Catalog excerpts

Uniclass L7315 CI/SfB January 2012 (52.6) ACO Building Drainage Gully Systems Product catalogue ACO Stainless Steel Gully Systems - Handbook for Specifiers, Installers and Contractors

Open the catalog to page 1

ACO Building Drainage ACO Building Drainage Our built environment is becoming ever more Our global resources and fabrication capacity ACO Building Drainage is a division of ACO complex. Applications are becoming more make it possible for us to deliver best value, Technologies plc and part of the worldwide sophisticated and the increasing pressure of both with our standard products and with our ACO Group. The Group has sales in excess of regulations and standards make achieving bespoke designs. Confidence is further £600 million worldwide with production design, performance and financial...

Open the catalog to page 2

ACO Stainless Steel Gully Systems Contents General introduction ACO Building Drainage gullies 4 Load class 6 Standards and accreditations 7 Fixed height and telescopic gullies by family range 157 (EG200 & EG250), 218 (EG300), 357 (EG400) Systems overview 8 Characteristics and benefits 11 Gully guide 14 Technical data and order information 17 Installation guide 33 EG150 Eurogullies System overview 36 Characteristics and benefits 37 Technical data and order information 38 Installation guide 42 Rodding eyes System overview 43 Characteristics and benefits 43 Technical data and order information...

Open the catalog to page 3

ACO Stainless Steel Cully Systems ACO Building Drainage gullies ACO Building Drainage gullies represent the accumulation of many years practica experience and design know-how in stainless steel fabrication technologies. All the systems featured here are manufactured in austenitic stainless stee grades 304 or 316 and are fully pickle passivated in order to ensure corrosion free product. Their design includes smooth bowl shaped structures to minimise possible siltation, and all include an integral foul The five systems present the designer and nstaller with literally hundreds of 'off the...

Open the catalog to page 4

General Introduction EC150 Eurogully range - Page 36 Typical applications: ■ Horizontal or vertical spigot outlet stainless steel ■ Designed for cementitious and resin screed, ceramic tile and vinyl sheet floor ■ Damp proof membrane bonding flange ■ Up to three back inlets Rodding Eyes - Page 43 Typical applications: ■ Brewing, bottling and canning plants ■ Double sealed rodding point with solid ■ Mainly for light duty applications ■ Stainless steel grade 304 pickle passivated with EPDM double seal ■ Vertical 0110mm spigot outlet Micro Floor gully - Page 46 Typical applications: ■ Shallow...

Open the catalog to page 5

ACO Stainless Steel Cully Systems Load class ACO Building Drainage consciously decided to develop the ACO Stainless Steel Gully system to conform to appropriate European standards in order to provide the specifier with confidence to specify products that will offer known reliable performance criteria. The gully system has been tested in

Open the catalog to page 6

General Introduction Standards and accreditations Hygienic standards In order to maintain a clean and sustainable hygienic environment, it is essential that Hygiene risk according to BS EN 1672 and BS EN ISO 14159 Acceptable according to BS EN 1672 and BS EN ISO 14159 drainage elements should be designed and manufactured to rigorous standards to ensure bacteria and pathogen traps are minimised. All ACO gullies are designed for optimum hygiene performance taking into account Not drainable design Drainable design guidelines described in BS EN 1672 and BS EN ISO 14159 to minimise hygiene risk....

Open the catalog to page 7

ACO Stainless Steel Gully Systems System overview - 157 (EG200 & EG250) and 218 (EG300) fixed height and telescopic ACO Building Drainage gully ranges 157 and available in a number of versions featuring Fixed height gullies are convenient, free- 218 are further developments of our highly different flow rates, grating designs, sizes and standing units suitable for cementitious, resin successful current ranges EG200/EG250 spigot outlet diameters to suit various or tiled floors. Telescopic gullies can be and EG300. applications. The floor construction and installed either with ACO gully tops...

