Catalog excerpts

Drainage management for the Food Processing Industry

Open the catalog to page 1

ACO. The future of drainage. The ACO Group offers sustainable, integrated drainage systems designed to protect your business and the environment. Our aim is to constantly improve every aspect of safety, hygiene and functional performance. We believe our systems and services are truly unique, delivering unparalleled benefits to everyone involved in project delivery or subsequent operation. ACO worldwide With over 60 years experience in the design and manufacture of drainage components ACO have developed a unique global competence that has resulted in development of innovative and award...

Open the catalog to page 2

ACO in the Food processing industry Food touches every single individual on the planet in various aspects: health, pleasure, socialisation. More broadly food safety and access to food are fundamental prerequisites for public health, social stability but are also paramount for business sustainability and profitability. Drainage is a critical component affecting the hygienic performance of food production facilities. Effective drainage helps mitigate hazards from the external environment and is central to the safe and hygienic operation internally. Within the food production facility, surface...

Open the catalog to page 3

Open product area low risk — high care — high risk The British Retail Consortium (BRC Version 6, http://www.brcglobalstandards.com) identifies four different risk zones (low risk, high risk, high care, enclosed product area) within the processing and storage facilities, with corresponding levels of hygiene requirements and segregation to reduce the potential for product contamination. Drainage, as other aspects of factory hygiene, should reflect the potential risk of hazards to food. ACO recognizes the different risks in all four food production and in non-production zones and has...

Open the catalog to page 4

ACO hygienic design features ACO gully takes hygienic performance one step further. We apply standards reserved for food contact surfaces EN 1672 and EN ISO 14159 to the gully design. All our building drainage products are of course tested according to the relevant European standards. All radiuses larger than 3mm which greatly increases cleaning effectiveness Edge in-fill ensures stable and durable transmission between the gully and surrounding floor and helps to minimize risk of floor cracks which could harbour microorganism Deep-drawn body ensures smooth contours eliminating crevices that...

Open the catalog to page 5

ACO gully With 3 body sizes, this range caters for various flow rates and construction requirements including shallow construction depths and applications where preventative fire measures are required. Hygienically, the new gully range excels: it incorporates many hygienic features required of food processing equipment – surpassing any requirement for a drainage product. Certified to EN 1253. ACO tray channels High capacity channels that offer exceptional control for large volumes of fluid. This range is ideal for applications where considerable volumes may be discharged quickly. All tray...

Open the catalog to page 6

packaging materials storage raw finish product storage dispatch area transfer pipework enclosed equipment fully aseptic filling equipment filling ACO drainage designed to primarily intercept and convey large volume of waste water, emphasis on safety, hygiene, and clean-ability. ACO gullies ACO tray channels ACO box channels ACO slot channels Non - food production area is internally separated by walls from departments in which food manufacturing activities take place. Separation have to be sufficient to prevent contamination of food production areas by pest, particulates gases and fumes....

Open the catalog to page 7

Factory site Modern food production facilities are designed to protect foods from the risk of environmental hazards. Particularly where sites produce ready-to-eat products, the design of the drainage systems must protect high risk and high care areas by the installation of equipment fitted to prevent back up of waste water. Serious problems are related to potential ingress of surface water into the production facility and / or back up in the sewerage system. In more modern schemes, site connection will be to surface water sewer only and in many cases, no sewer at all. In such situations the...

Open the catalog to page 8

Product portfolio ACO StormBrixx is a unique and patented plastic geocellular storm water management system. Designed for surface water infiltration and storage, its versatility allows it to be used in applications across all construction environments as a standalone solution or as part of an integrated sustainable drainage (SUDS) scheme. ACO Qmax has been developed to satisfy the demand for a versatile, high capacity slot drainage system for a wide range of applications involving small to large catchment areas to any load class. The system is specifically designed to form an integral part...

