Catalog excerpts

Drainage management in the Commercial kitchen

Open the catalog to page 1

The ACO group in commercial kitchens All commercial kitchens can be characterised as a hazardous working environment – they are extremely busy with the potential for wet and greasy floors due to the abundance of fluids in both cooking and cleaning and they are hot! In combination these factors may affect both food hygiene and health & safety aspects of the kitchen. Efficient drainage is one of the fundamental requirements; operationally it helps prevent accidents; hygienically, it is embodied in European Law-EC 852 – the hygiene of foodstuffs. ACO is a global producer and supplier of...

Open the catalog to page 2

Storage and preparation Storage area Food storage areas will require occasional clean down as part of either a planned programme or in case of spillage. In many cases capacity of the floor drain need only accommodate low flows. The choice between channel and gully is dependent on the nature of the operation, gullies may be preferred but where box channels are used, a narrow, shallow system with a build in gradient is advantageous. Ideally the drainage unit will be accessible allowing water to be directed to it, and enabling easy cleaning and maintenance of the drain itself. Gratings should...

Open the catalog to page 4

Production area Kitchen The busy heart of the kitchen, where potentially most slips & falls can occur, requires the strategic positioning of floor drainage to aid in the removal of water that is being used in, or discharged from specialist cooking equipment such as Bratt Pans, Boiling Pans and Combination Ovens. The sizing and positioning of box and tray channels, tundishes or gullies for these appliances should be coordinated with the specialist designers or equipment manufacturers in order to prevent splashing of water, oil and food debris on to the surrounding surfaces. The perimeter of...

Open the catalog to page 5

Washing and disposal area Ware washing operations involve the removal of residual food, racking, pre-soaking, rinsing and washing stages. Care must be taken to reduce the build up of fats oils and grease in drainage plumbing and simply wiping off food residues can have a dramatic impact on the overall system. Floor drainage also features predominantly in these areas, specifically in front of larger conveyor or “flight” type washers, but equally centrally to any dishwash or potwash area, as these rooms are traditionally the wettest in the kitchen operation. Box channel runs are useful in...

Open the catalog to page 6

ACO focus on three principle attributes in product conception and design ACO gullies With 3 body sizes, this range caters for various flow rates and construction requirements including shallow construction depths and applications where preventative fire measures are required. Hygienically, the new gully range excels: it incorporates many hygienic features required of food processing equipment – surpassing any requirement for a drainage product. Certified to EN 1124, Ct Mark. ACO tray channels High capacity channels that offer exceptional control for large volumes of fluid. This range is...

Open the catalog to page 7

Andreas Müller Executive Chef of “Alte Meierei” Rendsburg, Germany Colin Waterton, General Manager of the operation, ASL Nigeria The ACO Food Waste Disposal System “Waste Jet” provides additional hygienic value for our daily kitchen operation. Due to the short removal methods through the food waste disposal unit, there are no problems with lost food scraps on the floor any longer. ACO drainage was originally specified by the design consultant on our project for standard gullies, however drainage channels, and a large washdown grating were then specifically designed and flown in for our...

Open the catalog to page 8All ACO Building Drainage catalogs and technical brochures

