Catalog excerpts

Grease Management Product catalogue ACO Biological Grease Traps - Grease management handbook

Open the catalog to page 1

ACO Building Drainage Our built environment is becoming ever more Our global resources and fabrication capacity ACO Building Drainage is a division of ACO complex. Applications are becoming more make it possible for us to deliver best value, Technologies plc and part of the worldwide sophisticated and the increasing pressure of both with our standard products and with our ACO Group. The Group has sales in excess of regulations and standards make achieving bespoke designs. Confidence is further £500 million worldwide with production design, performance and financial goals ever assured with...

Open the catalog to page 2

ACO Biological Grease Traps The need for fat, oil and grease management Local effects of fats, oils and grease (FOG’s) Regional effects System and process Overview System components and FOG management variables Biological activators Selecting a grease traps Factors to consider Grease trap sizing Load Class Below ground polypropylene grease traps Features and benefits Technical data Free standing polypropylene grease traps Features and benefits Technical data Free standing stainless steel grease traps Features and benefits Technical data Free standing stainless steel grease trap – compact...

Open the catalog to page 3

ACO Biological Grease Traps The need for fat, oil and grease management Local effects of fats, oils and grease (FOG’s) One of the greatest drainage problems faced in kitchens and food processing areas is the accumulation of fats, oils and greases within the drainage system. Reduced efficiency Cooking plant Potential flooding Process plant Note: As FOG’s cool in the drainage system they can solidify. If untreated, accumulation eventually leads to drainage system failure leading to health hazards within the food preparation area. Combined output Regional effects Drainage infrastructure...

Open the catalog to page 4

ACO Biological Grease Traps System and process Overview All ACO Building Drainage biological present in the drain waste. It is important to grease traps work on the same principles: note that the sediment basket volume is a biological activator is periodically injected limited, therefore any significant amounts of Separation occurs relatively quickly, thereby into the connecting drainage pipe upstream debris should be removed before entering the allowing less contaminated water to flow to grease trap. the outlet drain during periods of intense use. The mixture of contaminated water and The...

Open the catalog to page 5

ACO Biological Grease Traps System and process Biological activators Unlike strong acid or caustic drain cleaners, i) The activator introduces an enzyme that Biological activators will not digest solid ACO biological activator works safely, but assists the natural biological process of residues from the food preparation process more slowly. It can be used to unblock drains breaking down long molecular chain FOG’s quickly, so the sediment bucket requires and to replace aggressive caustic and acid into a manageable solution to then be periodic removal for cleaning to ensure discharged safely...

Open the catalog to page 6

ACO Biological Grease Traps Selecting a grease trap Factors to consider Grease trap size Other points Biological traps are selected on “meals BS EN 1825 conforming gravity separators available to special order. Free standing traps available for 50, Traps can be installed in parallel to meet greater capacity requirements. Below ground traps available for up to 1000 meals per day. Location - Below Ground Polypropylene grease traps (BGP) range Page 10-12 Suitable for internal or external use. Recessed cover to FACTA Load Class A. Appropriate where drainage inlet invert Recessed or solid cover...

Open the catalog to page 7

ACO Biological Grease Traps Selecting a grease trap Grease trap sizing Selecting the correct size of grease trap for a The amount of fats, oils and greases (FOG’s) Further information may be at hand relating to particular application is probably the most generated in the food processing area is the number of covers expected at a particular difficult task facing the specifier as each generally proportional to the food volume sitting. In this case the simple table below installation tends to be unique in the produced. Therefore the most reliable and can be used to calculate meals per day....

Open the catalog to page 8

ACO Biological Grease Traps Selecting a grease trap Load Class All ACO Building Drainage products have load classification in accordance with the FACTA (Fabricated Access Covers Trade Association) Load Class criteria. The Load Class table below is provided as a guide only in the selection of fabricated metal gratings and covers for the applications indicated and has been designed specifically to cater for the performance of these products in service. With respect to EN load test standards, the characteristics of stainless steel and mild steel materials are not addressed within their load...