Open the catalog to page 9All ACO Building Drainage catalogs and technical brochures

-

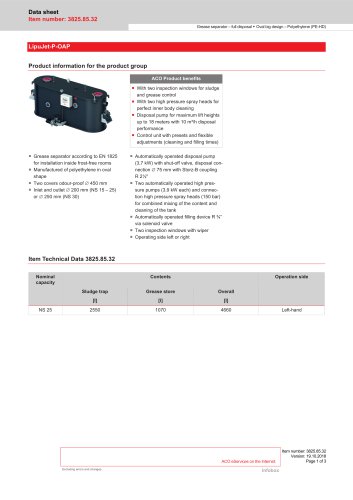

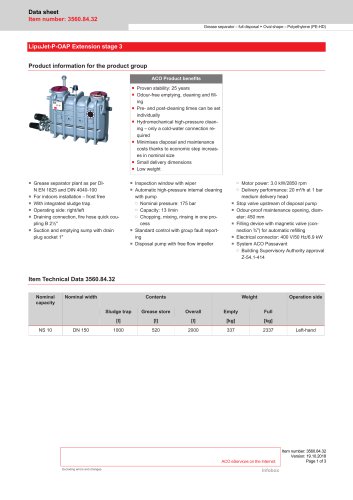

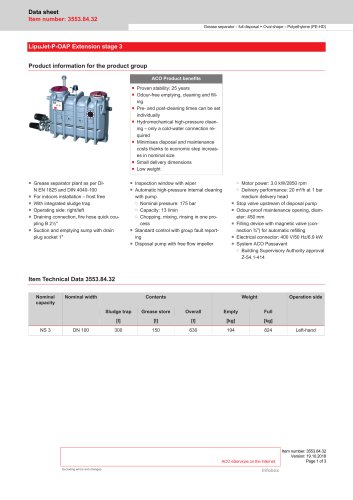

LipuJet-P-OAP 3830.85.32

3 Pages

-

LipuJet-P-OAP 3825.85.32

3 Pages

-

LipuJet-P-OAP

3 Pages

-

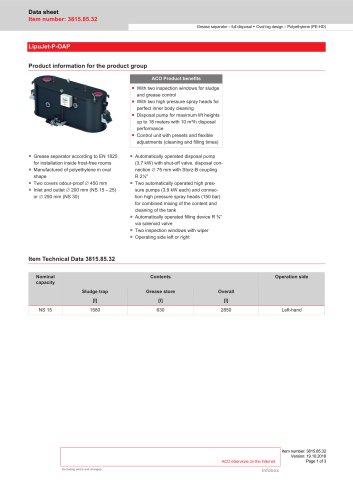

LipuJet-P-OAP 3815.85.32

3 Pages

-

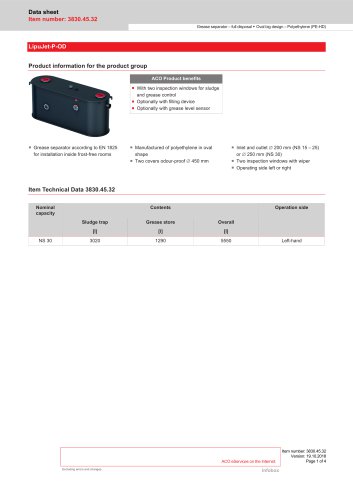

LipuJet-P-OD 3830.45.32

4 Pages

-

LipuJet-P-OD 3825.45.32

4 Pages

-

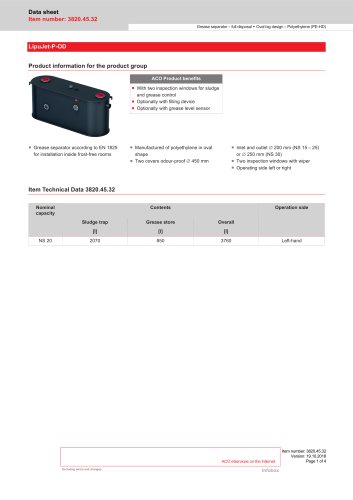

LipuJet-P-OD 3820.45.32

4 Pages

-

LipuJet-P-OD 3815.45.32

4 Pages

-

LipuJet-P-OB 3830.35.42

4 Pages

-

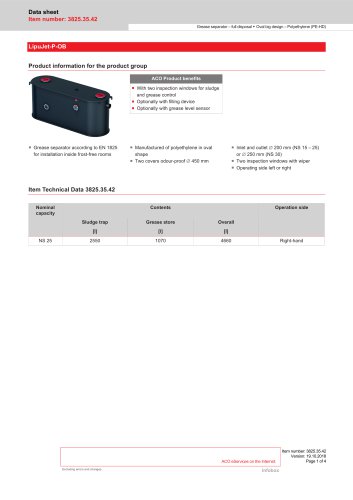

