Catalog excerpts

EN • 1 664Y4300 • G RU PL DE IT ES NL FR EN deltapro & pro pack Installation, operating and maintenance instructions

Open the catalog to page 1

664Y4300 • G EN • 2 RU PL DE IT ES NL FR EN INDEX Electrical connection 17 Electrical connection of the boiler 17 Optional controls 18 Installing a high or low temperature heating system with Control Unit 18 BMV oil burner features 20 Description of the BMV oil burner 20 BMV oil burner settings 20 BG 2000-S gas burner features 21 ACV BG 2000-S premix burner 21 BG 2000-S gas burner settings 21 Gas categories 22 Comm issioning and maintenance 24 Filling the hot water and heating circuits 24 Boiler commissioning 24 Recommendation 24 Boiler maintenance 24 Burner maintenance 24 Maintenance of...

Open the catalog to page 2

EN • 3 664Y4300 • G RU PL DE IT ES NL FR EN Who should read these instructions These instructions should be read by: - the design engineer/consultant - the user - the installer - the service engineer Symb ols Re comme ndations • Carefully read this manual before installing and bringing the boiler into service. • It is prohibited to modify the interior of the appliance in any way, without the manufacturer’s prior written agreement. • The boiler must be installed by a qualified engineer, in accordance with the applicable local standards and codes. • Failure to follow the instructions...

Open the catalog to page 3

664Y4300 • G EN • 4 RU PL DE IT ES NL FR EN WOR KING PRINCIPL E The Delta Pro boiler is a high performance hot water producer using indirect heat transfer due to its Tank-in-Tank technology. At the centre of the Delta Pro there is a stainless steel cylinder through which the flue tubes pass. It is surrounded by a mild steel shell containing the primary water (neutral fluid). The outer shell extends down to the combustion chamber and also surrounds the flue gas tubes. The heat exchange surface is therefore larger than that of traditional direct fired hot water boilers. The gas or oil burner...

Open the catalog to page 4

664Y4300 • G EN • 6 RU PL DE IT ES NL FR EN 2 5 1 4 3 6 US E OF TH E BOIL ER Please get your system serviced every year by a qualified technician. More frequent servicing may be required depending on boiler use. If this is the case, consult your installer for advice. Starting the burner: In normal operation, the burner starts automatically as soon as the boiler drops below the temperature setpoint. Before the boiler is serviced, switch off the electrical supply with the external isolator. Also switch the general switch on the control panel to “OFF”. HEATIN G CIRCUIT PR ESSUR E The heating...

Open the catalog to page 6

EN • 7 664Y4300 • G RU PL DE IT ES NL FR EN PUSH USER GUIDE OIL OR GAS BURN ER LOC KOUT The safety warning light on the burner indicates an operational fault. Wait five minutes and then reset the burner by pressing the “RESET” button on the burner. If the burner does not restart, call a technician after making sure that it is not a power cut or that the oil/gas is off. W ait until the boiler temperature is below 60 °C before switching on. If the problem persists, please contact your installer. Starting the burner: In normal operation, the burner starts automatically as soon as the boiler...

Open the catalog to page 7

664Y4300 • G EN • 8 RU PL DE IT ES NL FR EN 53 53 53 53 4x Ø 6,5 (M8) Ø 112 General The units are delivered fully assembled, tested and packed on a timber base with shockproof edges; the package is protected by a heat-shrunk plastic film. Upon receipt and after unpacking, check the equipment for transport damage. For transport purposes, refer to the dimensions and weights given below: Maximum operating conditions Maximum service pressure (tank full of water) - Heating circuit: 3 bar - Hot water circuit: 10 bar Test pressure (tank full of water) - Heating circuit: 4.5 bar - Hot water...