Open the catalog to page 8

Fixed height and telescopic gullies by family range 157, 218 and 357 Silt baskets Gully tops Raising pieces Gully bodies for fixed height Gully bodies for telescopic adjustable gullies Adheshive bonding flange gully bodies ■ welding or adheshive bonding of waterproof membrane Clamping flange gully bodies mechanical clamping of waterproof membrane

Open the catalog to page 9

ACO Stainless Steel Gully Systems System overview - 357 (EG400) fixed height 1 2 10 3 4 Foul air traps 4 2 Silt baskets 3 1 Gratings Gully bodies

Open the catalog to page 10

Fixed height and telescopic gullies by family range 157, 218 and 357 Fixed height gullies Telescopic gullies Fixed gully height No seepage drainage facility With location flange ■ Friction lock height adjustment ■ No waterproof membrane connection With adhesive bonding flange ■ Friction lock height adjustment ■ Adhesive bonding flange for waterproofing layer ■ Seepage drainage or sealed solution easily configured on installation With mechanical clamping flange ■ Friction lock height adjustment ■ Mechanical clamping flange for waterproofing layer ■ Seepage drainage or sealed solution easily...

Open the catalog to page 11

ACO Stainless Steel Gully Systems Characteristics and benefits Features and benefits ACO gully features & benefits: 1 10 Edge in-fill significantly improves hygiene and durability 2 Large radii for easy cleaning 3 Deep-drawn body ensures smooth contours eliminating crevices 4 2 1 3 4 5 Friction ring reduces installation time 5 1 Friction ring easily convertible for 9 membrane drainage 9 6 Foul air trap design minimises 6 6 evaporation rate and aerosol mobility 7 Dry sump design, no water retention in 7 7 8 8 sump 8 Gully flow rate and self-cleansing exceeds requirements of BS EN 1253 9...

Open the catalog to page 12

Fixed height and telescopic gullies by family range 157, 218 and 357 Specifier benefits ■ Hygienic design following BS EN 1672 ■ Stainless steel construction for durability ■ Gully top edge infill supplied as standard ■ Wide range of gratings for all load class ■ Slip resistant gratings available for added user safety ■ Reliable waterproofing membrane connection options ■ Waterproofing membrane seepage drainage provision ■ Suitable for all floor types including vinyl Contractor benefits ■ Friction lock telescopic adjustment reduces installation time ■ Gully levelling facilities ■ Quick and...

Open the catalog to page 13All ACO Building Drainage catalogs and technical brochures