LipuJet-P-OB 3825.35.42

4 Pages

-

LipuJet-P-OB 3820.35.42

4 Pages

-

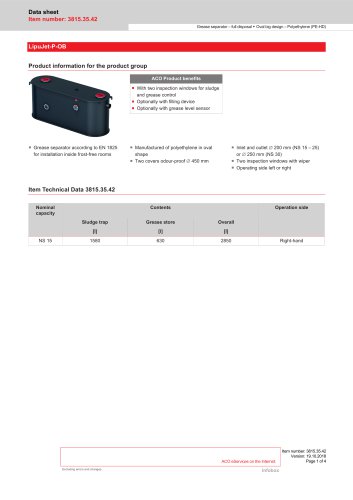

LipuJet-P-OB 3815.35.42

4 Pages

-

LipuJet-P-OAP 3560.84.32

3 Pages

-

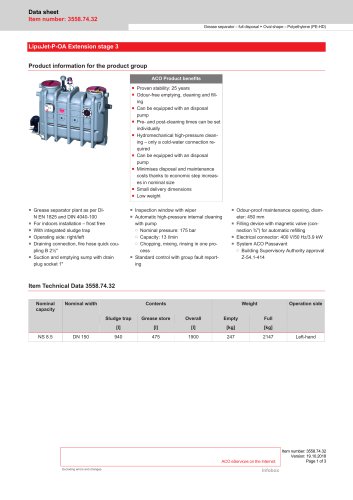

LipuJet-P-OAP 3558.84.32

3 Pages

-

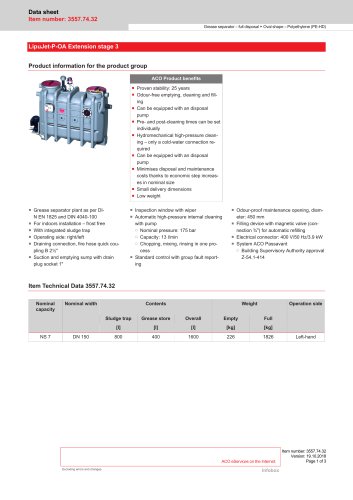

LipuJet-P-OAP 3557.84.32

3 Pages

-

LipuJet-P-OAP 3555.84.32

3 Pages

-

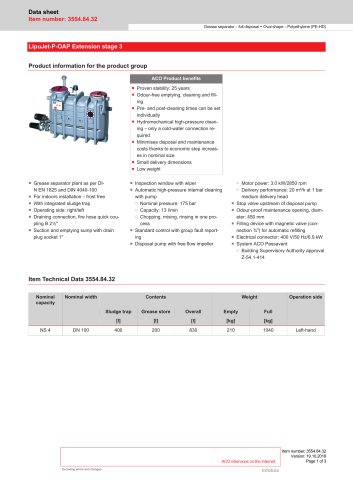

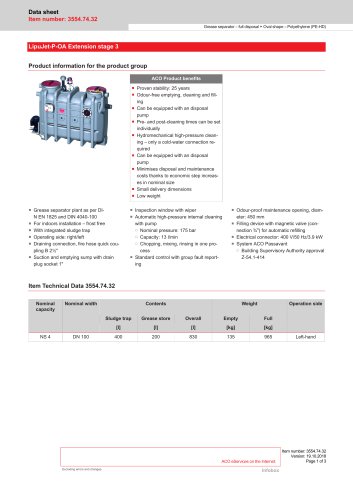

LipuJet-P-OAP 3554.84.32

3 Pages

-

LipuJet-P-OAP 3553.84.32

3 Pages

-

LipuJet-P-OAP 3552.84.32

3 Pages

-

LipuJet-P-OAP 3551.84.32

3 Pages

-

LipuJet-P-OA 3560.74.32

3 Pages

-

LipuJet-P-OA 3558.74.32

3 Pages

-

LipuJet-P-OA 3557.74.32

