 Pages

-

Type F

2 Pages

-

PRF-2022

2 Pages

-

PRF-2021

2 Pages

-

OVEN-2010

2 Pages

-

DX Oven

2 Pages

-

OVEN 2020

4 Pages

-

Rack Loader

2 Pages

-

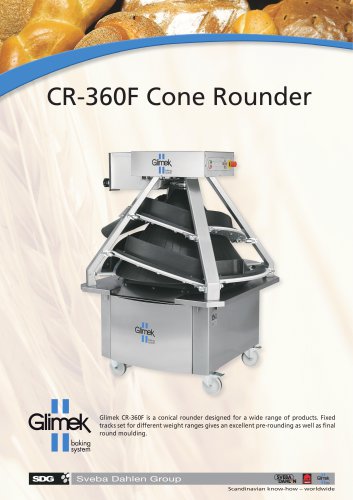

Glimek CR-360 Cone Rounder

2 Pages

-

Adamatic VDR Divider Rounder

2 Pages

-

Adamatic NDR Divider Rounder

2 Pages

-

Glimek Artisan Bread Line

2 Pages

-

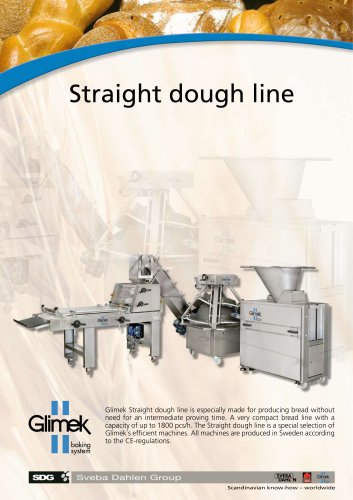

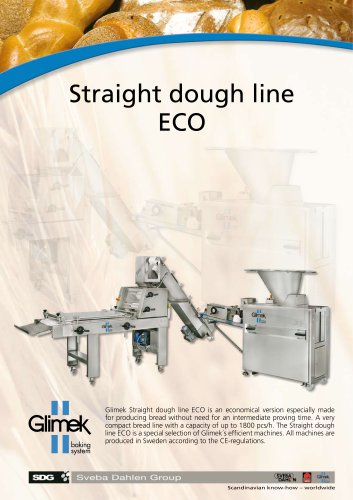

Glimek Straight Dough Line

2 Pages

-

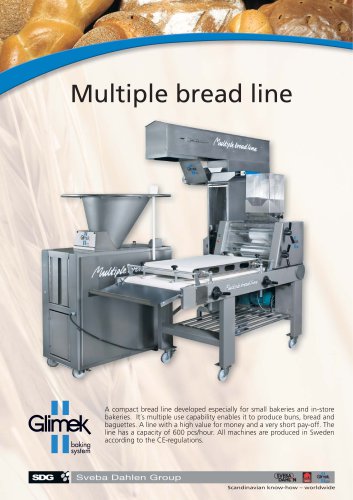

Glimek Multiple Bread Line

2 Pages

-

Glimek Eco-line

2 Pages

-

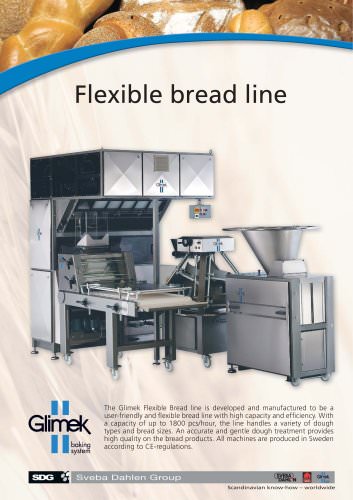

Glimek Flexible Bread Line

2 Pages

-

Glimek SD-300 Dough Divider

2 Pages

-

Glimek CR-360F Cone Rounder

2 Pages

-