-

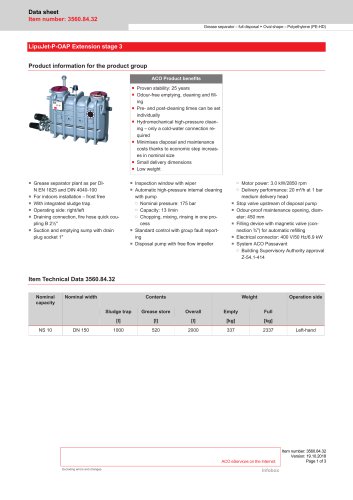

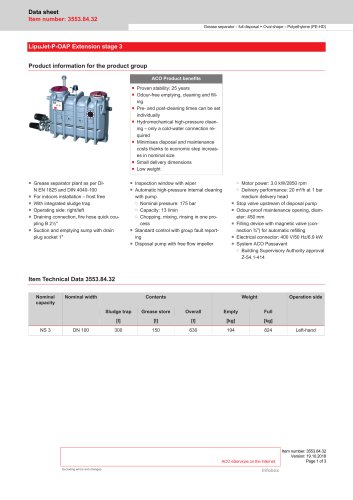

LipuJet-P-OAP 3830.85.32

3 Pages

-

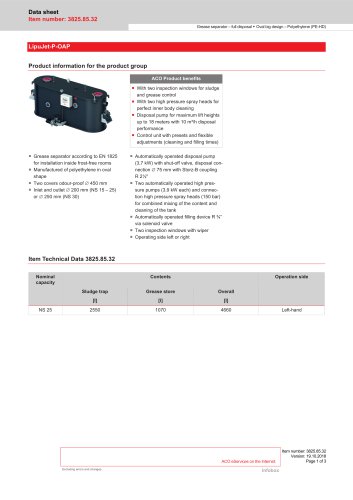

LipuJet-P-OAP 3825.85.32

3 Pages

-

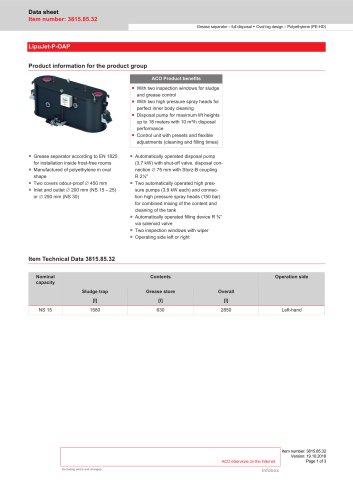

LipuJet-P-OAP

3 Pages

-

LipuJet-P-OAP 3815.85.32

3 Pages

-

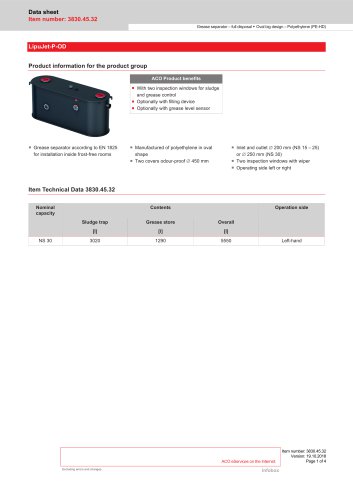

LipuJet-P-OD 3830.45.32

4 Pages

-

LipuJet-P-OD 3825.45.32

4 Pages

-

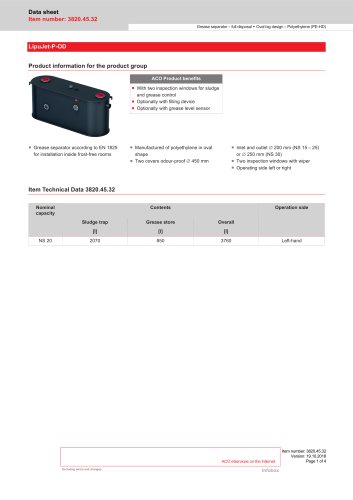

LipuJet-P-OD 3820.45.32

4 Pages

-

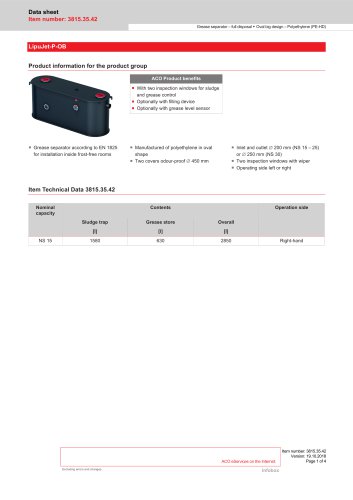

LipuJet-P-OD 3815.45.32

4 Pages

-

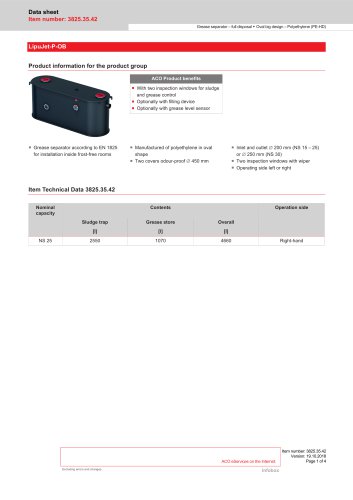

LipuJet-P-OB 3830.35.42

4 Pages

-

LipuJet-P-OB 3825.35.42

4 Pages

-

LipuJet-P-OB 3820.35.42

4 Pages

-

LipuJet-P-OB 3815.35.42

4 Pages

-

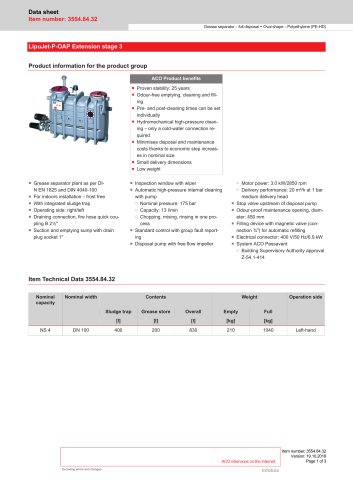

LipuJet-P-OAP 3560.84.32

3 Pages

-

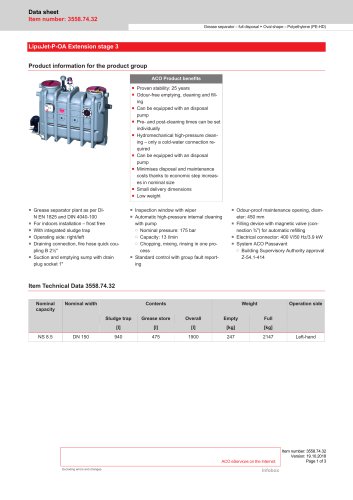

LipuJet-P-OAP 3558.84.32

3 Pages

-

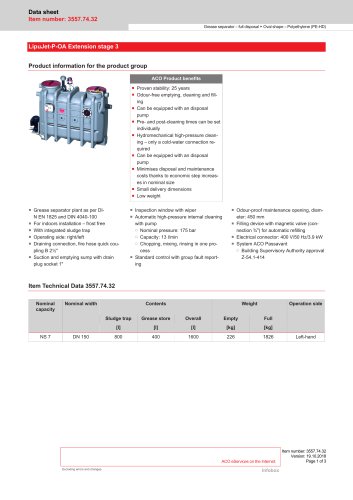

LipuJet-P-OAP 3557.84.32

