カタログの抜粋

Three-component epoxy grout with high chemical resistance for grouting joints with a minimum width of 5 mm CLASSIFICATION IN COMPLIANCE WITH EN 13888 Kerapoxy SP is a reaction resin (R) grout (G) of class RG. WHERE TO USE Acid-resistant grouting of ceramic tile floors wherever there is a need for higher chemical resistance than that obtained from normal epoxy grouting compounds: in particular where resistance to oleic acid and aromatic hydrocarbons is required. Some application examples • Grouting ceramic floors in meat processing factories, particularly in rooms where trimming, cleaning, boning and seasoning operations are carried out, i.e. where the animal fat stays in contact with the grout for extended periods of time and where the installation is subject to frequent washing with hot water under pressure. • Grouting ceramic floors in food preparation factories, particularly in cooking rooms, where the grout is subject to the combined action of oleic acid and high temperatures. • Grouting ceramic floors in areas susceptible to food acids, hot oils, animal fats and similar food processing operations. TECHNICAL CHARACTERISTICS Kerapoxy SP is a three-component mortar consisting of a liquid epoxy resin, a specially formulated amine-based hardener and a mineral filler composed of graded silica sand, specially proportioned, according to a formula developed in the MAPEI Research Laboratories, to obtain the greatest grout density. Without undergoing noticeable shrinkage, Kerapoxy SP hardens quickly by chemical reaction alone, and becomes a product whose chemical and mechanical resistance is higher than those of normal epoxy grouting compounds (see table 1). Kerapoxy SP is only available in beige. RECOMMENDATIONS • Kerapoxy SP must not be used for flexible expansion joints or for joints that are subject to movement. Use a MAPEI flexible sealant, for example Mapesil AC, Mapeflex PU21, Mapeflex PU20. • Perfect adhesion cannot be guaranteed if Kerapoxy SP is used for grouting tiles with wet edges or those contaminated with cement, dust, oil, grease, etc. • Do not add water or solvent to Kerapoxy SP to increase workability. • Always mix the three components with scales: a wrong catalyst ratio is detrimental to the hardening process. • Kerapoxy SP has a higher modulus of elasticity than Kerapoxy (15,000 N/mm2 against 1,500 N/mm2); it is therefore essential to provide more frequent expansion joints, certainly at least every 4-5 metres. APPLICATION PROCEDURE Preparing the joints The joints must be dry, clean, free of dust and empty for at least 2/3 of the depth of the tiles. Any excess adhesive or grout must be cleaned while still fresh. Before grouting make sure the fixing mortar or the adhesive has released most of its moisture. Kerapoxy SP is not affected by surface moisture but the joints should not be wet during grouting. Preparing the mix Mix the two liquid components first, i.e. the resin (component A) and the hardener (component B) using a suitable mixing machine. The quantities are already in the correct proportions, so mistakes in mixing should not be made. Then add the powder (component C) and keep stirring until a smooth paste with the consistency of damp sand is obtained. Apply the mortar immediately after mixing; the mix has a limited working time (20 minutes). [sche1] 142 Inglese (KERAPOXY SP) (03.01.2006 - 4ª Bozza/Ciano Digitale/Stampa)

カタログの1ページ目を開く

Filling the joints with pointing trowel Kerapoxy SP should be applied with a 12 cm pointing trowel (see photo). Fill the joints completely and press in the paste thoroughly. The excess Kerapoxy SP must be removed from the joints. Room and floor temperature have a big influence on the setting, working and cleaning In contrast to what happens with traditional epoxy grouting compounds, a fall in temperature from +25/30°C to +5/10°C does not make the application of Kerapoxy SP more difficult. However pot life, working time and cleaning time of Kerapoxy SP varies greatly between about 50 minutes...

カタログの2ページ目を開く

TECHNICAL DATA (typical values) In compliance with: PRODUCT IDENTITY component A viscous liquid Brookfield Viscosity (mPa•s): 24 months in original packing. Store at a temperature of at least +10°C to avoid crystallization of the liquid products which, however, can be reversed by warming Hazard classification according to EC 99/45: irritant corrosive none hazardous for the environment Before using refer to the “Safety instructions for the preparation and application” paragraph and the information on the packing and Safety Data Sheet Customs class: Removing the excess Kerapoxy SP with a...

カタログの3ページ目を開く

TAB. 2 CONSUMPTION TYPE OF TILE Impervious tiles Quarry and impervious tiles Quarry and impervious tiles Quarry and impervious tiles WORKABILITY IN RELATION TO TEMPERATURE (minutes) Kerapoxy SP component A is dangerous to aquatic organisms - avoid release to the environment. WARNING Although the technical details and recommendations contained in this product data sheet correspond to the best of our knowledge and experience, all the above information must, in every case, be taken as merely indicative and subject to confirmation after long-term practical applications; for this reason, anyone...

