Website:

Lime Technology

Website:

Lime Technology

Catalog excerpts

Sustainable building innovation Tradicaf Better-than-zero carbon

Open the catalog to page 1

Thermal performance • Hemcrete® – the science 1. 2. 3. 4. 5. 6. 7. 8. Thermal conductivity (U values) Thermal mass Thermal inertia (diffusivity) Amplitude suppression and phase displacement Air-tightness Thermal bridging and Y values SAP & CSH Summary – – – – Lime Technology offices Adnams brewery warehouse Wine Society warehouse Private houses • Hemcrete® – in practice

Open the catalog to page 2

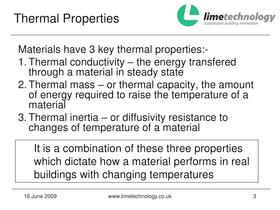

Thermal Properties Materials have 3 key thermal properties:1. Thermal conductivity – the energy transfered through a material in steady state 2. Thermal mass – or thermal capacity, the amount of energy required to raise the temperature of a material 3. Thermal inertia – or diffusivity resistance to changes of temperature of a material It is a combination of these three properties which dictate how a material performs in real buildings with changing temperatures 16 June 2009 www.limetechnology.co.uk 3

Open the catalog to page 3

1. Thermal conductivity • Is the rate of energy transfer under a constant temperature difference in a steady state, where temperatures inside and outside the building remain constant • It is a simple but crude measure of thermal efficiency as temperatures are always changing • To measure how buildings perform in real life under changing temperatures other measures such as thermal capacity and inertia are needed 16 June 2009 www.limetechnology.co.uk 4

Open the catalog to page 4

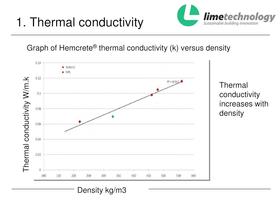

1. Thermal conductivity Thermal conductivity W/m.k Graph of Hemcrete® thermal conductivity (k) versus density Thermal conductivity increases with density Density kg/m3

Open the catalog to page 6

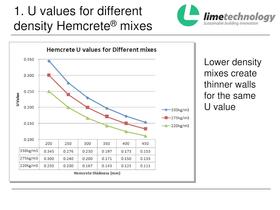

Sustainable building innovation Hemcrete U values for Different mixes

Open the catalog to page 7

2. Thermal inertia (diffusivity) Material • Hemcrete® has a low thermal diffusivity compared to other building materials • This gives it a high thermal inertia and means it is slow to change temperature and slow to reach steady state • This slows heat transfer down whilst the material is in the process of reaching steady state (most of the time) Diffusivity (m2/s x 10-7) Hemcrete® 1.4 Wood 1.6 AAC 2.3 Clay brick 4.1 Polyuerethane insulation 7.9 Concrete 8.5 Mineral fibre 14.4 Expanded polystyrene 18.4

Open the catalog to page 8

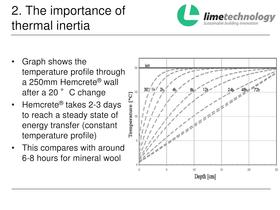

2. The importance of thermal inertia • Graph shows the temperature profile through a 250mm Hemcrete® wall after a 20 °C change • Hemcrete® takes 2-3 days to reach a steady state of energy transfer (constant temperature profile) • This compares with around 6-8 hours for mineral wool

Open the catalog to page 9

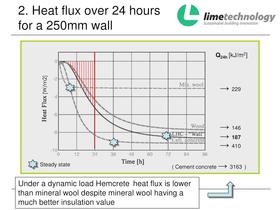

2. Heat flux over 24 hours for a 250mm wall Q24h [kJ/m2] → 229 → 146 → 187 → 410 Steady state ( Cement concrete Under a dynamic load Hemcrete heat flux is lower than mineral wool despite mineral wool having a much better insulation value → 3163 )

Open the catalog to page 10

2. Effective U-value of Hemcrete® • • • • • • 187,000 J/m2 lost in 24 hours 1W = 1J/s There are 86,400 seconds in 24 hours The temperature difference was 20oC So the real heat loss was only 0.11W/m2k Theoretical U-value is 0.29W/m2k In this case Hemcrete® has transferred almost 3 times less heat than the steady state model would have estimated