3 Pages

-

LipuJet-P-OAP 3555.84.32

3 Pages

-

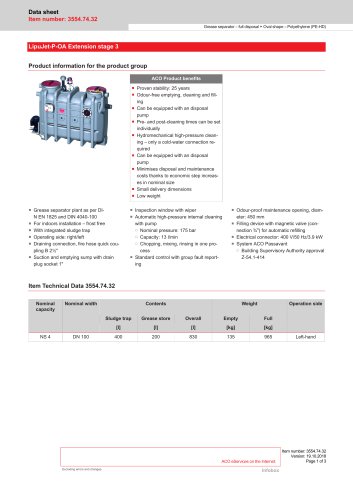

LipuJet-P-OAP 3554.84.32

3 Pages

-

LipuJet-P-OAP 3553.84.32

3 Pages

-

LipuJet-P-OAP 3552.84.32

3 Pages

-

LipuJet-P-OAP 3551.84.32

3 Pages

-

LipuJet-P-OA 3560.74.32

3 Pages

-

LipuJet-P-OA 3558.74.32

3 Pages

-

LipuJet-P-OA 3557.74.32

3 Pages

-

LipuJet-P-OA 3554.74.32

3 Pages

-

LipuJet-P-OA 3553.74.32

3 Pages

-

LipuJet-P-OA 3552.74.32

3 Pages

-

LipuJet-P-OA 3551.74.32

3 Pages

-

LipuJet-P-OB 3560.34.00

3 Pages

-

LipuJet-P-OB 3558.34.00

3 Pages

-

LipuJet-P-OB 3557.34.00

3 Pages

-

LipuJet-P-OB 3555.34.00

3 Pages

-

LipuJet-P-OB 3554.34.00

3 Pages

-

LipuJet-P-OB 3553.34.00

3 Pages

-

LipuJet-P-OB 3552.34.00

3 Pages

-

LipuJet-P-OB 3551.34.00

3 Pages

-

Lipumax P-D Intermedi

52 Pages

-

Lipumax P-DM High Manual Co

52 Pages

-

Lipumax P-B Basic

52 Pages

-

Pipe®

36 Pages

-

AS2001 Tray Channel

20 Pages

-

Rainwater Outlets

32 Pages

-

