Website:

Forbo Flooring Systems

Website:

Forbo Flooring Systems

Group: Forbo

Catalog excerpts

Environmental Product DECLARATiON ffedlbo FLOORING SYSTEMS Achieving lower noise pollution is essential to reducing stress and promoting the well-being, comfort and efficiency of people working or learning. The Forbo acoustic project vinyl collection is the result of more than 30 years of acoustic experience and specific industry knowledge which enables us to deliver the “best in class” acoustic vinyl flooring for every application. Forbo was the first flooring manufacturer to publish a complete Life Cycle Assessment (LCA) report verified by CML in 2000. In addition, Forbo is now publishing Environmental Product Declarations (EPD) for all products including full LCA reports. This EPD was developed using recognized flooring Product Category Rules and includes additional information to show the impacts on human health and eco-toxicity. By offering the complete story we hope that our stakeholders will be able to use this document as a tool that will translate the environmental performance of acoustic vinyl into true value and benefits for all our customers and stakeholders alike. For more information visit: www.forbo-flooring.com

Open the catalog to page 1

Environmental Product Declaration FLOORING SYSTEMS Acoustic Vinyl Resilient Floor Covering According to ISO 14025 & EN 15804 This declaration is an environmental product declaration in accordance with ISO 14025 and EN15804 that describes the environmental characteristics of the aforementioned product. It promotes the development of sustainable products. This is a certified declaration and all relevant environmental information is disclosed. This EPD may not be comparable to other declarations if they do not comply with ISO 14025, EN 15804 and the reference PCR.

Open the catalog to page 2

Acoustic Vinyl Resilient Floor Covering Product Definition Product Classification and Description This declaration covers a broad range of designs and colors. Acoustic vinyl is a resilient floor covering complying with all the requirements of EN 651 / ISO 11638: Resilient floor coverings – Heterogeneous polyvinyl chloride flooring on foam - Specification. The key raw materials include glass fiber, binders (PVC and calcium carbonate), plasticizer and water-based inks. Acoustic vinyl is produced by Forbo Flooring and is sold worldwide. This declaration refers to Acoustic vinyl (sheet or...

Open the catalog to page 3

Environmental Product Declaration FLOORING SYSTEMS Acoustic Vinyl Resilient Floor Covering According to ISO 14025 & EN 15804 Acoustic vinyl is classified in accordance with EN 651 / ISO 11638 to be installed in the following use areas defined in EN-ISO 10874: The products considered in this EPD have the following technical specifications: o Meets or exceeds all technical requirements in EN 651 / ISO 11638 Resilient floor coverings - Heterogeneous polyvinyl chloride flooring on foam - Specification a Acoustic vinyl meets the requirements EN 13501-1 Reaction to fire o ISO 9001 Quality...

Open the catalog to page 4

Environmental Product Declaration (fodbo FLOORING SYSTEMS Acoustic Vinyl Resilient Floor Covering According to ISO 14025 & EN 15804 Delivery Status Table 1: Specification of delivered product Production of Main Materials PVC: Polyvinyl chloride is obtained by polymerization of the monomer vinyl chloride. Plasticizer: DOTP, a non-phthalate plasticiser, being the diester of terephthalic acid and the branched-chain 2-ethylhexanol. This colorless viscous liquid used for softening PVC plastics is known for chemical similarity to general purpose phthalates such as DEHP and DINP, but without...

Open the catalog to page 5

Environmental Product Declaration FLOORING SYSTEMS Acoustic Vinyl Resilient Floor Covering According to ISO 14025 & EN 15804 Inks : water-based inks Acoustic vinyl is produced in several stages starting with the impregnation of the glass fiber (consists of filling the glass fiber with a PVC paste) and the rotogravure printing (possibility to deposit different patterns and colors). The next stage is the wear layer gelation with a coating technology (a transparent wear layer on all products). Then the product is put back to deposit a coat of compact reinforcing PVC and a coat of PVC...

Open the catalog to page 6

Environmental Product Declaration FLOORING SYSTEMS Acoustic Vinyl Resilient Floor Covering According to ISO 14025 & EN 15804 Waste during the installation process may be recycled or landfilled. Packaging Cardboard tubes and packaging paper can be collected separately and should be used in a local recycling process. The service lifetime of a floor covering for a certain application on a floor is too widespread to give one common number. For this EPD model the reference service lifetime (RSL) is set to one year. This means that all impacts for the use phase are based on the cleaning and...

