Catalog excerpts

Product catalogue ACO Gravity Grease Separators

Open the catalog to page 1

Our built environment is becoming ever more complex. Applications are becoming more sophisticated and the increasing pressure of regulations and standards makes achieving design, performance and financial goals ever Enquiries Team: • A complete pricing service to stockists, contractors and clients. Tel: +44(0)1462 816666 Our mission: to eliminate design risk, to reduce installed and life cost and to deliver Email: abdestimating@aco.co.uk exceptional finish and performance in every product application. ACO Building Drainage • Product availability, delivery lead times, and Our global...

Open the catalog to page 2

ACO Gravity Grease Separators Contents The Need for Fat, Oil and Grease Management Local effects of fats, oils and grease (FOGs) Regional effects ACO Gravity Grease Separators When to use a Grease Management System Choosing a Grease Management System Separator Process Overview Selecting a Gravity Grease Separator ACO Below Ground Grease Separators ACO Lipumax P - Features and Benefits ACO Lipumax P - Product Range Overview ACO Lipumax P-B - Technical Data ACO Lipumax P-D Intermediate - Extension Stage 1 - Technical Data ACO Lipumax P-DM - High Extension Stage 2 - Technical Data ACO Lipumax...

Open the catalog to page 3

ACO Gravity Crease Separators The Need for Fat, Oil and Crease Management Local effects of fats, oils and grease (FOCs) One of the greatest drainage problems faced in kitchens and food processing areas is the accumulation of fats, oils and grease within the drainage system. Note: As FOGs cool in the drainage system they can solidify. If untreated, accumulation eventually leads to drainage system failure with potential health hazards within the food preparation area. Regional effects Drainage infrastructure blockage Reduced efficiency at sewage plant Watercourse pollution The problem of FOG...

Open the catalog to page 4

ACO Gravity Grease Separators When to use a Grease Management System FOGs and specified output quality Stable emulsions Vegetable and animal fats are separated through the Certain FOGs may form a stable emulsion, differential density mechanism in the separator, however, e.g. those created during dairy production some residual fats always remain in the output effluent. processes and are not suitable for treatment in Gravity Grease Separators. Regulatory authorities may require specific output quality and may test the installation for performance. Increasing levels of sophistication are...

Open the catalog to page 5

ACO Gravity Grease Separators Choosing a Grease Management System Compared with some European countries, the The lack of consistent, regulated control ACO Building Drainage offer a choice of UK has only recently addressed the problems means that demand, and therefore supply of grease management systems: a range of arising from fats, oils and grease through appropriate product has been limited, with biological or enzyme based traps, or national mechanisms such as the Building subsequent variability in the performance of separators based on differential density, often Regulations which now...

Open the catalog to page 6

ACO Gravity Grease Separators Separator Process Overview All ACO separators are designed to BS EN Maintenance options available 1825 Part 1 Grease Separators Principles of (according to separator type). Design, Performance and Testing, Marking and Quality Control. Pumped outlet connection using Bauer couplings Advanced high pressure (175 bar) cleaning system manual or automatic control Integrated disposal pump to assist vacuum disposal tanker Waste water from kitchens FOGs have a density less and food processing plants than water. Under the contains a mixture of water, correct conditions,...

Open the catalog to page 7

ACO Gravity Grease Separators Selecting a Gravity Grease Separator Stage 1 Consider waste water contents Although all separators accommodate silt, it is often necessary to remove course particles which might otherwise cause problems, for example fish waste, which will putrefy if allowed to enter the separator. Such waste can be removed by use of pre-strainer (e.g. see page 43). Note: Gravity Grease Separators are not designed to accommodate output from macerators. Stage 2 Establish separator size BS EN 1825 describes 3 methods of Sizing methods contained in this product catalogue cover the...

Open the catalog to page 8

ACO Gravity Grease Separators Step 2 - Select kitchen type (continued) Kitchen Type Typical kitchen characteristics Large catering establishment • Market fresh produce, large proportion of canned food • Few menus per day (1-2) • Prepared in few, large food containers Factory and office, canteens, student refectory • Kitchen ready, if applicable portioned out and pre-cooked/deep frozen food • Few menus • Prepared in large kitchens and/or microwave ovens • Large proportion of disposable crockery Step 3 - Calculate nominal size of Gravity Grease Separator Select kitchen type (See table in Step...