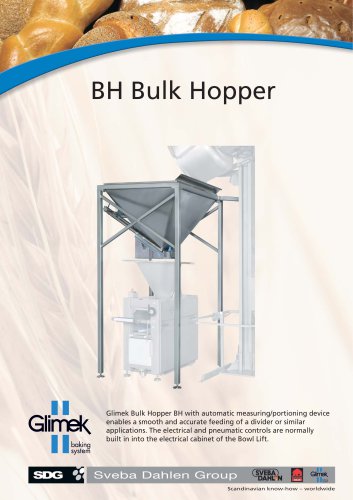

Glimek BH Bulk Hopper

2 Pages

-

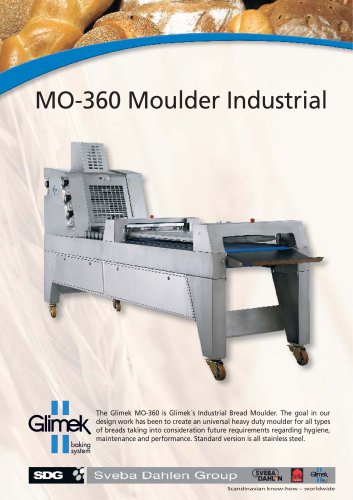

Glimek MO-360 Moulder

2 Pages

-

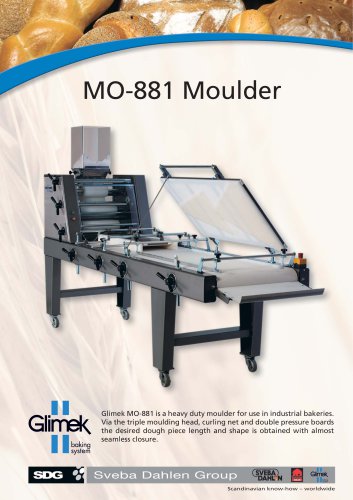

Glimek MO-881 Moulder

2 Pages

-

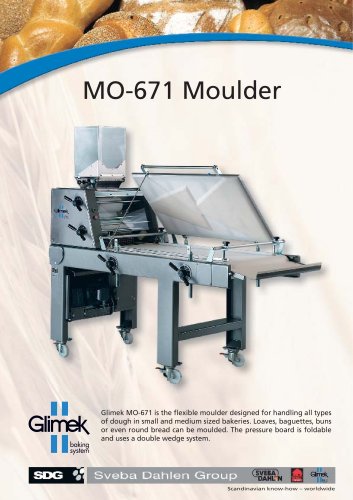

Glimek MO-671 Moulder

2 Pages

-

Glimek SD-600 Dough Divider

2 Pages

-

Glimek SD-180 Dough Divider

2 Pages

-

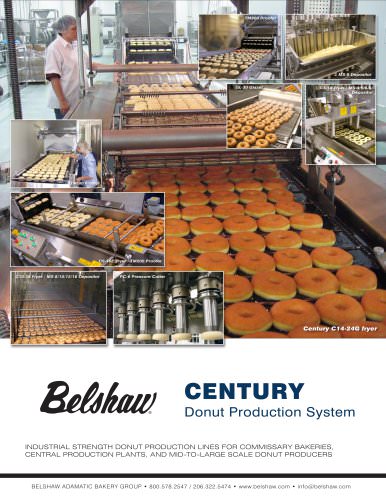

Century System Brochure

6 Pages

-

Donut Robot® Mark VI

4 Pages

-

Donut Robot® Mark II (Gas)

2 Pages

-

Type K Donut Depositor

9 Pages

-

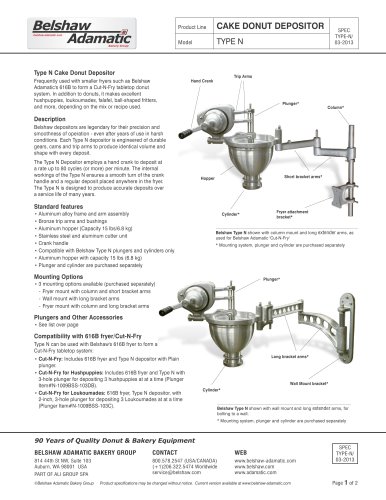

Type N Cake Donut Depositor

2 Pages

-

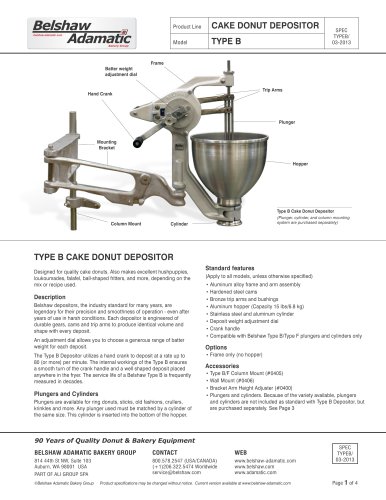

Type B Cake Donut Depositor

4 Pages

-

618L Donut Fryer (Electric)