Open the catalog to page 9

ACO Biological Grease Traps Below ground polypropylene grease traps Features and benefits Recessed cover FACTA Load Class B. Solid chequer plate cover FACTA Load Class B. Recessed cover FACTA Load Class D. Solid chequer plate cover FACTA Load Class A. Slotted screw four point locking cover for convenient removal. Sealed system on all covers. Four point lifting key. Robust, fully welded hot dip galvanised finish. 300mm raising piece option easily cut on-site to length. 10 Six sizes up to 15 l/s or 1000 meals per day capacity. 11 Robust, fully welded lightweight and corrosion resistant 11...

Open the catalog to page 10

ACO Biological Grease Traps Below ground polypropylene grease traps Technical data Product Dimensions - BGP Range Base to Inlet Invert B mm Solid access cover - FACTA Load Class A Description BGPSA Cover and frame weight combined Solid cover weight Filled recessed cover weight Solid access cover - FACTA Load Class B Description BGPSB Cover and frame weight combined Solid cover weight Filled recessed cover weight

Open the catalog to page 11

ACO Biological Grease Traps Below ground polypropylene grease traps Technical data Recessed access cover - FACTA Load Class B Cover and frame weight combined Solid cover weight Filled recessed cover weight Recessed access cover - FACTA Load Class D Cover and frame weight combined Solid cover weight Filled recessed cover weight Description BGPRP NBS specification clause reference For relevant NBS specification, refer to NBS Section R12 Below Ground Drainage, Clause 630 Grease Traps/convertors. Access cover raising piece

Open the catalog to page 12All ACO Building Drainage catalogs and technical brochures