-

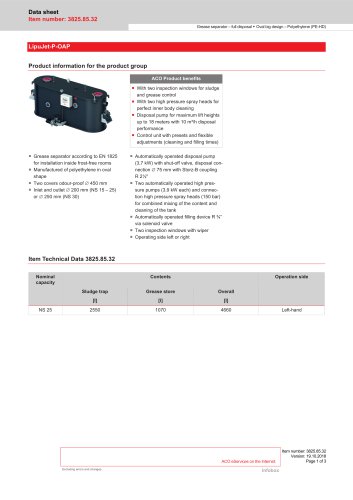

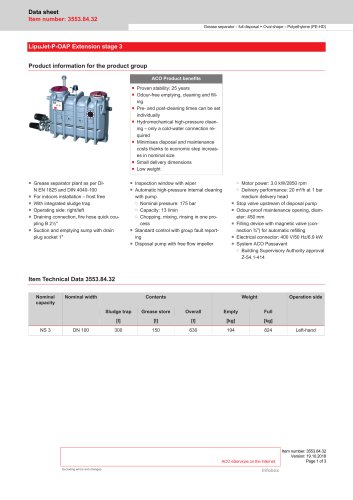

LipuJet-P-OAP 3830.85.32

3 Pages

-

LipuJet-P-OAP 3825.85.32

3 Pages

-

LipuJet-P-OAP

3 Pages

-

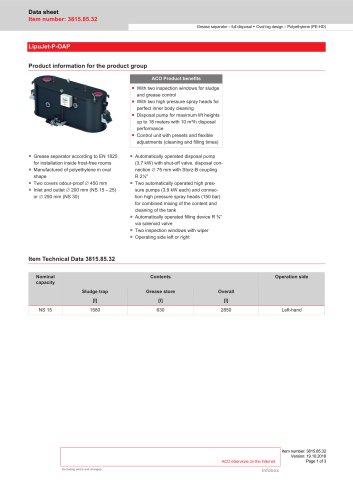

LipuJet-P-OAP 3815.85.32

3 Pages

-

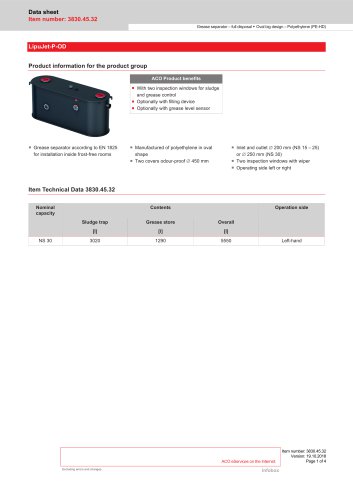

LipuJet-P-OD 3830.45.32

4 Pages

-

LipuJet-P-OD 3825.45.32

4 Pages

-

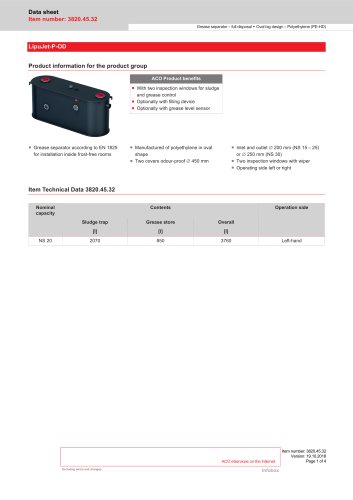

LipuJet-P-OD 3820.45.32

4 Pages

-

LipuJet-P-OD 3815.45.32

4 Pages

-

LipuJet-P-OB 3830.35.42

4 Pages

-

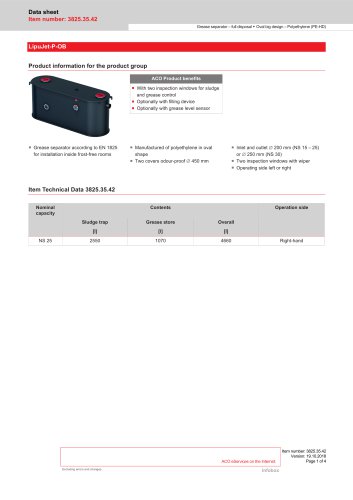

LipuJet-P-OB 3825.35.42

4 Pages

-

LipuJet-P-OB 3820.35.42

4 Pages

-

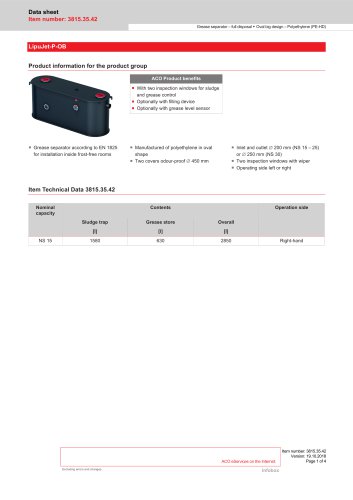

LipuJet-P-OB 3815.35.42

4 Pages

-

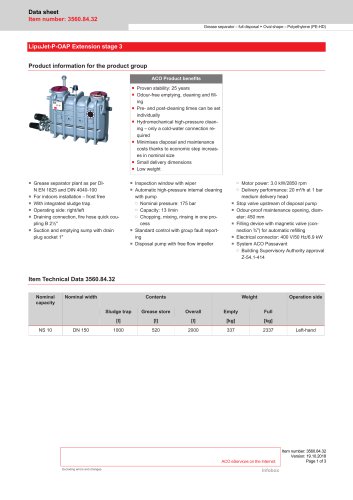

LipuJet-P-OAP 3560.84.32

3 Pages

-

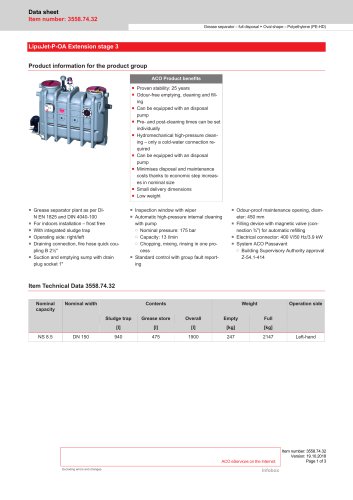

LipuJet-P-OAP 3558.84.32

3 Pages

-

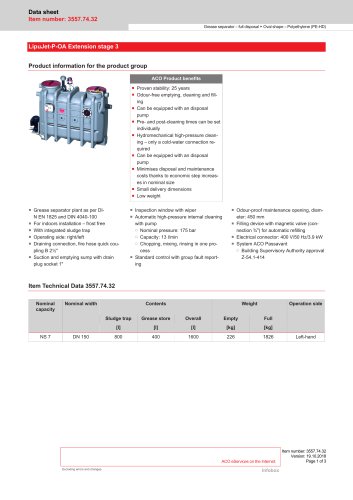

LipuJet-P-OAP 3557.84.32

3 Pages

-

LipuJet-P-OAP 3555.84.32

3 Pages

-

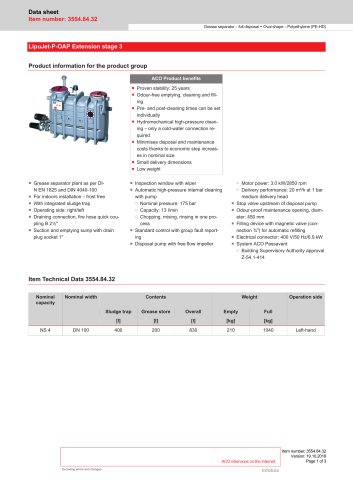

