Website:

Lime Technology

Website:

Lime Technology

Catalog excerpts

Sustainable building innovation Design Guide Lime Mortar Prepared In Conjunction With CONMRlilTION CONSUllANIi 126 Milton Park, Abingdon, Oxfordshire, Lime products made simple

Open the catalog to page 1

Section 1.0 Introduction Page 1 Section 2.0 Background Page 2 Section 3.0 Materials Page 2 Section 4.0 Design Guidance Page 5 Section 5.0 Construction Page 7 Section 6.0 Summary Page 8 Appendix A Movement in Masonry Page 11 Appendix B Lightweight Steel Framing Page 14 Appendix C Lightweight Steel Framing Page 17

Open the catalog to page 2

1.1 This design guide has been prepared to assist Architects and Structural Engineers with the design of masonry walls constructed with Limetec ®natural hydraulic lime(NHL) mortar produced by Lime Technology Ltd. 1.2 it is assumed that the designer is experienced in the structural design of masonry constructed with cement based mortars to current British Standards and Building Regulations. This guide therefore only covers the differences in design when using lime based mortars instead of cement based ones. 1.3 The designer remains responsible for the design of the masonry wall and must...

Open the catalog to page 3

3.1 Lime Mortars. Lime mortars can either be site mixed or factory mixed. Site mixing requires careful control to ensure consistency between mixes. It also requires selection of a suitable sand as the type of sand can have a considerable impact on the properties of both the wet and hardened mortar. Factory mixing produces a consistent product which has undergone regular testing to ensure that strength and other properties are as specified. Limetec® pre- mixed mortars are produced under the control of a Quality Management System to provide enhanced confidence in the product and traceability...

Open the catalog to page 4

3.3 Strength. Strength of lime mortars is generally specified at 91 days as it gains strength more slowly than cement based mortars which are specified at 28 days age. This slower rate of strength gain should be allowed for when planning follow on operations such as placing beams orfloor units. Single skin brickwork or blockwork has sufficient resistance to vertical loads, but has less resistance to lateral loads at an early age and so consideration needs to be given to this at 3-4 Wall Ties. Wall ties should be stainless steel. Wall ties of Types 1, 2, 3 or4 should be selected on the basis...

Open the catalog to page 6

Lightweight Steel Framing 4.2.1 Lightweight steel framing can be used in place of a blockwork inner leaf with a lime mortared external masonry leaf. This guidance is applicable to designs that meet the following criteria: (i) Masonry panels subject to lateral wind loading and vertical self weight only. (ii) Masonry panels restrained on two or more sides. (iii) Masonry panels tied back to a concrete or steel frame. The steel frame may be fabricated from hot rolled or lightweight cold rolled steei sections. 4.2.2 This guidance relates primarily to clay masonry as there is very little...

Open the catalog to page 7

4.2.12 Movement joints should generally be placed at closer spacing than for other masonry walls constructed with iime mortar. It is recommended that movement joints be spaced at a maximum of 18m for straight walls and 9m from stiff returns. Joints may need to be at closer centres for panels with openings, of large aspect ratio, parapets and large changes in section in accordance with normal practice. 4.2.13 Plasterboard or other board of at least equivalent strength should be screwed onto the inside face of the lightweight steel framing to increase the overall stiffness of the wall panel....

Open the catalog to page 8

To ensure rainwater is shed property and to restrict water being trapped in the bed joints, it is recommended that only flush joints are used. Recessed joints should be avoided as these may lead to premature failure of the mortar. 6.1 Limetec® lime mortars are factory mixed to provide a consistent product, with good characteristics in both the mixed and hardened states. 6.2 Limetec® Moderatley Hydraulic Lime Mortar is appropriate for most uses. For higher degrees of exposure or greater strength use Limetec® Eminently Hydraulic Lime Mortar. 6.3 Lime based mortars are less susceptible to...

Open the catalog to page 9

AKS Ward Ltd, Seacourt Tower, West Way, Oxford, 0X2 OJJ Telephone: 01865 240071, Fax: 01865 248006, e-mail: consult@aksward.com The use of lime-based mortars in new build, NHBC foundation, December 2008 BS 5628-1, Code of Practice for the Use of Masonry - Part 1: Structural use of unreinforced masonry, and part 3: Materials and components, design and workmanship. BS EN 1996-1, Eurocode 6 - Design of masonry structures - Part 1-1: General rules for reinforced and unreinforced masonry structures. Building limes in the United Kingdom by Paul Livesey, Proceedings of the Institution of Civil...

Open the catalog to page 10

Bricks undergo irreversible expansion following firing. This process can take many years to complete although the rate of expansion reduces with time. Concrete blocks and other cement based masonry units such as reconstituted stone undergo shrinkage as they dry our following laying. Again this movement will gradually reduce with time but can continue over many years. Natural Stone generally undergoes very little drying movement following laying. Ail masonry materials expand and shrink due to changes in moisture content and temperature. These movements are reversible and will continue...

Open the catalog to page 11

Significant movement can occur at the corners of buildings where the brickwork expands and slide on the damp proof course (DPC). This can cause the brickwork to over-sai! the wall below DPC which can be unsightly and in extreme cases could cause stability issues. This phenomenon can be seen in long historic masonry buildings such as Victorian terraced housing, although as these building did not have a DPC the brickwork was restrained at ground level but expanded higher up, often causing the end wall to lean outwards. This process can be counteracted by installing bed reinforcement for the...

Open the catalog to page 12

Lightweight Steel Framing 1.1 (Insert brief description of where the SFS is to be used). For the exact location and setting out all SFS Systems and size of masonry panels and openings, reference should be made to the relevant Architect's drawings. 1.2 This performance specification refers to the use of the (Insert manufacturer's name and product reference) Steel Framing System; however, the contractor may propose a similar system by an alternative manufacturer, Any alternative system shall meet this performance specification and be approved by both the Architect and Structural Engineer...

Open the catalog to page 13All Lime Technology catalogs and technical brochures

-

RENDERS & PLASTERS

6 Pages

-

External Wall Insulation

2 Pages

-

Individual homes

6 Pages

-

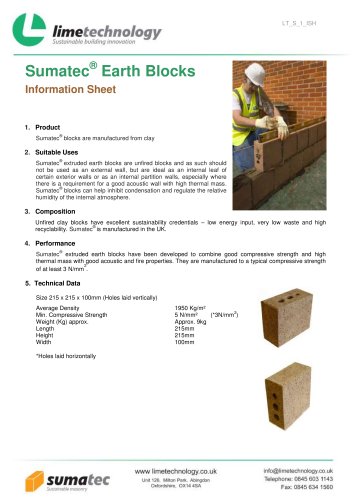

Sumatec® Earth Blocks

2 Pages

-

Overview of Lime Technology

85 Pages

Archived catalogs

-

Hydraulic Lime Mortars

37 Pages

-

Render & Plaster

14 Pages

-

Multi-pro XS

3 Pages

-

Tradical® Hemcrete® Brochure

2 Pages