-

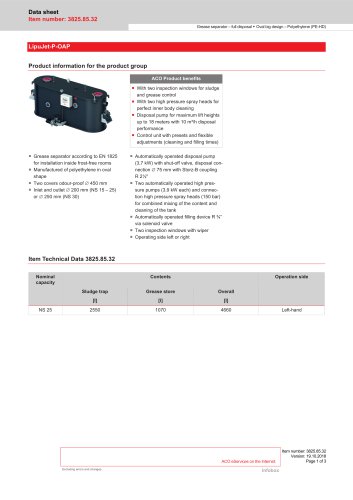

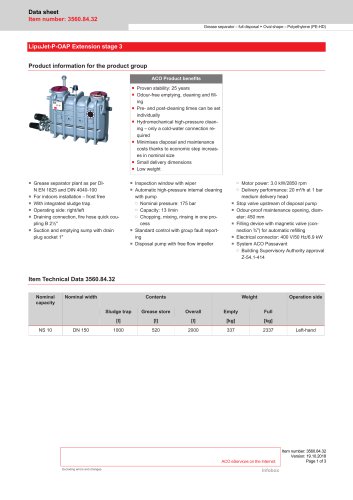

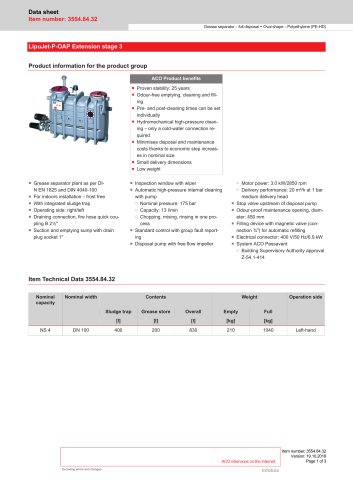

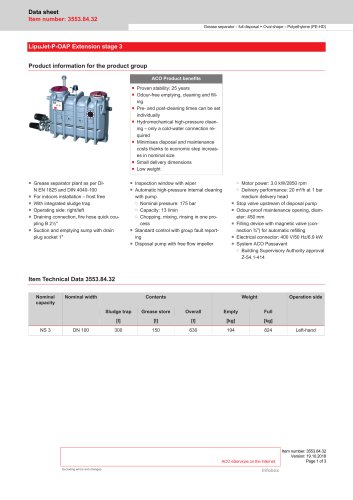

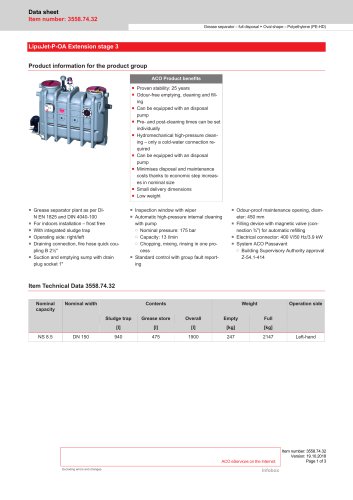

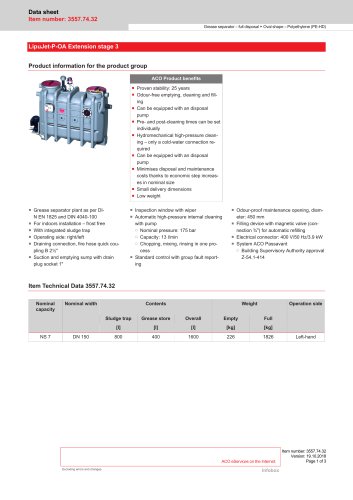

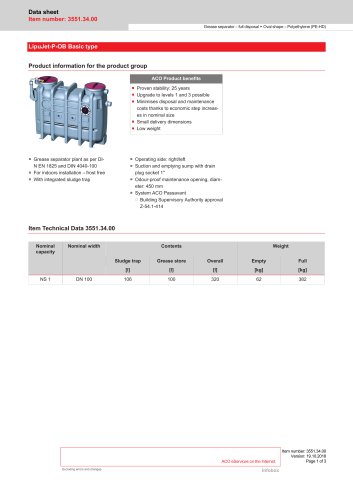

LipuJet-P-OAP 3830.85.32

3 Pages

-

LipuJet-P-OAP 3825.85.32

3 Pages

-

LipuJet-P-OAP

3 Pages

-

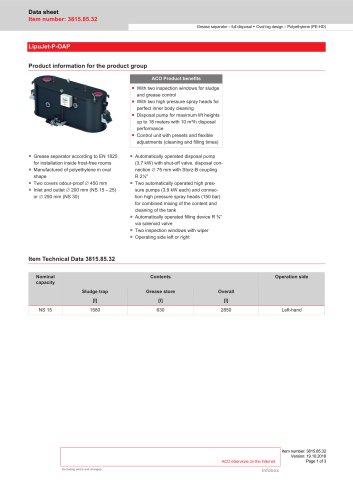

LipuJet-P-OAP 3815.85.32

3 Pages

-

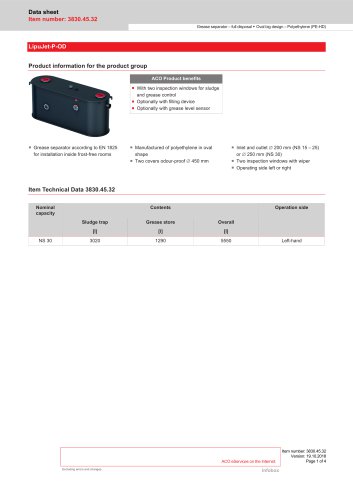

LipuJet-P-OD 3830.45.32

4 Pages

-

LipuJet-P-OD 3825.45.32

4 Pages

-

LipuJet-P-OD 3820.45.32

4 Pages

-

LipuJet-P-OD 3815.45.32

4 Pages

-

LipuJet-P-OB 3830.35.42

4 Pages

-

LipuJet-P-OB 3825.35.42

4 Pages

-

LipuJet-P-OB 3820.35.42

4 Pages

-

LipuJet-P-OB 3815.35.42

4 Pages

-

LipuJet-P-OAP 3560.84.32

3 Pages

-

LipuJet-P-OAP 3558.84.32

3 Pages

-

LipuJet-P-OAP 3557.84.32

3 Pages

-

LipuJet-P-OAP 3555.84.32

3 Pages

-

LipuJet-P-OAP 3554.84.32

3 Pages

-

LipuJet-P-OAP 3553.84.32

3 Pages

-

