Catalog excerpts

ACO Product catalogue ACO GM-X and GM-X-VACplus drain pipes and steel fittings for building drainage applications

Open the catalog to page 1

GM-X Steel drain pipes and fittings DN 40 - DN 250 and EN 1123 ACO Industries as a member of the international ACO Group of companies with more than 3200 employees worldwide is now presenting new galvanized and coated steel pipe product ranges GM-X and GM-X-VAC for gravity and syphonic drainage. Thanks to on-going development in this field, ACO offers today a wide range of standard pipes and all necessary fittings for building drainage applications. There are specially trained product managers available for you in the product manage- ment department, who are ready to answer all your...

Open the catalog to page 2

Material Drain pipes and fittings are manufactured from welded, one-time cold-drawn precision steel pipe in accordance with DIN 2394. Tensile strength: Rm 310-410 N/mm2 As a material, steel is distinguished by its good technological properties: • unbreakable • dimensionally stable • heat and frost proof • favourable acoustic behaviour • non-combustible Thermal expansion Expansion of various pipe materials With steel, thermal expansion is exceptionally limited. When a 1 metre piece of pipe is heated by 100°C, the length increase is 1.1 mm. The thermal expansion produced by the introduction...

Open the catalog to page 3

The GM-X Socket The GM-X socket is a two-stage design. The seal is retained by the first socket stage. The second stage centre the inserted pipe. The socket shape construction enables a solid, buckle-proof and rigid connection of pipes and mouldings to be made, and thus guarantees great tightness between the pipe and the socket, without the risk of the seal being compressed by its own or an outside load. GM-X Seal The GM-X seal is in the shape of a lip collar. It is inserted into the upper socket chamber. As a result of the other pipe end being pushed in, the sealing lips are forced against...

Open the catalog to page 4

The vacuum connection The vacuum installation with x-socket and GM-X-VACplus sealing element, corresponds to installations of the standard GMX sealing element. In contrast to the aforementioned installation the GM-X-VACplus sealing element fills both socket stages. Therefore guaranteeing a trouble-free vacuum operation. The seal-tight value of the vacuum seal joint complies with DIN 86 281. GM-X-VACplus seal The GM-X-VACplus sealing element allows the vacuum installations with „standard socket Type A1“. The seal is manufactured from EPDM and is provided with two flexible lip sealing...

Open the catalog to page 5

Corrosion proofing All pipes and fittings are hot galvanized inside and out. The zinc coating is on average 400 g/m2 or 56 µ. It is impact-resistant and shock-proof. The zinc coating produces a cathodic protection of the cut edges thus preventing bottom rust. In addition, the insides of the pipes and fittings are given an alkyd-melamine resin based plastic coating. Due to this internal coating of the pipes, frictional resistance on the internal surfaces is reduced and incrustation largely prevented. Together with the zinc coating, optimum corrosion protection is achieved. Both the hot...

Open the catalog to page 6

Making the socket joint for GM-X sockets 1. The seal is placed obliquely on the lower edge of the socket chamber. 2. Using your forefinger to press the seal to one side, push it into the socket chamber. 3. On releasing, the seal should pop into the socket chamber. (Adjust where necessary) Note: The outside seal edge collar must rest on the socket rim. 4. The seal is coated all-over inside with GM-X lubricant Undoing the socket joint The insertion pipe is heated around the socket with a heat source until the pipe can be pulled out of the socket. When reassembling, the seal must be changed....

Open the catalog to page 7

Test information Production monitoring Quality management In accordance with the amended German Federal States’ conformity regulations (PrüfzVO), steel drain pipes and fittings as per DIN EN 1123 are exempt from the construction supervision requirement for official approval. However, the components are still subject to being monitored by an authorized testing body. GM-X drain pipes and fittings are subject to production monitoring by the Bavarian Institute for Technical Building Equipment and Domestic Water Supplies, Würzburg branch. GM-X drain pipes and fittings are subject to production...

