Website:

TATA STEEL

Website:

TATA STEEL

Group: TATA Steel

Catalog excerpts

TATA STEEL TATA RQT® technical guide High strength quenched and tempered structural steel.

Open the catalog to page 1

Contents 3 About RQT 3 Tata Steel 4 RQT data 5 RQT 501 dimensions 6 RQT 601 and RQT 701 dimensions 7 RQT 901 dimensions 8 Fabrication guide 9-11 Welding guide

Open the catalog to page 2

RQT® High strength quenched and tempered structural steel. The RQT range of steels have been developed for applications where high strength and outstanding toughness are necessary, such as mining and quarrying, process industry, material handling, construction and earthmoving. This technical guide provides data for our range of RQT steels. This guide provides all the essential operating parameters for the use of RQT steel in the manufacturing process. Tata Steel works in partnership with customers, tailoring products and services to suit their applications, delivering value improvement...

Open the catalog to page 3

RQT® Tata Steel offer a range of RQT grades designed for high performance in service and ease of fabrication. Close control of chemistry ensures RQT steels are readily weldable in accordance with the guidelines in this brochure. Table 1. Chemical analysis Table 2. Carbon equivalent Testing in accordance with EN ISO 6892, EN ISO 148-1 and EN ISO 6506. Table 3. Mechanical properties Thickness (mm) Min. yield Tensile strength strength (MPa) (MPa) Min. elongation on 50mm gauge length (%) Min. average impact energy* (J at -40°C) Min. individual impact energy* (J at -40°C) Testing in accordance...

Open the catalog to page 4

Size availability guide The information in this table must be read in conjunction with the explanatory notes at the bottom of page 7. Figures within the table are maximum lengths in metres.

Open the catalog to page 5

Size availability guide The information in this table must be read in conjunction with the explanatory notes at the bottom of the page 7. Figures within the table are maximum lengths in metres. 110 Please contact us with your requirements 120 Please contact us with your requirements 130 Please contact us with your requirements

Open the catalog to page 6

Size availability guide The information in this table must be read in conjunction with the explanatory notes at the bottom of this page. Figures within the table are maximum lengths in metres. Notes on size tables There will be occasions when sizes and grades may be manufactured which are not shown in the individual grade tables. As a guide to the available plate sizes for an intermediate gauge (e.g. 18mm), please use the nearest gauge shown in the individual grade tables (i.e. 20mm). Plate widths up to 3200mm wide are available on request. Please contact us with your specific requirements....

Open the catalog to page 7

RQT 501 can be cold sheared. The maximum gauge that can be handled will depend on the power available in the shear unit and the shear blade material. For smaller shears the maximum thickness should be reduced dependant on the grade.Table 4 lists the reduction in thickness required compared to S355JR grade material. Table 4: Shearing thickness reduction compared to S355JR material Flame cutting RQT steels can be cut satisfactorily using conventional oxy-fuel gas practices, without the need for preheat, provided cutting procedures are selected with consideration of the plate thickness and the...

Open the catalog to page 8

WELDING GUIDE The Roller Quench and Tempered series of steels combine high yield and tensile strengths with good notch toughness, they have excellent weldability, and high integrity welded joints can be made in all of the RQT grades. The following are important factors when making welds in RQT steels. Joint Design Joint design and good workmanship are needed to take advantage of the high strength of Q&T steels and to optimize the serviceability of weldments made in them. Abrupt changes in cross section or stress raisers in regions of high stress are detrimental in very high strength steels....

Open the catalog to page 9

Hydrogen cracking. As with all higher strength steels, RQT steels can be susceptible to hydrogen cracking, also known as'cold cracking'and'delayed cracking'. The chart below shows that as carbon and carbon equivalent increases then the greater the possibility of cracking occurring. Carbon equivalent Cracking is unlikely but may occur with high hydrogen or high restraint. Cracking could occur. Prevention is based on controlling the cooling rate to stop HAZ hardness reaching a critical value.This could be achieved by judicious use of welding heat input and/or preheat Risk of cracking. Low...

Open the catalog to page 10

Combined thickness for preheat Refer to preheat tables on pages 4 to 7 Fillet weld Combined thickness = t1 + t2 + t3 In accordance with EN1011-2, Preheat to extend 75mm either side of the weld centreline Butt weld Combined thickness = t1 + t2 In accordance with EN1011-2, Preheat to extend 75mm either side of the weld centreline Welding consumables Welding consumables for welding processes commonly used in fabrication are available with matching strengths for the RQT series of steel. Your consumable supplier will be able to recommend a suitable electrode.

Open the catalog to page 11

RQT is a registered trademark of Tata Steel. While care has been taken to ensure that the information contained in this brochure is accurate, neither Tata Steel Europe Limited nor its subsidiaries accept responsibility or liability for errors or information which is found to be misleading. Tata Steel PO Box 1 Brigg Road Scunthorpe North Lincolnshire DN16 1BP United Kingdom Further Information For any enquiries regarding product application, metallurgy or mechanical properties please contact our Technical Advisory Service +44 (0) 1724 402106 or email: plates.technical@tatasteel.com T +44 (0)...

Open the catalog to page 12All TATA STEEL catalogs and technical brochures

-

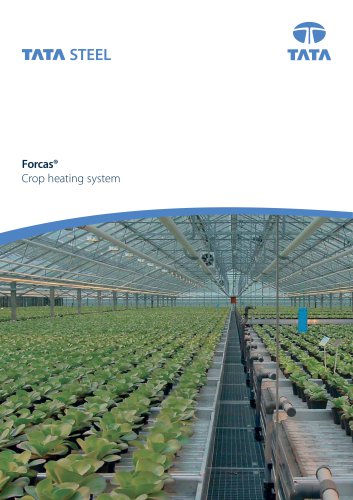

Forcas

8 Pages

-

Colorcoat®SDP 35

2 Pages

-

Colorcoat SDP 50

2 Pages

-

Colorcoat Aquatite

6 Pages

-

Colorcoat_Agriculture

16 Pages

-

Colorcoat Urban

12 Pages

-

Confidex® Home

1 Pages

-

Colorcoat GP

2 Pages

-

Colorcoat PVDF

2 Pages

-

Colorcoat PE 25

2 Pages

-

Colorcoat Prisma® colour card

11 Pages

-

Strongbox brochure

12 Pages

-

Hybox® 355

16 Pages

-

ComFlor manual

92 Pages

-

Colorcoat®SDP 35 - RWG

2 Pages

-

Colorcoat® PE 15

2 Pages

-

ColorcoatPrisma®

11 Pages

-

Trisomet®

48 Pages

-

Kalzip® FC rainscreen

24 Pages

-

Plates and Profiling Slabs

8 Pages

-

Trench_brochure_2010

8 Pages

-

Cold Formed Sections Brochure

36 Pages

-

Kalzip FC rainscreen system

20 Pages

-

Kalzip FC façade system

8 Pages

-

RoofDek

24 Pages

-

The surest way is steel

12 Pages