16LJ Single-Effect, Low Temperature Hot Water Hermetic Absorption Liquid Chiller, 75 to 525 Nominal Tons

1 /

32ページ

カタログの抜粋

Product Data Carrier SAMYO 16LJ Single-Effect, Low Temperature Hot Water Hermetic Absorption Liquid Chiller 75 to 525 Nominal Tons Carrier-Sanyo's 16LJ single-effect hermetic absorption liquid chiller is an efficient and functional alternative to traditional electric driven chillers. The 16LJ absorption chiller uses low temperature hot water as its energy source; as it eliminates the need for high cost electricity, it may qualify for financial incentives as a gas cooling product. The 16LJ absorption chiller offers functional flexibility in a variety of installations: • no CFCs; environmentally sound • single stage design for simple, dependable operation • high reliability with few moving parts • nominal coefficient of performance (COP) of .70 • quiet, vibration-free operation • Direct Digital Controls (DDC) for optimum chiller performance Features/Benefits Single-effect absorption cycle provides efficient, economical water chilling with minimal use of electricity. Cost-effective cooling Alternative-energy chiller — The 16LJ chiller is a solution for building owners who want to avoid high operating costs associated with electric-driven chillers. Powered by low temperature hot water, the Carrier-Sanyo 16LJ absorption chiller reduces or eliminates electric demand and/or ratchet charges while allowing the owner to take advantage of gas cooling incentives when offered by local utility companies. Copyright 2005 Carrier Corporation

カタログの1ページ目を開く

Features/Benefits (cont) Simple, reliable operation — The 16LJ chiller’s single generator provides one stage of solution reconcentration, which makes the 16LJ chiller one of the most basic cycles currently available. The 16LJ chiller’s simple design, in addition to its other quality features, equates to inherently high reliability. Few moving parts and simple, dependable operation reduce downtime, as well as service and maintenance costs. Exceptional efficiency — The 16LJ chiller offers full-load COPs of .70 at standard ARI (Air Conditioning and Refrigeration Institute) operating...

カタログの2ページ目を開く

The Carrier-Sanyo microprocessor PID (proportional, integral, derivative) control system surpasses proportional only control systems by maintaining precise leaving chilled water temperature versus actual set point. The PID controls surpass proportional only controls in their ability to control the machine and narrow temperature variations. The 16LJ chiller control system also incorporates the ability to control the chilled water and cooling water pumps automatically. During shutdown these pumps are sequenced to ensure a complete dilution cycle, thus providing protection from solution...

カタログの3ページ目を開く

corrosion, lithium bromide solution crystallization, and/or reduction of chiller capacity. The Carrier-Sanyo purge system protects against these potential hazards by operating continuously during machine operation. How the purge system operates — During chiller operation, any noncondensables that are present tend to accumulate in the absorber section, which operates at the lowest pressure internal to the machine. A slipstream of lithium bromide solution flows through an eductor from the absorbent pump discharge. This process creates suction, which draws the noncondensables from the...

カタログの4ページ目を開く

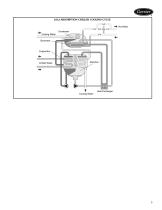

16LJ ABSORPTION CHILLER COOLING CYCLE Hot Water Condenser Cooling Water Generator Chilled Water Heat Exchanger Cooling Water

カタログの5ページ目を開く

Unit Size - Nominal Tons LJ - Single Effect, Low Temperature Hot Water (1-Stage) ^ Options and accessories ITEM

カタログの6ページ目を開く

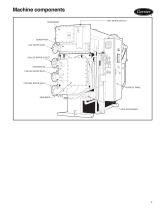

Machine components CONDENSER GENERATOR HOT WATER INLET CHILLED WATER OUTLET EVAPORATOR CHILLED WATER INLET COOLING WATER INLET CONTROL PANEL HEAT EXCHANGER