Open the catalog to page 8

Delivery range overview Double sockets page 19 [ | |j with long socket page 30 Pipe clips Drain plugs Angle bends short socket Pipe bridges socket caps page 13 bend with normal ■^TTJ Tank fittings CM-X [ETTU Forked T pieces with calming Wall closet CM-X I Securing clips bends 90° for ver- page 32 Securing clamps tical mounting Angle bends Single branches Concentric tran- sition pipes Transition pipes double branches changing from other pipe types Transition bran- Socket flange Spigot flange

Open the catalog to page 9

Socket dimensions For pipes and fittings with 2 sockets both sockets are the same design Special nominal widths for GM-X WC connections and prefabrication 110 GM-X Plug-in connection Socket DN 40-200 with seal Socket DN 250 with set of seal GM-X -VACplus Plug-in connection Socket DN 40-70 with seal

Open the catalog to page 10

Pipes GM-X drain pipes with one socket 1 A in acc. to EN 1123 form B1 Order No. 040 050 070 080 100 125 150 200 250 GM-X drain pipes with two sockets 1 A in acc. to EN 1123 form B2 Order No. 040 050 070 100 125 150 200 Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system

Open the catalog to page 11

in acc. to bends with small radius 305 381 Bends with small radius in acc. to EN 1123 form C2 Order No. *040 *050 *070 *080 Bends with small radius in acc. to EN 1123 form C2 Order No. *Attention We would like to bring your attention to the fact, that all shaped components with the bend share varies due to production-engineering reasons. The design data are available at any time, if needed. Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system

Open the catalog to page 12All ACO Building Drainage catalogs and technical brochures