2 Pages

-

616B Donut Fryer

2 Pages

-

VDR Divider Rounder

2 Pages

-

NDR Divider Rounder

2 Pages

-

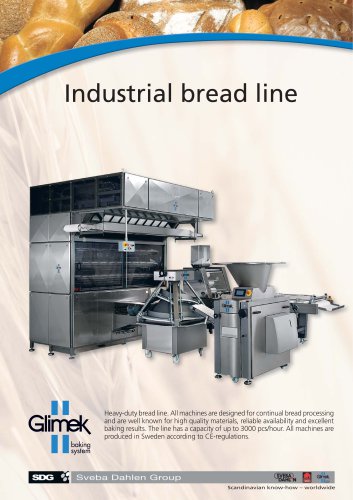

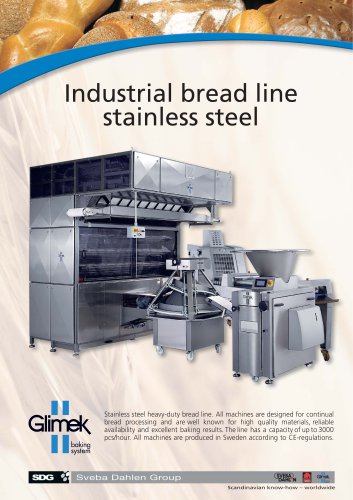

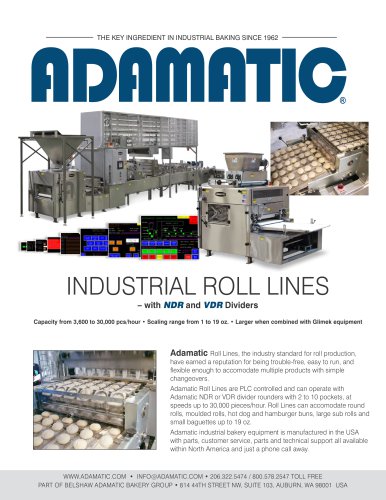

INDUSTRIAL ROLL LINES

3 Pages

-

The BX Eco-touch

4 Pages

-

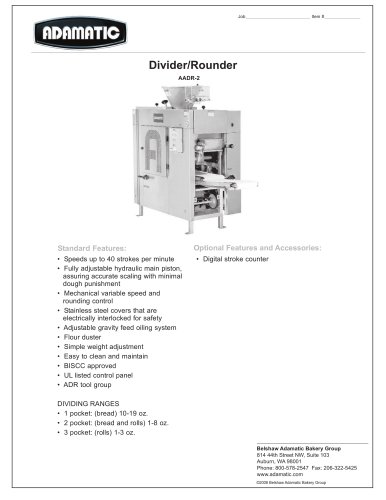

ADR2 Divider Rounder

1 Pages

-

SD-300

2 Pages

-

MO-671

2 Pages

-

CR-360

2 Pages

-

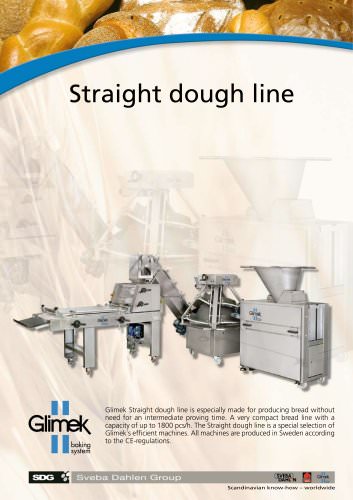

Straight dough line

2 Pages

-

Multiple bread line

2 Pages

-

Flexible bread line

2 Pages

-

Eco bread line

2 Pages

-

Artisan bread line

2 Pages

Archived catalogs

-

AMDO-2W

2 Pages

-

BX3-E - BX4-E

6 Pages

-

AADR-2

2 Pages

-

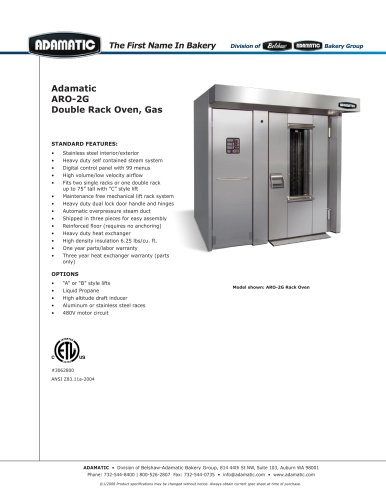

ARO-2G

2 Pages

-

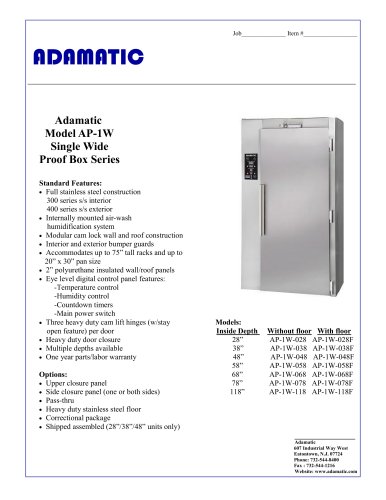

AP-1W

2 Pages

-

AMRO-G Series

2 Pages

-

USR01

2 Pages

-

AMRO-E series

2 Pages

-

Adamatic AP-2W

2 Pages

-

ADAMATIC Catalog

59 Pages

-

Supermarket/Retail brochure

4 Pages

-

Foodservice brochure

4 Pages

-

Wholesale brochure

4 Pages