Open the catalog to page 9

ACO Gravity Grease Separators Stage 3 - Select separator location Fats, oils and grease generation Below ground installation Above ground installation ACO Lipumax Gravity Grease Separator for below ground installation ACO ECO-Jet Gravity Grease Separator for above ground installation Product information on pages 11 - 23 Product information on pages 27 - 43 ACO ECO-FPI Gravity Grease Separator for below ground installation ACO Hydrojet Gravity Grease Separator for above ground installation Product information on pages 24 - 26 Product information on pages 27 - 43

Open the catalog to page 10

ACO Below Ground Grease Separators ACO Lipumax P - Features and Benefits The ACO Lipumax range of below ground Using advanced design, materials and All ACO grease separators are manufactured, gravity grease separators are specifically manufacturing techniques, roto-moulding tested and certified in accordance with designed to provide not only efficient technology provides the below ground tanks separation performance of fats, oils and the structural integrity to withstand the individually hydraulically tested to ensure grease but also to ensure a durable and rigours of site handling and...

Open the catalog to page 11All ACO Building Drainage catalogs and technical brochures

-

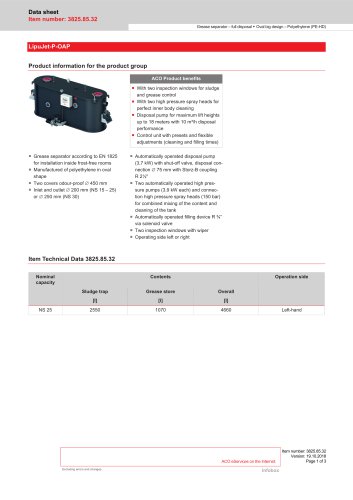

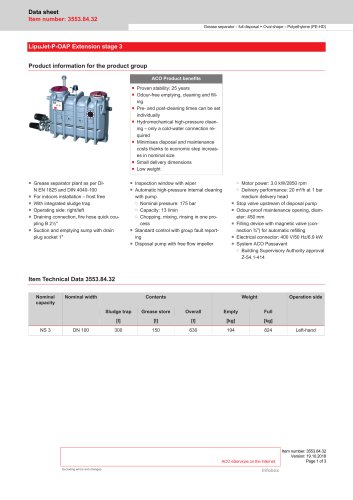

LipuJet-P-OAP 3830.85.32

3 Pages

-

LipuJet-P-OAP 3825.85.32

3 Pages

-

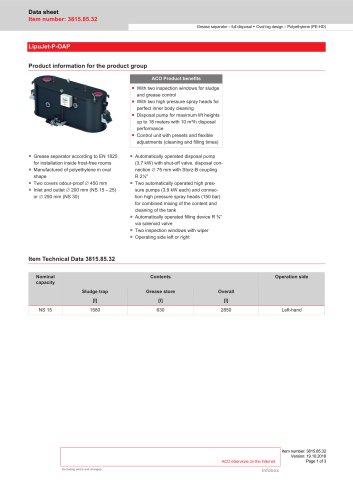

LipuJet-P-OAP

3 Pages

-

LipuJet-P-OAP 3815.85.32

3 Pages

-

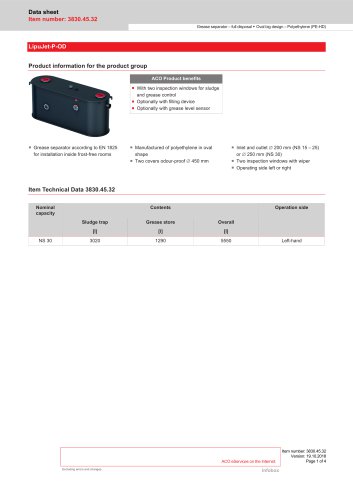

LipuJet-P-OD 3830.45.32

4 Pages

-

LipuJet-P-OD 3825.45.32

4 Pages

-

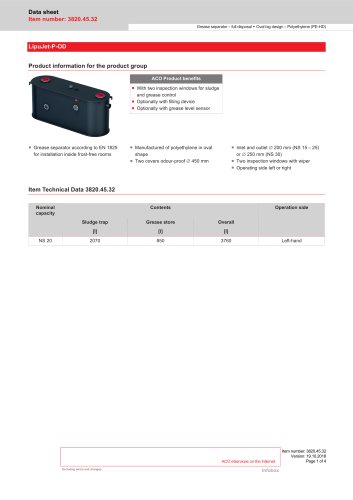

LipuJet-P-OD 3820.45.32

4 Pages

-

LipuJet-P-OD 3815.45.32

4 Pages

-

LipuJet-P-OB 3830.35.42

4 Pages

-

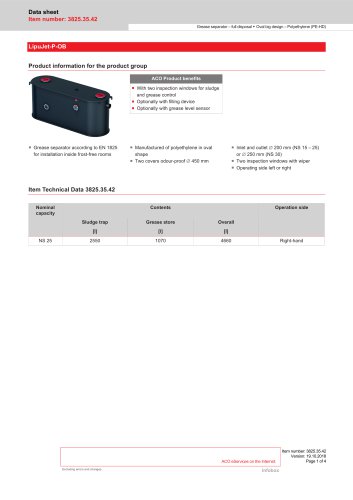

LipuJet-P-OB 3825.35.42

4 Pages

-

LipuJet-P-OB 3820.35.42

4 Pages

-

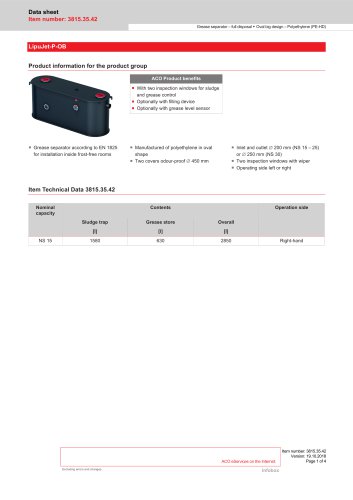

LipuJet-P-OB 3815.35.42

4 Pages

-

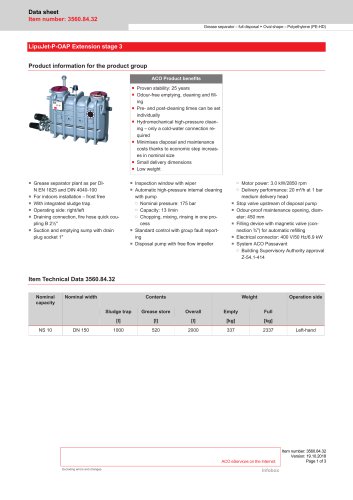

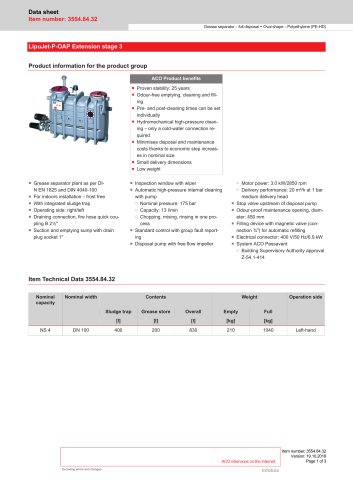

LipuJet-P-OAP 3560.84.32

3 Pages

-

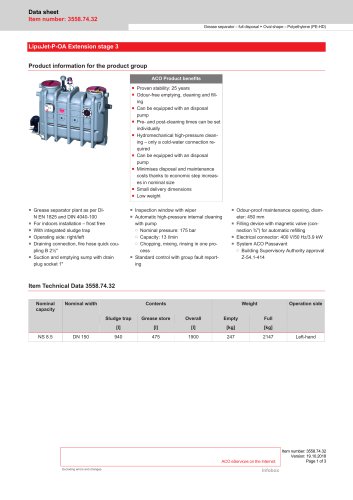

LipuJet-P-OAP 3558.84.32

3 Pages

-