3 Pages

-

LipuJet-P-OA 3554.74.32

3 Pages

-

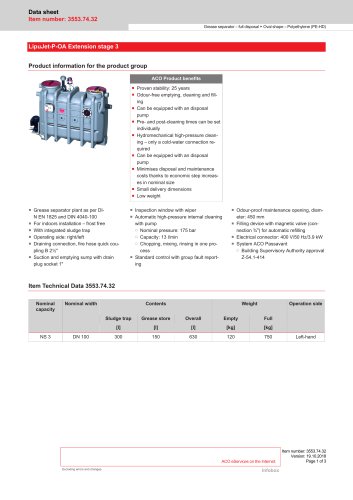

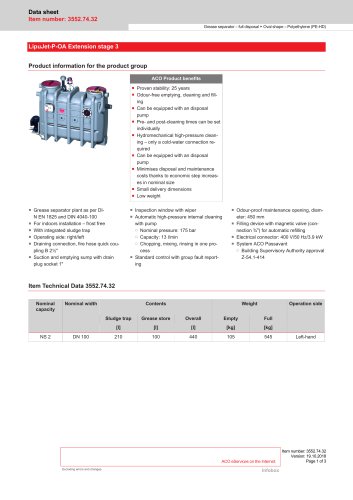

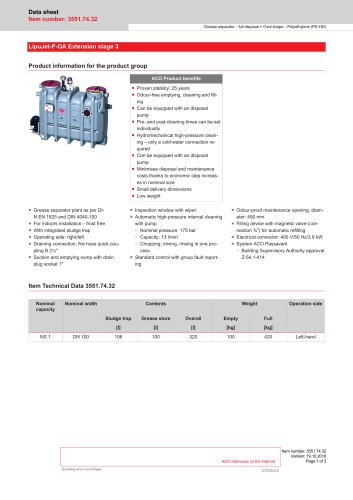

LipuJet-P-OA 3553.74.32

3 Pages

-

LipuJet-P-OA 3552.74.32

3 Pages

-

LipuJet-P-OA 3551.74.32

3 Pages

-

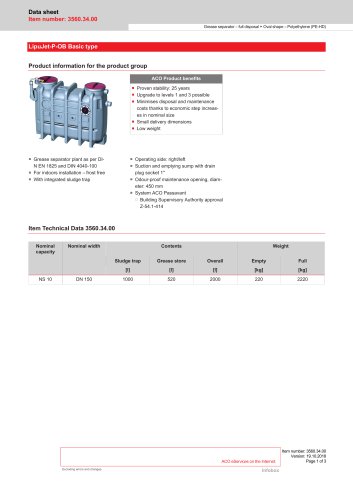

LipuJet-P-OB 3560.34.00

3 Pages

-

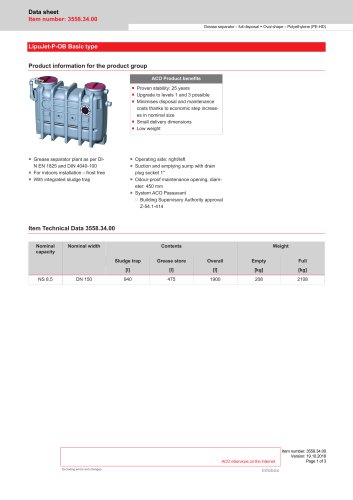

LipuJet-P-OB 3558.34.00

3 Pages

-

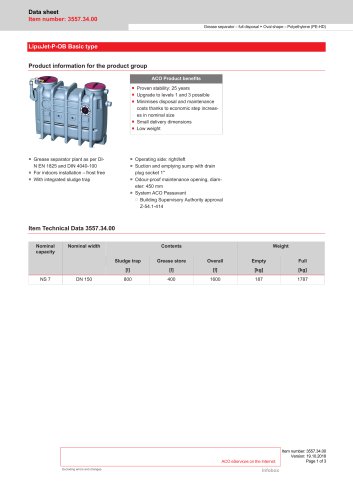

LipuJet-P-OB 3557.34.00

3 Pages

-

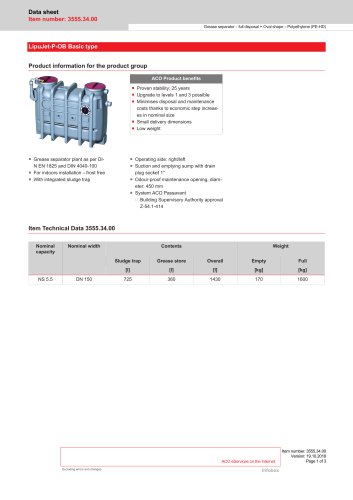

LipuJet-P-OB 3555.34.00

3 Pages

-

LipuJet-P-OB 3554.34.00

3 Pages

-

LipuJet-P-OB 3553.34.00

3 Pages

-

LipuJet-P-OB 3552.34.00

