Website:

Tower Tank Systems

Website:

Tower Tank Systems

Catalog excerpts

Intelligent Low Energy Sewage Treatment System This treatment plant draws upon the advantages of normal aeration systems but with the benefits of a sequence batch reactor (SBR) to reduce energy use. It is easy to install, simple and trouble free to operate; and unlike most treatment systems does not need to run constantly. The plant is ideal for domestic and light commercial applications and available in three sizes up to a unit for 10 occupants. Quiet & Efficient The use of a piston compressor, housed in a waterproof capsule below the access cover, makes operation of the plant virtually undetectable to the ear. The piston compressor is close to where the air is required so less energy is used. Intelligent By using batch processing, the compressor only operates when needed to save energy. A level sensor can be fitted to automatically activate a “holiday mode” program. Alarm feature fitted as standard. Extremely reliable The piston compressor was originally developed for life saving medical applications. By housing it in the access shaft it is protected from extreme temperature fluctuation which prolongs the operating life of the compressor. The shallow dig tank makes the plant easy to install and visually discrete. Concrete is not required for this strong 8mm thick, ribbed polyethylene tank even in poor ground conditions. Plant includes integrated sample chamber. Full EN 12556-3 Certification. Accepted by the EA for exception from consent to discharge under the new EPP2 scheme. Cost effective The unit only needs to oxygenate the water when a batch of effluent is discharged into the reactor chamber. This efficient processing means the operating cost is only £8-10 per person per year.

Open the catalog to page 1

Treatment Plant: Power Supply: Single Phase Invert Depth: 660-800 mm (110mm Soil Pipe) Contact us should you require the treatment plant to be installed at a lower depth Control Panel: 200 x 120 x 60mm (w x h x d) The Control panel must not be situated more that 10 meters away from the tank. Power is to the control panel and not the plant. An air intake pipe is supplied 50mm dia. stainless steel, with 3.5m hose, must be installed with 50 cm hose in the tank shaft. Hose extension available. To Land or Stream (with EA consent or EPP2 exemption). Check porosity of the ground by doing...

Open the catalog to page 2All Tower Tank Systems catalogs and technical brochures

-

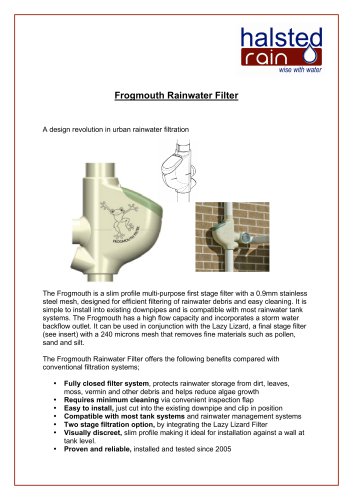

Frogmouth Rainwater Filter

2 Pages

-

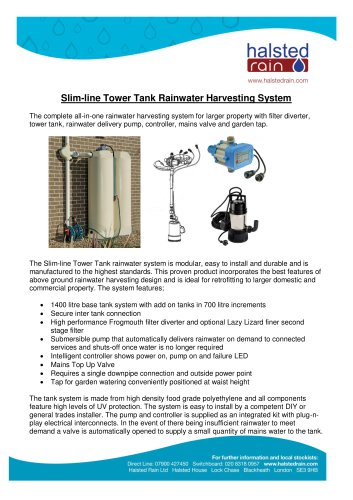

Slim - line Tower Tank

2 Pages

-

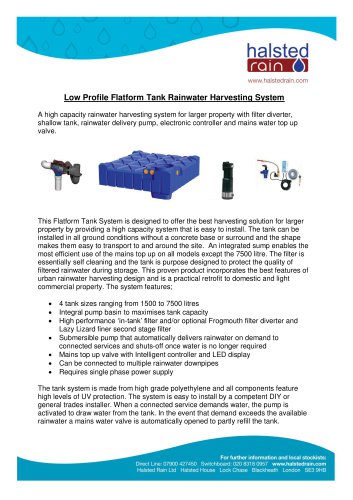

Flatform Tank

2 Pages