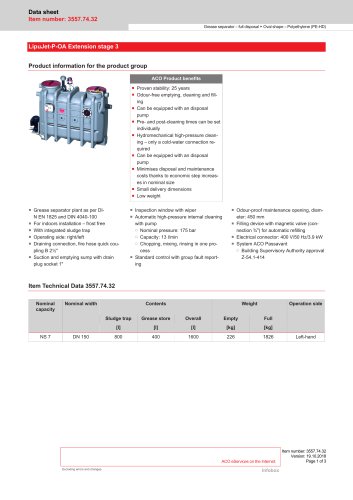

LipuJet-P-OAP 3557.84.32

3 Pages

-

LipuJet-P-OAP 3555.84.32

3 Pages

-

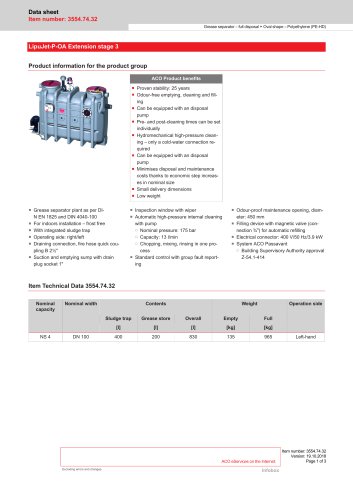

LipuJet-P-OAP 3554.84.32

3 Pages

-

LipuJet-P-OAP 3553.84.32

3 Pages

-

LipuJet-P-OAP 3552.84.32

3 Pages

-

LipuJet-P-OAP 3551.84.32

3 Pages

-

LipuJet-P-OA 3560.74.32

3 Pages

-

LipuJet-P-OA 3558.74.32

3 Pages

-

LipuJet-P-OA 3557.74.32

3 Pages

-

LipuJet-P-OA 3554.74.32

3 Pages

-

LipuJet-P-OA 3553.74.32

3 Pages

-

LipuJet-P-OA 3552.74.32

3 Pages

-

LipuJet-P-OA 3551.74.32

3 Pages

-

LipuJet-P-OB 3560.34.00

3 Pages

-

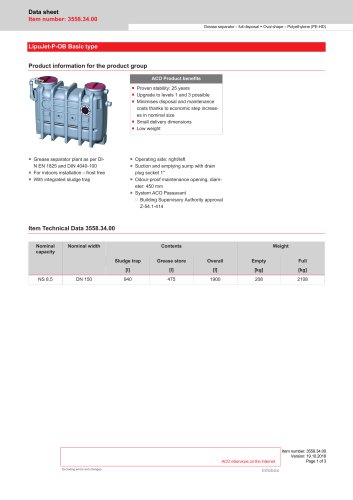

LipuJet-P-OB 3558.34.00

3 Pages

-

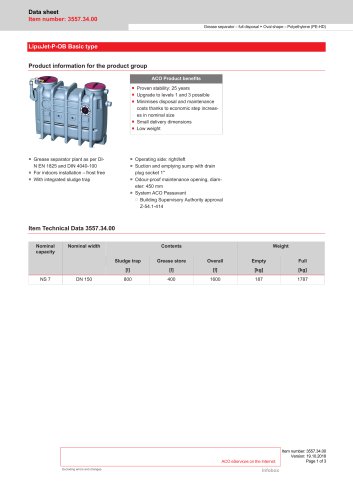

LipuJet-P-OB 3557.34.00

3 Pages

-

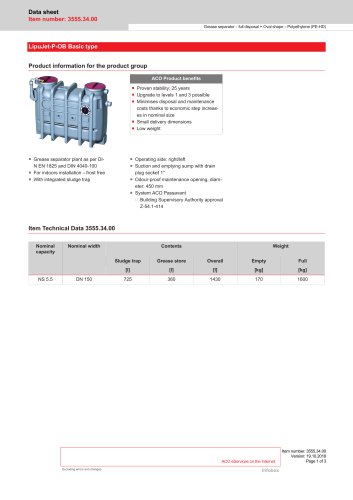

LipuJet-P-OB 3555.34.00

3 Pages

-

LipuJet-P-OB 3554.34.00

3 Pages

-

LipuJet-P-OB 3553.34.00

3 Pages

-

LipuJet-P-OB 3552.34.00

3 Pages

-

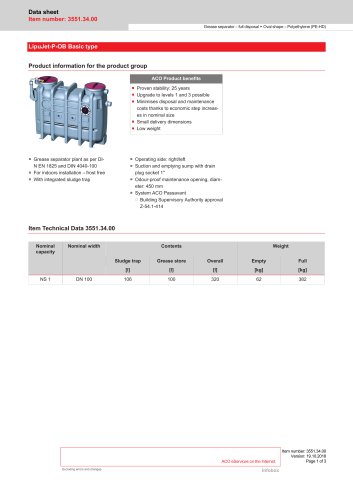

LipuJet-P-OB 3551.34.00

3 Pages

-

Lipumax P-D Intermedi

52 Pages

-

Lipumax P-DM High Manual Co

52 Pages

-

Lipumax P-B Basic