3 Pages

-

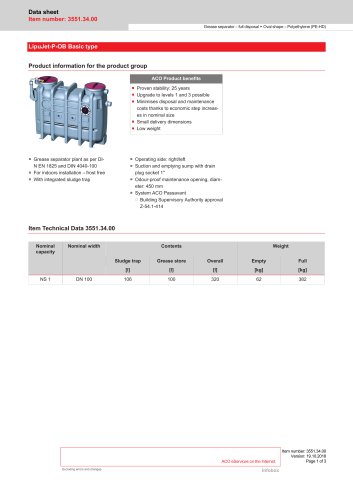

LipuJet-P-OB 3551.34.00

3 Pages

-

Lipumax P-D Intermedi

52 Pages

-

Lipumax P-DM High Manual Co

52 Pages

-

Lipumax P-B Basic

52 Pages

-

Pipe®

36 Pages

-

AS2001 Tray Channel

20 Pages

-

Rainwater Outlets

32 Pages

-

Mobile separators

4 Pages

-

Junior® Backflow

2 Pages

-

Quatrix® without Chamber

2 Pages

-

uatrix® with Chamber

2 Pages

-

riplex® with Chamber

2 Pages

-

AS701 Upstand

2 Pages

-

AS801 Micro Channel

2 Pages

-

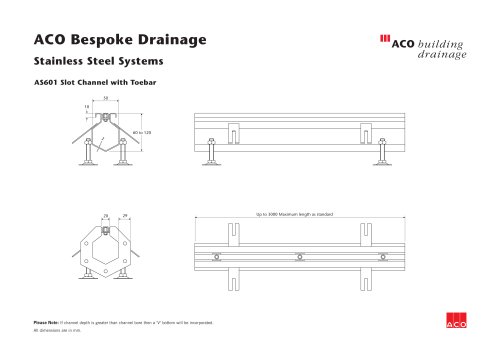

AS901 Hi Load

2 Pages

-

Shower Gratings

2 Pages

-

BD June Event Summary Binder

185 Pages

-

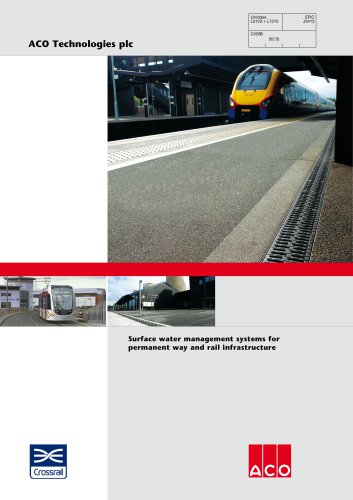

Railway Brochure