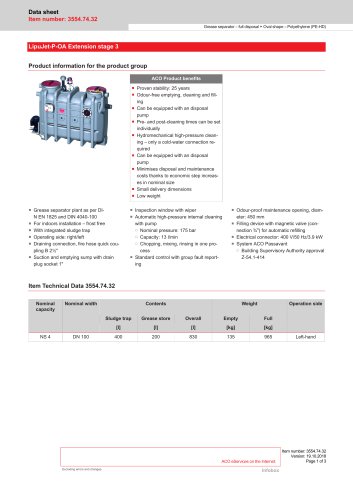

LipuJet-P-OAP 3554.84.32

3 Pages

-

LipuJet-P-OAP 3553.84.32

3 Pages

-

LipuJet-P-OAP 3552.84.32

3 Pages

-

LipuJet-P-OAP 3551.84.32

3 Pages

-

LipuJet-P-OA 3560.74.32

3 Pages

-

LipuJet-P-OA 3558.74.32

3 Pages

-

LipuJet-P-OA 3557.74.32

3 Pages

-

LipuJet-P-OA 3554.74.32

3 Pages

-

LipuJet-P-OA 3553.74.32

3 Pages

-

LipuJet-P-OA 3552.74.32

3 Pages

-

LipuJet-P-OA 3551.74.32

3 Pages

-

LipuJet-P-OB 3560.34.00

3 Pages

-

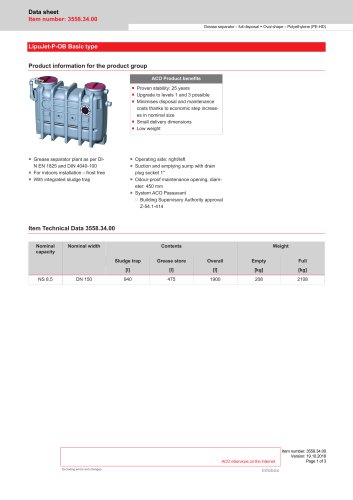

LipuJet-P-OB 3558.34.00

3 Pages

-

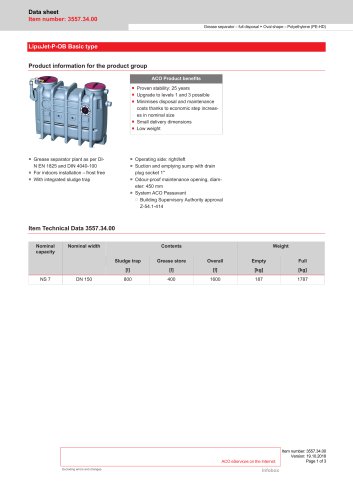

LipuJet-P-OB 3557.34.00

3 Pages

-

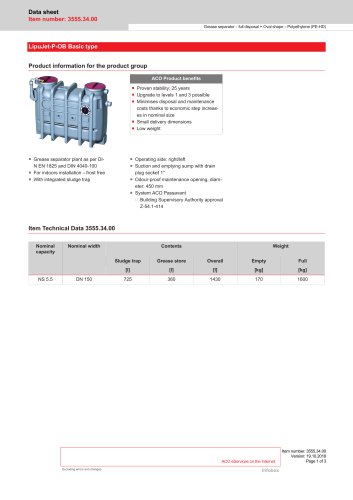

LipuJet-P-OB 3555.34.00

3 Pages

-

LipuJet-P-OB 3554.34.00

3 Pages

-

LipuJet-P-OB 3553.34.00

3 Pages

-

LipuJet-P-OB 3552.34.00

3 Pages

-

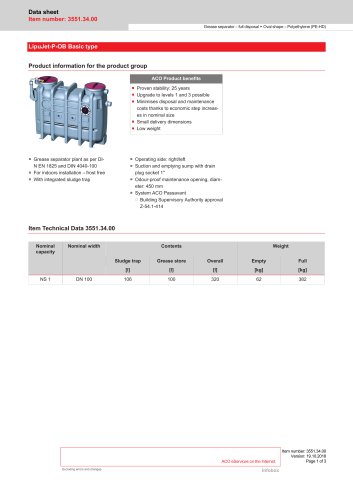

LipuJet-P-OB 3551.34.00

3 Pages

-

Lipumax P-D Intermedi

52 Pages

-

Lipumax P-DM High Manual Co

52 Pages

-

Lipumax P-B Basic

52 Pages

-

Pipe®

36 Pages

-

AS2001 Tray Channel