LipuJet-P-OAP 3552.84.32

3 Pages

-

LipuJet-P-OAP 3551.84.32

3 Pages

-

LipuJet-P-OA 3560.74.32

3 Pages

-

LipuJet-P-OA 3558.74.32

3 Pages

-

LipuJet-P-OA 3557.74.32

3 Pages

-

LipuJet-P-OA 3554.74.32

3 Pages

-

LipuJet-P-OA 3553.74.32

3 Pages

-

LipuJet-P-OA 3552.74.32

3 Pages

-

LipuJet-P-OA 3551.74.32

3 Pages

-

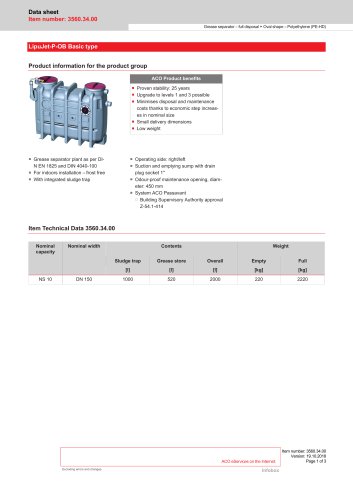

LipuJet-P-OB 3560.34.00

3 Pages

-

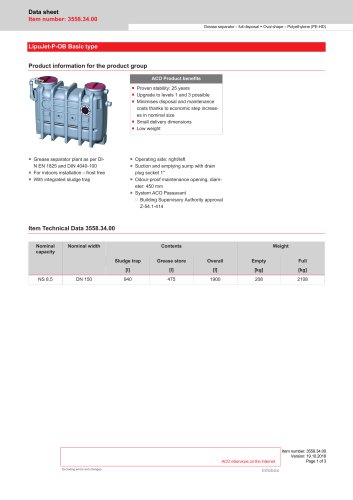

LipuJet-P-OB 3558.34.00

3 Pages

-

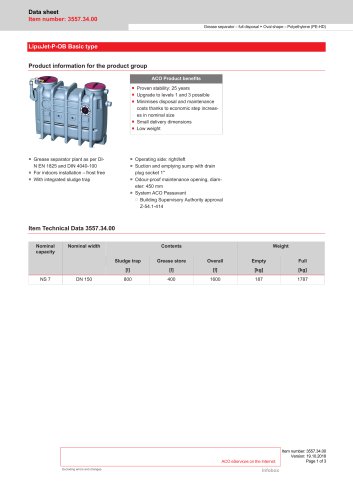

LipuJet-P-OB 3557.34.00

3 Pages

-

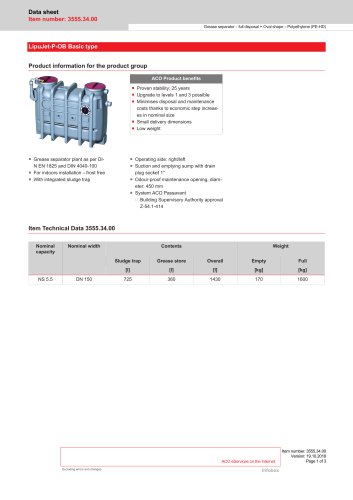

LipuJet-P-OB 3555.34.00

3 Pages

-

LipuJet-P-OB 3554.34.00

3 Pages

-

LipuJet-P-OB 3553.34.00

3 Pages

-

LipuJet-P-OB 3552.34.00

3 Pages

-

LipuJet-P-OB 3551.34.00

3 Pages

-

Lipumax P-D Intermedi

52 Pages

-

Lipumax P-DM High Manual Co

52 Pages

-

Lipumax P-B Basic

52 Pages

-

Pipe®

36 Pages

-

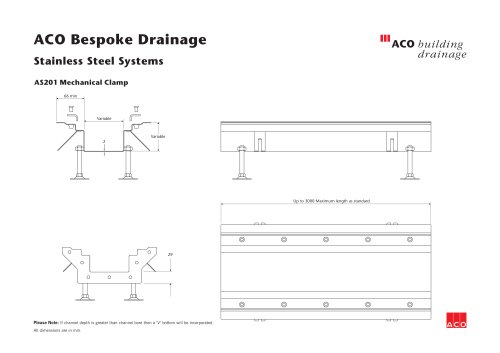

AS2001 Tray Channel

20 Pages

-

Rainwater Outlets

32 Pages

-