52 Pages

-

Pipe®

36 Pages

-

AS2001 Tray Channel

20 Pages

-

Rainwater Outlets

32 Pages

-

Mobile separators

4 Pages

-

Junior® Backflow

2 Pages

-

Quatrix® without Chamber

2 Pages

-

uatrix® with Chamber

2 Pages

-

riplex® with Chamber

2 Pages

-

AS701 Upstand

2 Pages

-

AS801 Micro Channel

2 Pages

-

AS901 Hi Load

2 Pages

-

Shower Gratings

2 Pages

-

BD June Event Summary Binder

185 Pages

-

Railway Brochure

20 Pages

-

Biological Grease Traps

28 Pages

-

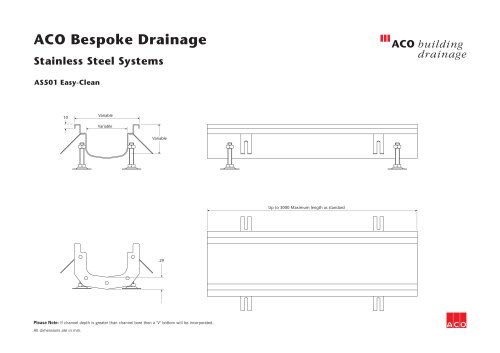

AS501

2 Pages

-

AS401

2 Pages

-

AS301

2 Pages

-

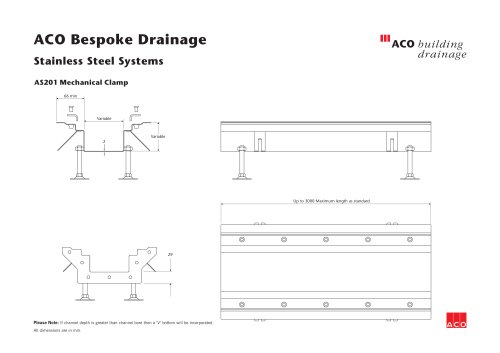

AS201

2 Pages

-

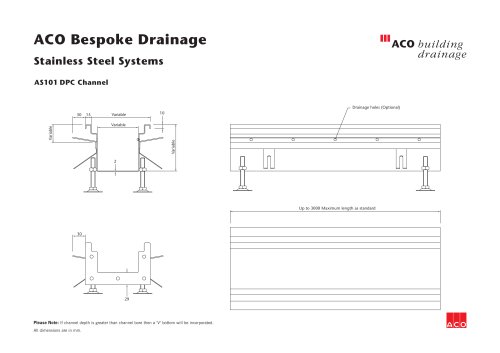

AS101

2 Pages

-

Radius Channel

2 Pages

-

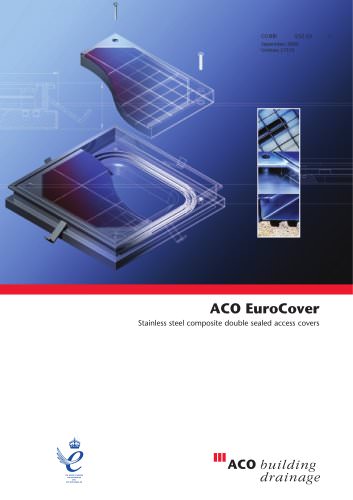

Eurocover Access Cover

8 Pages

-

Alucover Access Cover

2 Pages

-

FreeDeck

20 Pages

-

Pipe®

60 Pages

-

Stainless Steel Gully Systems

56 Pages

-

Bath-to-Wetroom Adaptor

2 Pages

-

Walk-in Solution

18 Pages

-

Easyflow

16 Pages

-

Shower Gullies

35 Pages

-

Shower Channels

48 Pages

-

Wetroom Former

2 Pages