Website:

3D|CORE GmbH & Co. KG

Website:

3D|CORE GmbH & Co. KG

Catalog excerpts

FABRIC FABRIC 3D|CORE™ FOAM CORE THE LIGHTWEIGHT SOLUTION WITH A SYSTEM! 3D|CORE™ is a patented honeycomb structure that is inserted into a closed-cell PET or XPS foam core. The honeycombs, which are connected to each other via small foam bridges, run through the entire foam core and enable a high flexibility of the core. Between the individual honeycomb foam bodies are cavities that are filled with a matrix of synthetic resin and support the filling process as an integrated flow aid. ONCE THE MATRIX HAS CURED: The foam core retains its shape and develops excellent technical properties The...

Open the catalog to page 2

YOUR BENEFITS 3D|CORE™ FOAM CORE THE 3D|CORE™ STRUCTURE GIVES TECHNICAL RIGID FOAM CORES MAXIMUM FLEXIBILITY: Three-dimensional formability for the production of convex and concave components Easy handling without pressure and heat No additional processing steps required (no intermediate vacuum as 3D|CORE™ foam cores adhere to the mould) Increased drapability (adaptation to complex shapes and contours) THE 3D|CORE™ STRUCTURE ACTS AS AN INTEGRATED FILLING AND VENTING SYSTEM: The 3D|CORE™ honeycomb structure acts as an integrated flow aid and supports the filling process with a liquid matrix...

Open the catalog to page 3

YOUR BENEFITS FILLED 3D|CORE™ STRUCTURE THE RESIN STRUCTURE AROUND THE INDIVIDUAL HONEYCOMB FOAM BODIES HOLDS THE LAMINATE TOGETHER: Long-term resistance even under permanent load (delamination of the surface layers and component failure are prevented) High damage tolerance of the final component ONCE THE RESIN HAS CURED, THE COMPONENT RETAINS ITS SHAPE: The honeycomb foam bodies follow the shaping contour and do not stick out The component remains dimensionally stable after being processed

Open the catalog to page 4

YOUR BENEFITS FILLED 3D|CORE™ STRUCTURE THE RESIN AROUND THE 3D|CORE™ STRUCTURE ACTS AS A DOUBLET-BEAM AND ENABLES EXCELLENT MECHANICAL PROPERTIES: Improved shear and compression properties compared to standard foam cores (800% higher compression modulus, 300% higher shear modulus) Increased strength and stiffness compared to standard foam cores (500% higher flexural strength) Optimal performance to weight ratio Optimal absorption and transmission of forces (in-plane compression load significantly better than regular systems) The reinforced 3D|CORE™ high-performance foam cores replace...

Open the catalog to page 5

Component weight Material usage YOUR BENEFITS 3D|CORE™ SYSTEM 3D|CORE™ ENABLES SIGNIFICANT SAVINGS COMPARED TO STANDARD FOAM CORES AND MONOLITHIC STRUCTURES: Material savings: significantly less consumables (no flow aid, peel ply, fleece, perforated film and spray adhesive), less resin consumption (no additional resin for consumables), less fibres Weight saving: the closed-cell 3D|CORE™ foam and its honeycomb structure ensure calculable resin and fibre consumption (no additional resin and fibres without technical benefit) Cost saving: resulting from less weight and material and the immense...

Open the catalog to page 6

YOUR BENEFITS 3D|CORE™ SYSTEM 3D|CORE™ SUPPORTS YOU IN ACHIEVING YOUR CO2 TARGETS: Sustainable manufacturing process (savings of consumables) Recycled and recyclable core materials Minimization of material consumption (no extra weight without technical benefit) DID YOU KNOW? 300 m² of our 3D|CORE™ PET GR in 20 mm thickness save 969 kg CO2. That is equivalent to one passenger flying from Frankfurt to New York

Open the catalog to page 7

HEXAGON STRUCTURE Improvement of the 3D|CORE™ HX structure compared to standard foam cores: Technical properties of the core by 100%, flexibility by 100% and more Peel strength of the fibre layers by 100% Available in the XPS and PET foam. RHOMBUS STRUCTURE Improvement of the 3D|CORE™ RB structure compared to standard foam cores: Technical properties approx. 200%, flexibility approx. 200% and more Peel strength of the fibre layers about 150% Available in the XPS and PET foam. DELTA STRUCTURE Improvement of the 3D|CORE™ DT structure compared to standard foam cores: Flexibility by more than...

Open the catalog to page 8

PRODUCTION CERTIFICATION

Open the catalog to page 9All 3D|CORE GmbH & Co. KG catalogs and technical brochures

-

TDS 3D|CORE™ XPS

2 Pages

-

TDS 3D|CORE™ PET GR

2 Pages

-

TDS 3D|CORE™ PET FR

2 Pages

-

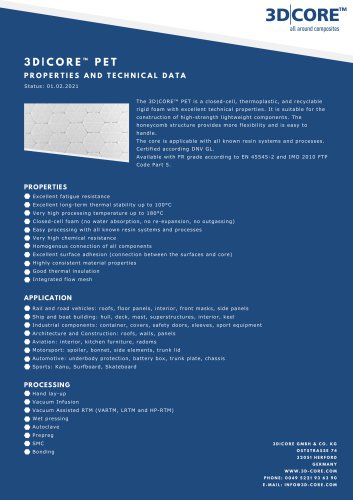

TDS 3D|CORE™ PET

2 Pages

-

3D|CORE™ Markets

11 Pages

-

Fix-in-place™ ASSEMBLY KITS

5 Pages

-

3D|CORE™ PRODUCTS

6 Pages

-

3D|CORE™ SERVICES

9 Pages