Open the catalog to page 11

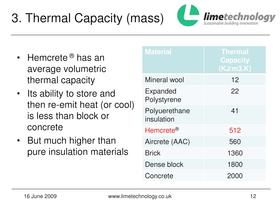

3. Thermal Capacity (mass) • Hemcrete ® has an average volumetric thermal capacity • Its ability to store and then re-emit heat (or cool) is less than block or concrete • But much higher than pure insulation materials Material Thermal Capacity (KJ/m3.K) 12 Expanded Polystyrene 22 Polyuerethane insulation 41 Hemcrete® 512 Aircrete (AAC) 560 Brick 1360 Dense block 1800 Concrete 16 June 2009 Mineral wool 2000 www.limetechnology.co.uk 12

Open the catalog to page 12

4. Combined effects • The combined effects of thermal inertia and thermal mass slow the temperature change down inside the building • They also delay the peak internal temperature by a number of hours • The optimum delay is 12-15 hours so that peak internal temperature occurs at night • Shorter delays cause summer overheating in the afternoons/early evening – a characteristic of lightweight buildings. 16 June 2009 www.limetechnology.co.uk 13

Open the catalog to page 13

4. Amplitude suppression and phase displacement • A 250mm Hemcrete® wall reduces external temperature changes by 98% • A day/night change from 0 to 20oC over 24hrs is almost completely dampened to less than +/- 1oC • Examples such as the Wine Society and Adnams have proved this in operation • Any temperature change that does occur is delayed so that heating occurs at night and cooling during the day

Open the catalog to page 14

4. Amplitude suppression with a 20°C external temperature change External temperature represents the normal day/night 24 hour cycle Max external temperature Max internal temperature

Open the catalog to page 15

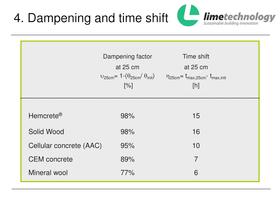

4. Dampening and time shift Dampening factor Time shift at 25 cm 25cm= 1-(25cm/ init) at 25 cm 25cm= tmax,25cm- tmax,init [%] [h] ______________________________________________ Hemcrete® 98% 15 Solid Wood 98% 16 Cellular concrete (AAC) 95% 10 CEM concrete 89% 7 Mineral wool 77% 6

Open the catalog to page 16

4. Dampening and time shift • AAC, Hemcrete® and solid wood each have a beneficial mix of thermal capacity and thermal inertia to provide excellent dampening • Concrete has high thermal mass, but no thermal inertia so does not perform as well • Mineral wool and other insulators perform the worst as they have low thermal mass and thermal inertia 16 June 2009 www.limetechnology.co.uk 17

Open the catalog to page 17

5. Air Permeability tests • Hemcrete® is a single homogeneous materials will no layers, membranes, gaps, joints or cavities • This monolithic nature of Hemcrete® makes it inherently air tight • Figures below 2m3/m2/hr at 50 pascals are achievable Project Wine Society Warehouse 4 Approxim Air ate area permeabi lity test achieved 2500m2 3.5 Adnams brewery warehouse 4500m2 3.1 Lime Technology’s office 250m2 2.3 Crawford private house 150m2 1.5 Renewable House BRE 94m2 2.5

Open the catalog to page 18

6. Thermal bridging • Hemcrete has very few elements that can provide a thermal bridge, no ties, lintels, bridging structure etc • Psi (Ψ) value calculations confirm this • Typical Y values of 0.03 can we used in SAP • Looking to improve the wall/slab junctions to reduce this further to 0.02 16 June 2009 www.limetechnology.co.uk 19

Open the catalog to page 19All Lime Technology catalogs and technical brochures

-

RENDERS & PLASTERS

6 Pages

-

External Wall Insulation

2 Pages

-

Individual homes

6 Pages

-

Sumatec® Earth Blocks

2 Pages

-

Overview of Lime Technology

85 Pages

Archived catalogs

-

Hydraulic Lime Mortars

37 Pages

-

Render & Plaster

14 Pages

-

Multi-pro XS

3 Pages

-

Tradical® Hemcrete® Brochure

2 Pages