20 Pages

-

Rainwater Outlets

32 Pages

-

Mobile separators

4 Pages

-

Junior® Backflow

2 Pages

-

Quatrix® without Chamber

2 Pages

-

uatrix® with Chamber

2 Pages

-

riplex® with Chamber

2 Pages

-

AS701 Upstand

2 Pages

-

AS801 Micro Channel

2 Pages

-

AS901 Hi Load

2 Pages

-

Shower Gratings

2 Pages

-

BD June Event Summary Binder

185 Pages

-

Railway Brochure

20 Pages

-

Biological Grease Traps

28 Pages

-

Grease Separators

52 Pages

-

AS501

2 Pages

-

AS401

2 Pages

-

AS301

2 Pages

-

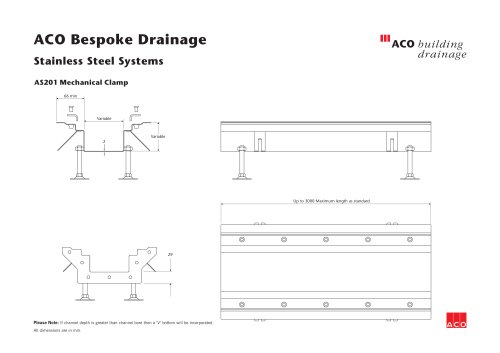

AS201

2 Pages

-

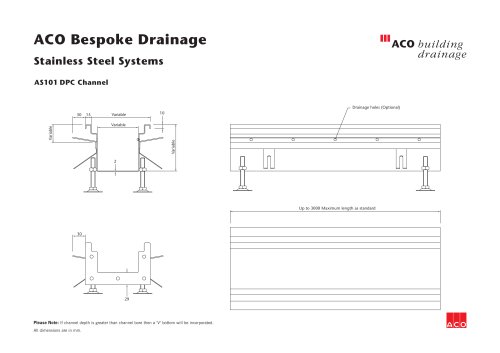

AS101

2 Pages

-

Radius Channel

2 Pages

-

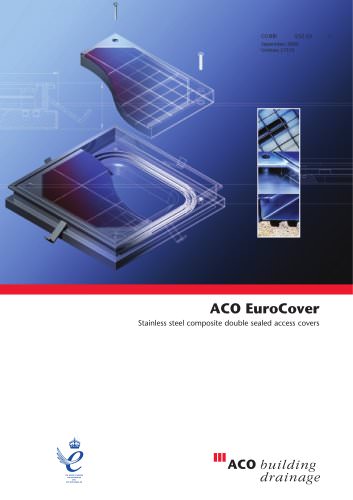

Eurocover Access Cover

8 Pages

-

Alucover Access Cover

2 Pages

-

FreeDeck

20 Pages

-

Pipe®

60 Pages

-

Stainless Steel Gully Systems

56 Pages

-

Bath-to-Wetroom Adaptor

2 Pages

-

Walk-in Solution

18 Pages

-

Easyflow

16 Pages

-

Shower Gullies

35 Pages

-

Shower Channels

48 Pages

-

Wetroom Former

2 Pages