Open the catalog to page 8

EN • 9 664Y4300 • G RU PL DE IT ES NL FR EN A D K F G E B C H I L J A D F M G E B C H L J I Delta Pro 25/45/55 Delta Pro Pack 25/45 TECHNICAL CHARA CTERIST ICS Dime nsions A [mm] B [mm] C [mm] D [mm] E [mm] F [mm] Ø G [mm] H [mm] I [mm] J [mm] K [mm] L [mm] M [mm] Kg (*) Delta Pro 25 1760 540 584 1386 360 200 100 220 1445 1445 928 1400 — 145 Delta Pro 45 1760 540 584 1386 390 200 100 220 1445 1445 928 1400 — 168 Delta Pro 55 1760 540 584 1586 390 200 100 220 1645 1645 928 1600 — 200 Delta Pro Pack 25 1760 540 584 1386 360 63 100 220 1723 1445 — 1400 128 145 Delta Pro Pack 45 1760 540 584...

Open the catalog to page 9

664Y4300 • G EN • 10 RU PL DE IT ES NL FR EN Boiler room - The flue connection must be carried out in compliance with the standards in force, for example NBN D51-003, taking account of local energy supplier and fire regulations as well as regulations relating to “noise pollution”. - Make sure that all air vents are unobstructed. - Do not store flammable products in the boiler room. - Make sure that corrosive products, such as paint, solvents, chlorine, salt, soap and other cleaning products, are not stored near to the boiler. - The boiler must be placed on a non-combustible surface....

Open the catalog to page 10

EN • 11 664Y4300 • G RU PL DE IT ES NL FR EN Type of flue connection B23 : Connection to a flue with the combustion air taken directly in the boiler room. B23P : Connection to an exhaust system of the combustion products designed to operate with positive pressure. C13 : Connection by pipes with horizontal terminals that simultaneously take in combustion air for the burner and discharge combustion products outside through openings that are either concentric or close enough together to be subjected to similar wind conditions. C33 : Connection by pipes with vertical terminals that...

Open the catalog to page 11

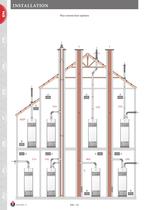

664Y4300 • G EN • 12 RU PL DE IT ES NL FR EN C83 C33 C43 C43 C13 B23 C53 B23P A B A A A B A B A A A C Install ation Flue connection options

Open the catalog to page 12

EN • 13 664Y4300 • G RU PL DE IT ES NL FR EN A F D B C D E B 270 295 255 540 C13 C33 240 630 190 Install ation A terminals Code Item SIZE 537D6197 Vertical terminal 1515 mm 537D6198 Horizontal terminal with wall plates 795 mm B duc ts Code Item SIZE 537D6199 Length 250 mm 210 mm 537D6200 Length 500 mm 460 mm 537D6201 Length 1000 mm 960 mm C adjus table duc t Code Item 537D6202 Length adjustable from 325 to 400 D pipe be nds Code Item 537D6203 43°-45° bend 537D6204 87°-90° bend E Conde nsa tion measu ring and collec tion de vice Code Item SIZE 537D6226 Condensate collector and measuring tube...

Open the catalog to page 13All ACV catalogs and technical brochures

-

PRODUCTS OVERVIEW 2019

28 Pages

-

E-TECH

7 Pages

-

LARGE CAPACITY TANKS

4 Pages

-

COMPACT CONDENS

2 Pages

-

WATERMASTER

2 Pages

-

Smart Line & SLEW

2 Pages

-

Smart ME

2 Pages

-

Heliosplan S

52 Pages

-

ACV products 2014

20 Pages

-

Comfort

4 Pages

-

Room Thermostat

2 Pages

-

HeatMaster

2 Pages

-

Mini Brochure

26 Pages

-

Product Overview 2013

20 Pages

Archived catalogs

-

SolarMaster

16 Pages

-

etech p

27 Pages

-

alfaF - FV

2 Pages

-

PUFFER – S1

12 Pages

-

Compact A

18 Pages

-

alfa

2 Pages

-

Mini-catalog ACV 2007

10 Pages