カタログの7ページ目を開く

Physical data UNIT 16LJ

カタログの8ページ目を開く

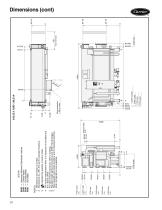

indicates the position of anchor bolts. 4. For routine maintenance allow 3 ft clearance on all sides and 8 in. above chiller. 5. For tube removal clearance, refer to drawing. 6. Standard water piping connections are ANSI 150 lb flanges. 7. Pass quantity and nozzle locations are for standard machine; other configurations are available. NOTES: 1. Dimensions are shown in inches. 2. Dimensions (L), (W), (H) are for standard machine. American National Standards Institute Chilled Water Cooling Water Hot Water Wire connection 1-3/8 in. hole

カタログの9ページ目を開く

American National Standards Institute Chilled Water Cooling Water Hot Water indicates the position of anchor bolts. 4. For routine maintenance allow 3 ft clearance on all sides and 8 in. above chiller. 5. For tube removal clearance, refer to drawing. 6. Standard water piping connections are ANSI 150 lb flanges. 7. Pass quantity and nozzle locations are for standard machine; other configurations are available. NOTES: 1. Dimensions are shown in inches. 2. Dimensions (L), (W), (H) are for standard machine. PURGE PUMP Dimensions (cont)

カタログの10ページ目を開く

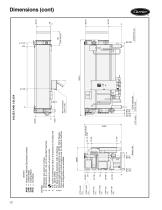

American National Standards Institute Chilled Water Cooling Water Hot Water indicates the position of anchor bolts. 4. For routine maintenance allow 3 ft clearance on all sides and 8 in. above chiller. 5. For tube removal clearance, refer to drawing. 6. Standard water piping connections are ANSI 150 lb flanges. 7. Pass quantity and nozzle locations are for standard machine; other configurations are available. NOTES: 1. Dimensions are shown in inches. 2. Dimensions (L), (W), (H) are for standard machine. PURGE PUMP

カタログの11ページ目を開く

American National Standards Institute Chilled Water Cooling Water Hot Water indicates the position of anchor bolts. 4. For routine maintenance allow 3 ft clearance on all sides and 8 in. above chiller. 5. For tube removal clearance, refer to drawing. 6. Standard water piping connections are ANSI 150 lb flanges. 7. Pass quantity and nozzle locations are for standard machine; other configurations are available. NOTES: 1. Dimensions are shown in inches. 2. Dimensions (L), (W), (H) are for standard machine. Dimensions (cont)

カタログの12ページ目を開く

American National Standards Institute Chilled Water Cooling Water Hot Water indicates the position of anchor bolts. 4. For routine maintenance allow 3 ft clearance on all sides and 8 in. above chiller. 5. For tube removal clearance, refer to drawing. 6. Standard water piping connections are ANSI 150 lb flanges. 7. Pass quantity and nozzle locations are for standard machine; other configurations are available. NOTES: 1. Dimensions are shown in inches. 2. Dimensions (L), (W), (H) are for standard machine.

カタログの13ページ目を開くCARRIER commercialのすべてのカタログと技術パンフレット

-

40UV-UH-14SI

32 ページ

-

42B-6SI

24 ページ

-

A WORLD OF COMFORT PRINT

10 ページ

-

A WORLD OF COMFORT

20 ページ

-

A World of Comfort

2 ページ

-

Carrier-Catalogue-2018-2019

940 ページ

-

19DV

32 ページ

-

30XA

136 ページ

-

30RAP

104 ページ

-

2019 Carrier Ductless

88 ページ

-

Carrier VRF

44 ページ

-

Roomtop® 50AH036-072

24 ページ

-

OMNIZONE™ 50BV020-064

64 ページ

-

A World of Comfort

2 ページ

-

ComfortVIEW 3

6 ページ

-

VVT Zoning System

8 ページ

-

Comfort? Series

2 ページ

-

GEMINI? 38AKS028-044

40 ページ

カタログアーカイブ

-

ROOMAIR CONDITIONERS

6 ページ