Open the catalog to page 7

Acoustic Vinyl Resilient Floor Covering Health Aspects During Usage Acoustic Vinyl is in compliance with: o AgBB requirements o French act Grenelle: A+ o Emission class M1 End of Life The deconstruction of installed Acoustic Vinyl from the floor is done mechanically and the electrical energy needed for this is estimated to be 0.03 kWh/sqm. This amount of energy is included in the calculations. For the End of Life stage 60% landfill and 40% incineration is taken into account, the average distance to the incineration plant or landfill per lorry is set to 200 km. Life Cycle Assessment A full...

Open the catalog to page 8

Acoustic Vinyl Resilient Floor Covering waste. Transport data on all considered inputs and output material are also considered. Allocations In the present study some allocations have been made. Detailed explanations can be found in the chapters below. Co-product allocation No co-product allocation occurs in the product system. Allocation of multi-input processes The Production and End of Life stage include incineration plants. In these processes different products are treated together within a process. The allocation procedures followed in these cases are based on a physical classification...

Open the catalog to page 9

Acoustic Vinyl Resilient Floor Covering revision of the used data sets took place within the last 10 years. System Boundaries Production Stage includes provision of all materials, products and energy, packaging processing and its transport, as well as waste processing up to the end-of waste state or disposal of final residues during the product stage. Transport and Installation Stage includes provision of all materials, products and energy, as well as waste processing up to the end-of-waste state or disposal of final residues during the construction stage. These information modules also...

Open the catalog to page 10All Forbo Flooring Systems catalogs and technical brochures

-

Colorex Life sciences

5 Pages

-

Colorex ELECTRONICS

5 Pages

-

Colorex automotive

5 Pages

-

Modul’up 19dB / Modul’up compact

16 Pages

-

showtime

25 Pages

-

TOPSHIELD2

4 Pages

-

TRANSPARENCY SUMMARY SMARAGD

2 Pages

-

TRANSPARENCY SUMMARY ETERNAL

2 Pages

-

EPD SMARAGD

42 Pages

-

EPD MARMOLEUM TILE 2.0 AND 2.5MM

51 Pages

-

EPD MARMOLEUM DECIBEL

44 Pages

-

EPD MARMOLEUM 2.0 AND 2.5MM

53 Pages

-

FORBO LIFE SCIENCES

5 Pages

-

FLOTEX BY TIBOR

24 Pages

-

SARLON ACOUSTIC VINYL BROCHURE

20 Pages

-

Furniture linoleum

13 Pages

-

TRUE TO NATURE allura magazine

31 Pages

-

Needlefelt

11 Pages

-

Sphera® homogeneous vinyl

16 Pages

-

THE NEXT GENERATION OF MARMOLEUM

37 Pages

-

MARMOLEUM MODULAR TEXTURA

2 Pages

-

MARMOLEUM AQUAJET

24 Pages

-

Step safety vinyl

24 Pages

-

Coral entrance flooring

15 Pages

-

Bulletin Board

11 Pages

-

MARMOLEUM SPORT

11 Pages

-

CHO brochure

9 Pages

-

Marine Brochure

8 Pages

-

Bus & Coach Brochure

20 Pages

-

Rail Brochure

15 Pages

-

Sarlon Modul'Up brochure

20 Pages

-

Allura LVT brochure

14 Pages

-

Marmoleum Textura Leaflet

1 Pages

-

Marmoleum Click

9 Pages

-

MARMOLEUM MODULAR

19 Pages

-

Flotex brochure

32 Pages

-

Marmoleum Meets Mendini

46 Pages

-

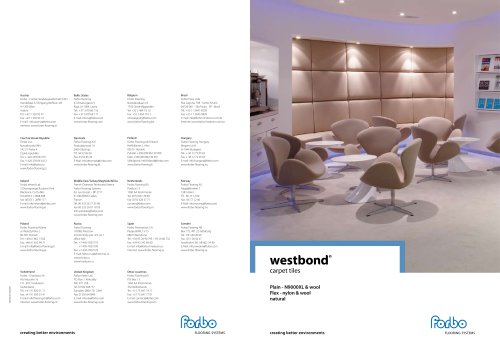

Westbond

8 Pages

-

Decorative Linoleum Flooring

24 Pages

-

Showtime®

40 Pages

-

COLOREX BROCHURE

26 Pages

-

FORBO MARMOLEUM MAGAZINE

37 Pages

-

ACOUSTIC

16 Pages

Archived catalogs

-

Needlefelt

20 Pages