Mobile separators

4 Pages

-

Junior® Backflow

2 Pages

-

Quatrix® without Chamber

2 Pages

-

uatrix® with Chamber

2 Pages

-

riplex® with Chamber

2 Pages

-

AS701 Upstand

2 Pages

-

AS801 Micro Channel

2 Pages

-

AS901 Hi Load

2 Pages

-

Shower Gratings

2 Pages

-

BD June Event Summary Binder

185 Pages

-

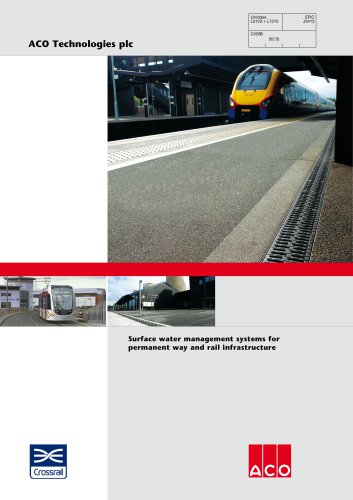

Railway Brochure

20 Pages

-

Grease Separators

52 Pages

-

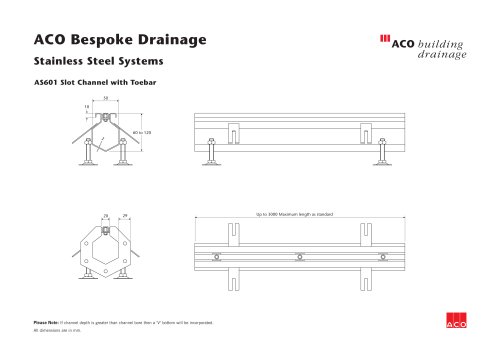

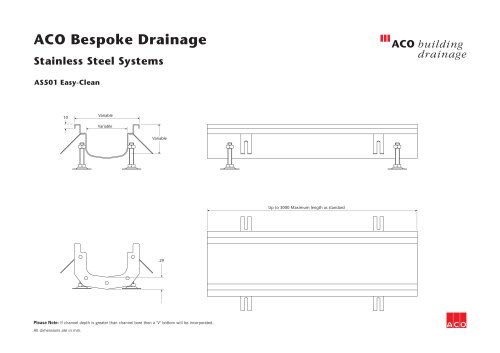

AS501

2 Pages

-

AS401

2 Pages

-

AS301

2 Pages

-

AS201

2 Pages

-

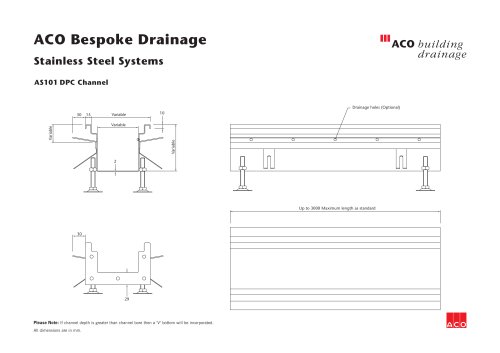

AS101

2 Pages

-

Radius Channel

2 Pages

-

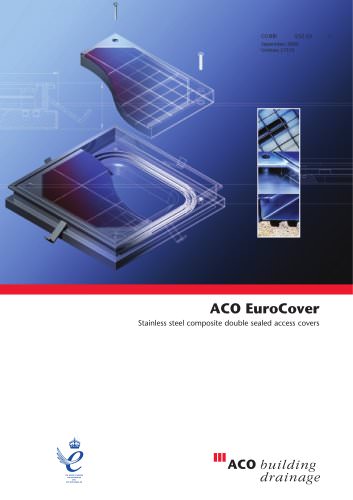

Eurocover Access Cover

8 Pages

-

Alucover Access Cover

2 Pages

-

FreeDeck

20 Pages

-

Pipe®

60 Pages

-

Stainless Steel Gully Systems

56 Pages

-

Bath-to-Wetroom Adaptor

2 Pages

-

Walk-in Solution

18 Pages

-

Easyflow

16 Pages

-

Shower Gullies

35 Pages

-

Shower Channels

48 Pages

-

Wetroom Former

2 Pages