-

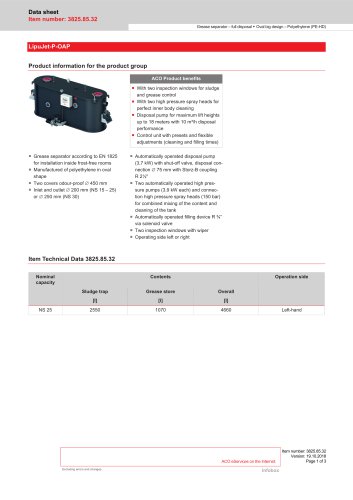

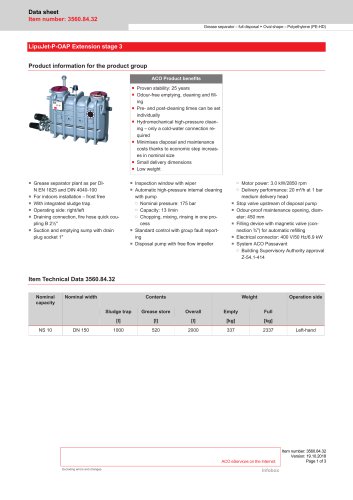

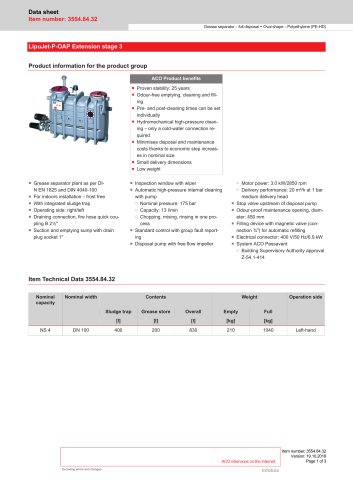

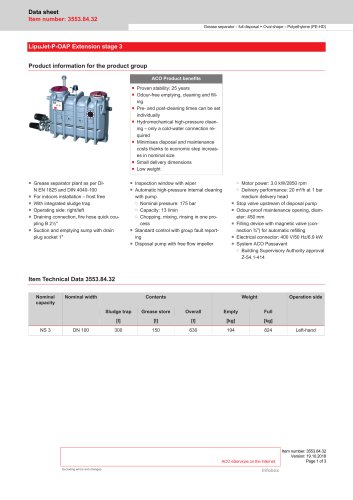

LipuJet-P-OAP 3830.85.32

3 Pages

-

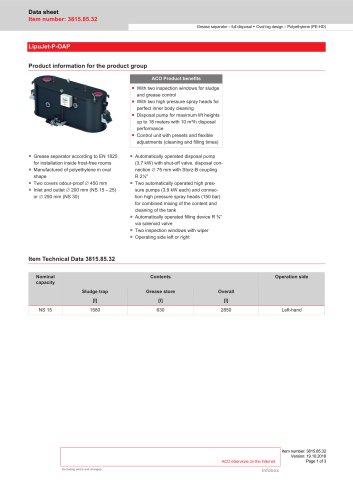

LipuJet-P-OAP 3825.85.32

3 Pages

-

LipuJet-P-OAP

3 Pages

-

LipuJet-P-OAP 3815.85.32

3 Pages

-

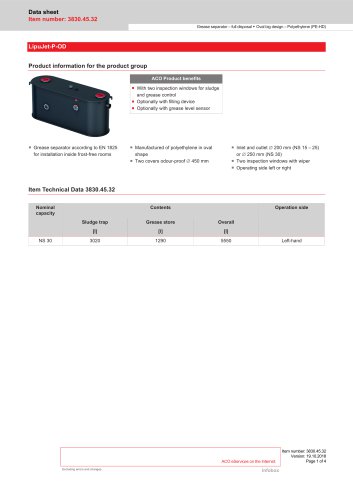

LipuJet-P-OD 3830.45.32

4 Pages

-

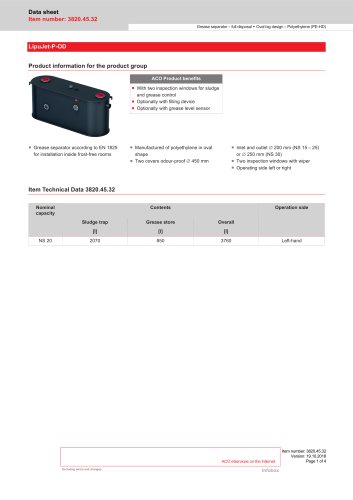

LipuJet-P-OD 3825.45.32

4 Pages

-

LipuJet-P-OD 3820.45.32

4 Pages

-

LipuJet-P-OD 3815.45.32

4 Pages

-

LipuJet-P-OB 3830.35.42

4 Pages

-

LipuJet-P-OB 3825.35.42

4 Pages

-

LipuJet-P-OB 3820.35.42

4 Pages

-

LipuJet-P-OB 3815.35.42

4 Pages

-

LipuJet-P-OAP 3560.84.32

3 Pages

-

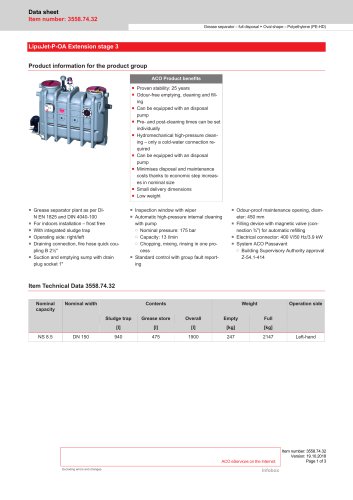

LipuJet-P-OAP 3558.84.32

3 Pages

-

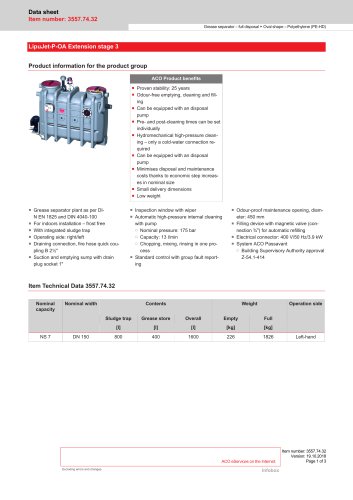

LipuJet-P-OAP 3557.84.32

3 Pages

-

LipuJet-P-OAP 3555.84.32

3 Pages

-

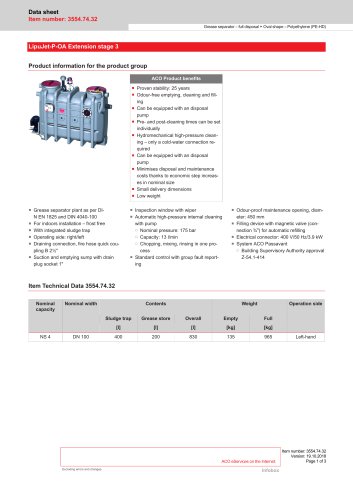

LipuJet-P-OAP 3554.84.32

3 Pages

-

LipuJet-P-OAP 3553.84.32