Mobile separators

4 Pages

-

Junior® Backflow

2 Pages

-

Quatrix® without Chamber

2 Pages

-

uatrix® with Chamber

2 Pages

-

riplex® with Chamber

2 Pages

-

AS701 Upstand

2 Pages

-

AS801 Micro Channel

2 Pages

-

AS901 Hi Load

2 Pages

-

Shower Gratings

2 Pages

-

BD June Event Summary Binder

185 Pages

-

Railway Brochure

20 Pages

-

Biological Grease Traps

28 Pages

-

Grease Separators

52 Pages

-

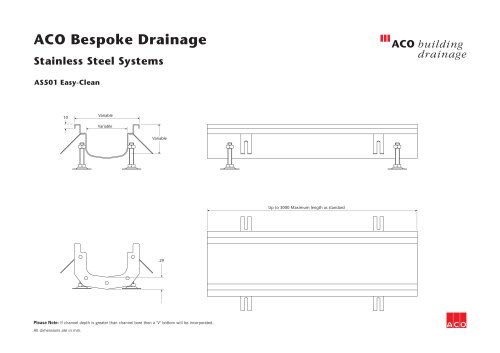

AS501

2 Pages

-

AS401

2 Pages

-

AS301

2 Pages

-

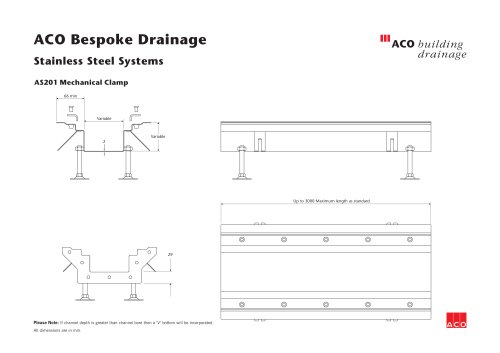

AS201

2 Pages

-

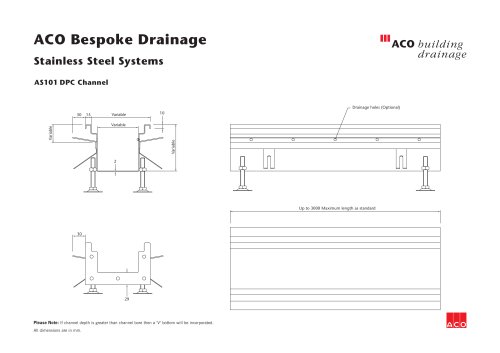

AS101

2 Pages

-

Radius Channel

2 Pages

-

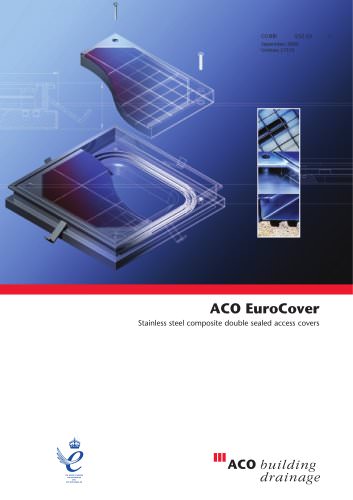

Eurocover Access Cover

8 Pages

-

Alucover Access Cover

2 Pages

-

FreeDeck

20 Pages

-

Pipe®

60 Pages

-

Bath-to-Wetroom Adaptor

2 Pages

-

Walk-in Solution

18 Pages

-

Easyflow

16 Pages

-

Shower Gullies

35 Pages

-

Shower Channels

48 Pages

-

Wetroom Former

2 Pages