20 Pages

-

Biological Grease Traps

28 Pages

-

Grease Separators

52 Pages

-

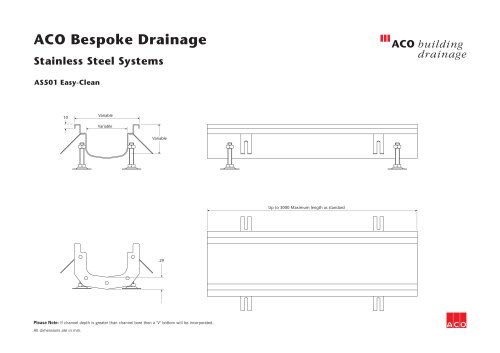

AS501

2 Pages

-

AS401

2 Pages

-

AS301

2 Pages

-

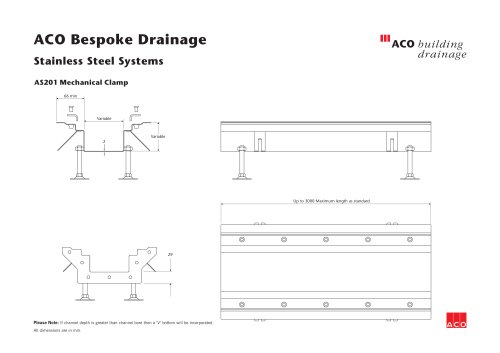

AS201

2 Pages

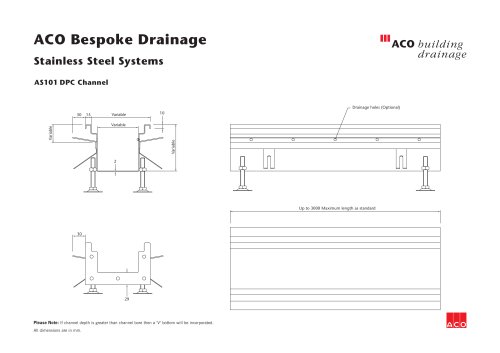

-

AS101

2 Pages

-

Radius Channel

2 Pages

-

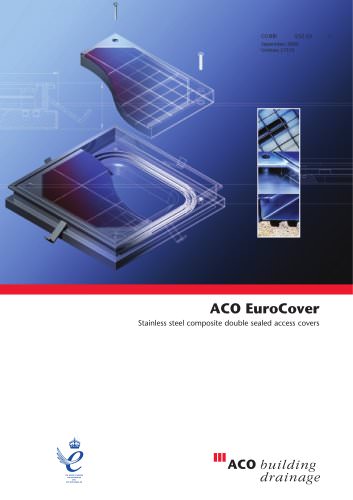

Eurocover Access Cover

8 Pages

-

Alucover Access Cover

2 Pages

-

FreeDeck

20 Pages

-

Pipe®

60 Pages

-

Stainless Steel Gully Systems

56 Pages

-

Bath-to-Wetroom Adaptor

2 Pages

-

Walk-in Solution

18 Pages

-

Easyflow

16 Pages

-

Shower Gullies

35 Pages

-

Shower Channels

48 Pages

-

Wetroom Former

2 Pages