3 Pages

-

LipuJet-P-OAP 3552.84.32

3 Pages

-

LipuJet-P-OAP 3551.84.32

3 Pages

-

LipuJet-P-OA 3560.74.32

3 Pages

-

LipuJet-P-OA 3558.74.32

3 Pages

-

LipuJet-P-OA 3557.74.32

3 Pages

-

LipuJet-P-OA 3554.74.32

3 Pages

-

LipuJet-P-OA 3553.74.32

3 Pages

-

LipuJet-P-OA 3552.74.32

3 Pages

-

LipuJet-P-OA 3551.74.32

3 Pages

-

LipuJet-P-OB 3560.34.00

3 Pages

-

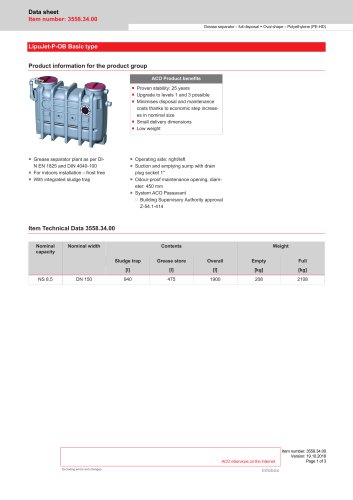

LipuJet-P-OB 3558.34.00

3 Pages

-

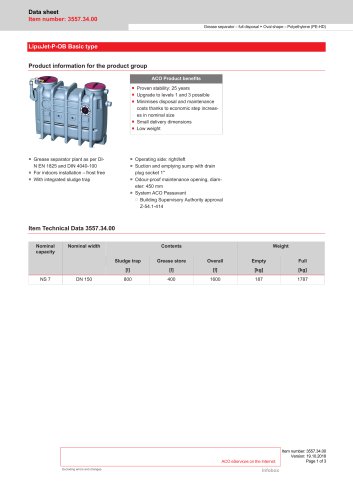

LipuJet-P-OB 3557.34.00

3 Pages

-

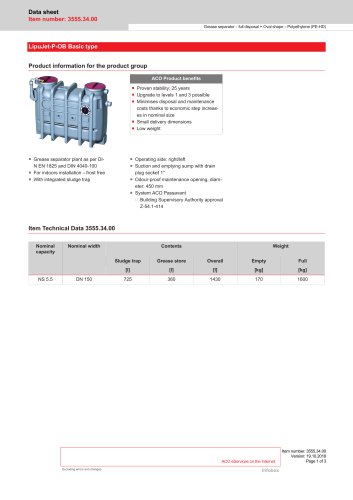

LipuJet-P-OB 3555.34.00

3 Pages

-

LipuJet-P-OB 3554.34.00

3 Pages

-

LipuJet-P-OB 3553.34.00

3 Pages

-

LipuJet-P-OB 3552.34.00

3 Pages

-

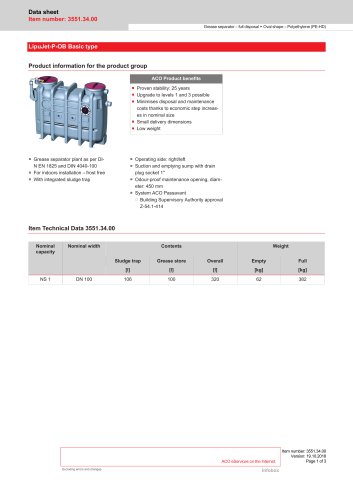

LipuJet-P-OB 3551.34.00

3 Pages

-

Lipumax P-D Intermedi

52 Pages

-

Lipumax P-DM High Manual Co

52 Pages

-

Lipumax P-B Basic

52 Pages

-

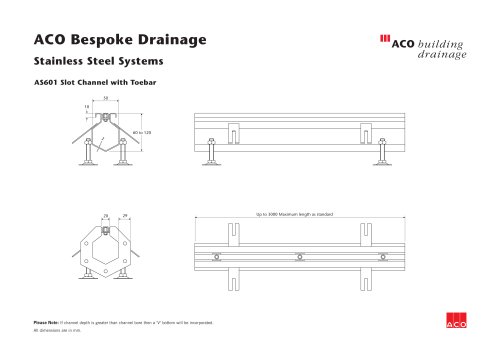

AS2001 Tray Channel

20 Pages

-

Rainwater Outlets

32 Pages

-

Mobile separators

4 Pages