カタログの4ページ目を開くMAPEIのすべてのカタログと技術パンフレット

-

GENERAL CATALOGUE_2024

224 ページ

-

KERAQUICK S1

4 ページ

-

ADESILEX P9 EXPRESS

4 ページ

-

PLANITOP 100

4 ページ

-

COLORITE PERFORMANCE

6 ページ

-

ULTRATOP LOFT F

6 ページ

-

ULTRACOLOR PLUS

6 ページ

-

keracolorff

4 ページ

-

ISOLASTIC

4 ページ

-

KERAPOXY

6 ページ

-

mapebandpe120

2 ページ

-

PRIMER G

4 ページ

-

KERAFLEX MAXI S1

4 ページ

-

KERABOND T

4 ページ

-

ADESILEX P4

4 ページ

-

MAPESIL LM

4 ページ

-

MAPECOAT I 600W

4 ページ

-

WALLGARD BARRIER

4 ページ

-

MAPECURE SRA

4 ページ

-

LAMPOCEM

4 ページ

-

365-epojetlv-gb

4 ページ

-

Thermal insulation

60 ページ

-

ULTRAFLEX S2 QUICK

4 ページ

-

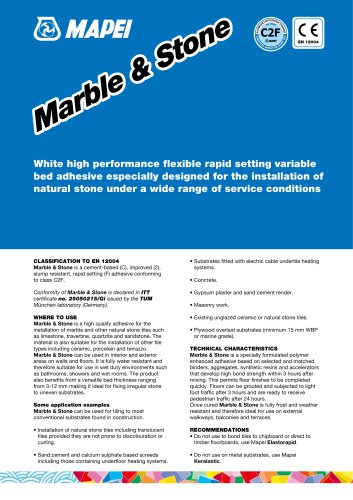

MARBLE & STONE

4 ページ

-

LIGNOBOND

4 ページ

-

ULTRABOND P902 2K

4 ページ

-

ULTRABOND P913 2K

4 ページ

-

ULTRABOND P990 1K

4 ページ

-

ULTRABOND S997 1K

4 ページ

-

FIBERPLAN

4 ページ

-

LATEX PLUS

4 ページ

-

NIVORAPID

4 ページ

-

TOPCEM

4 ページ

-

SILWOOD

4 ページ

-

MAPEPROOF ESM

4 ページ

-

TRIBLOCK P

4 ページ

-

ULTRACOAT OIL

2 ページ

-

MAPEPLAST LA

4 ページ

-

MAPETHERM AR1

4 ページ

-

MAPETHERM NET

2 ページ

-

General catalogue 2017

292 ページ

-

FastTrack

24 ページ

-

Ultralite range

8 ページ

-

Keracolor Flex

2 ページ

-

Kerapoxy CQ

2 ページ

-

Ceramic Pocket Guide

82 ページ

-

MAPELASTIC TURBO

2 ページ

-

PURTOP LINE

2 ページ

-

AQUAFLEX ROOF

2 ページ

-

AQUADEFENSE

2 ページ

-

Keracolor GG

6 ページ

-

Granirapid

4 ページ

-

MAPEFLEX PU30

4 ページ

-

Marble and Stone

4 ページ

-

Concrete Admixtures

30 ページ

-

RE-CON Zero

6 ページ

-

Realtà Mapei 43

84 ページ

-

Realtà Mapei 44

84 ページ

-

Realtà Mapei 45

84 ページ

-

Mapei et vous 40

36 ページ

-

Realtà Mpaei 46

116 ページ

-

Realtà Mapei 47

84 ページ

-

Realtà Mapei 48

84 ページ

-

Realata Mapei 49

84 ページ

-

Realtà MAPEI

84 ページ

-

Resilient Adhesives

16 ページ

-

Ceramic Pocket Guide

41 ページ

-

MAPEFER 1K

4 ページ

-

ULTRATOP INDUSTRIAL

4 ページ

-

ADESILEX PA

4 ページ

-

ULTRABOND P980 1K

4 ページ

-

ECO PRIM GRIP

4 ページ

-

MAPEPRIM SP

4 ページ

-

KERAFLEX

4 ページ

-

ELASTORAPID

4 ページ

-

ADESILEX P9

4 ページ

-

ADESILEX P10

4 ページ

-

MAPEFLEX PU45

4 ページ

-

FUGOLASTIC

4 ページ

-

MAPESILENT PANEL

4 ページ

-

realta mapei

84 ページ

カタログアーカイブ

-

General Catalogue

291 ページ