-

Junior® Backflow

2 Pages

-

Quatrix® without Chamber

2 Pages

-

uatrix® with Chamber

2 Pages

-

riplex® with Chamber

2 Pages

-

AS701 Upstand

2 Pages

-

AS801 Micro Channel

2 Pages

-

AS901 Hi Load

2 Pages

-

Shower Gratings

2 Pages

-

BD June Event Summary Binder

185 Pages

-

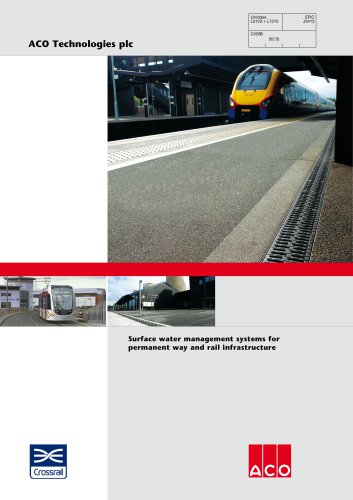

Railway Brochure

20 Pages

-

Biological Grease Traps

28 Pages

-

Grease Separators

52 Pages

-

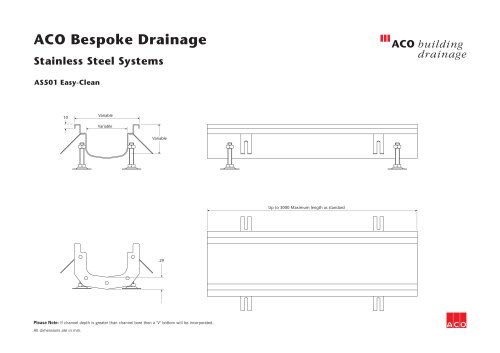

AS501

2 Pages

-

AS401

2 Pages

-

AS301

2 Pages

-

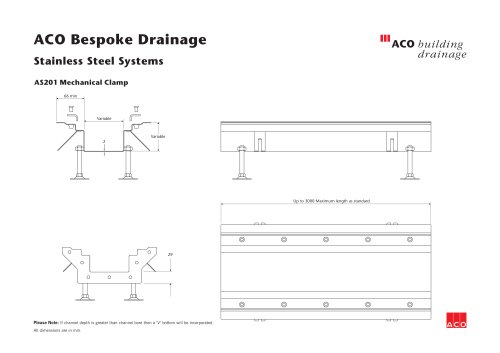

AS201

2 Pages

-

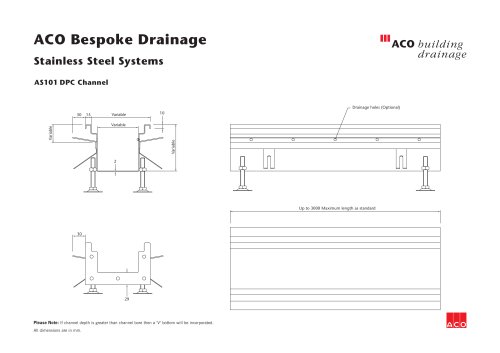

AS101

2 Pages

-

Radius Channel

2 Pages

-

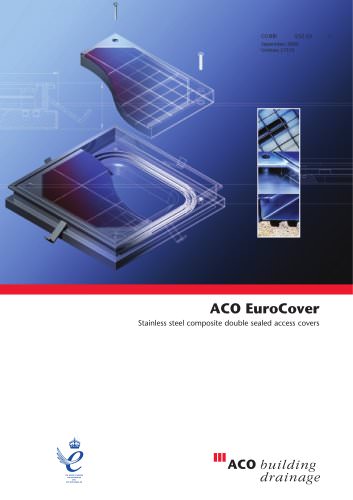

Eurocover Access Cover

8 Pages

-

Alucover Access Cover

2 Pages

-

FreeDeck

20 Pages

-

Pipe®

60 Pages

-

Stainless Steel Gully Systems

56 Pages

-

Bath-to-Wetroom Adaptor

2 Pages

-

Walk-in Solution

18 Pages

-

Easyflow

16 Pages

-

Shower Gullies

35 Pages

-

Shower Channels

48 Pages

-

Wetroom Former

2 Pages