Website:

DALIFORM GROUP srl

Website:

DALIFORM GROUP srl

Group: Daliform

Catalog excerpts

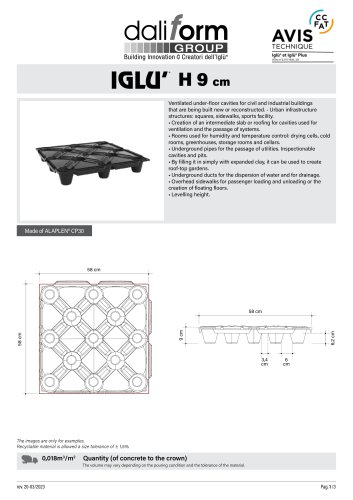

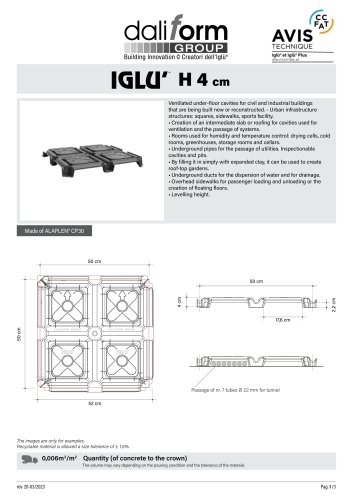

Disposable formwork for ventilated under-floor cavities dali/brm GROUP

Open the catalog to page 1

KEY: Water, collection tanks Cold rooms Utility passage SWITCHBOARD Telephone +39 0422 2083 Fax +39 0422 800234 FOREIGN COMMERCIAL SECRETARY OFFICE export@daliform.com TECHNICAL SECRETARY OFFICE tecnico@daliform.com

Open the catalog to page 2

Iglù® is a market leading product that was created and patented for the realisation of sanitary spaces, ventilated cavities, under-floor cavities, ventilated floors and roofs during the construction and restructuring of civil and industrial buildings. This result of an ingenious idea dating back to 1993 considerably improved building methods. The innovative capacity of Iglù® has received numerous successes and recognitions on a national and international level, quickly confirming it as a product of excellence in the building world. The modular, plastic Iglù® formworks, placed side by side...

Open the catalog to page 3

The problem for buildings: rising moisture The problem of rising moisture from the ground and its results on the integrity of the structures and the healthiness of the inner rooms has been well known since antique Rome. At those times, the under-floor cavities were created by raising the floor a few centimetres using amphoras or low walls. This created a cavity that was connected to the outside with ventilation inlets in order to guarantee ventilation (so-called ventilated wall cavity). This formed the basis for what is today commonly called a "sanitary space". The Roman technique has...

Open the catalog to page 4

The final solution: Iglù® A ventilated under-floor cavity created with Iglù® represents an effective, quick and economic solution that makes it possible to send humidity and dangerous Radon gas to the atmosphere, which is beneficial to our health. The air cavity formed by the Iglù® modules must be connected to the outside with simple pipes. This creates a natural air flow that crosses the cavity and eliminates moisture and Radon gas (if present). The results of some ventilation tests (carried out on our behalf by the University of Brno - Czech Republic - available on request) indicate that...

Open the catalog to page 5

Advantages • Possibility to implement, in a single solution, foundation beams and the slab with the help of the L-Plast and Beton Bridge accessories. • Reduction of manpower requirements by up to 80% in comparison to traditional systems. • Drastic reduction in the use of concrete and aggregates as the arch form permits maximum resistance with a minimum thickness. • Adaptable to non-standard spaces as the modules can be cut without underpinning. • Ease of positioning due to lightness and simple linking of the modules. • Simple adaptation to various perimeters. • Quick and immediate cutting...

Open the catalog to page 6

Graphic analysis of the behaviour of concrete structures The overload hypotheses indicated are normally those laid down by law; the actual load capacity is far superior. To know the exact values or sizing as shown in the project, contact the technical department. Pressure at pillar base Kg/cm2

Open the catalog to page 9

Method for creating under-floor cavities 4 1 Preparation of the natural ground. 2 Preparation of the lean concrete foundation, to be sized according to the loads and capacity of the ground. 3 Positioning the L-Plast panel around the foundation beams after positioning the necessary reinforcements. Positioning the linking male/female formworks, working from the left to the right, from the top down, making sure the arrow is facing upward. 5 Laying the welded mesh Ø 6 20x20 above the formworks. Casting the concrete starting from the centre of the arc, letting it go inside the legs of the...

Open the catalog to page 10

Fig. 1 - Dry positioning of the first formwork, the arrow is facing the foundation curb. Fig. 2 - Dry positioning sequence of the modules by row. Position the first element to the upper left with respect to the work surface, making sure that the arrow is pointing up (Fig. 1). Unite the elements in sequence, by horizontal row, proceeding from the left towards the right and from the top downwards (following the direction normally used for writing), as shown graphically on the crown of each unit (Fig. 2). 3 To unite the units in sequence, be careful to perfectly link the “male-female” hooking...

Open the catalog to page 11

Application example: cold rooms Cold rooms are used everywhere in the food industry for food storage. They are divided into low temperature (-4°C -30°C) and medium temperature (0°C +4°C) rooms. A common problem associated with low temperature cold rooms is the possibility that the cold is transmitted through the structure, reaching the ground and bringing it to a temperature below zero. The water freezes and, increasing in volume, can lift the floor of the cold room, breaking it. To avoid this problem, in addition to an insulating layer it is also common to lift the floor off the ground and...

Open the catalog to page 12

Application example: anti-root cavities Urban greenery has become an indispensable aspect for improving the quality of life and making cities more vibrant and colourful. The idea to create a city garden was developed almost 200 years ago, and in Italy the trend is to create parks, urban woods and “green belts” Often, however, the green is simply inserted to the side of roads, on . sidewalks or bicycle paths. Maintenance work must be carried out regularly as the tree roots lift up the pavement until breaking through and then going back underground, following a horizontal path. The Iglù®...

Open the catalog to page 13

Acoustic insulation Law 447/95 foresees the protection against noise transmission in buildings, which can be done in particular through acoustic floor insulation. This can be implemented by creating horizontal structures of a suitable mass, placing layers of material between the floor and the screed that dampens the vibrations due to impact noise. Depending on the building's use, the law specifies the different phono insulation parameters. With the help of Iglù® H 4-8-12 cm, which is placed between the screed and the slab structure, a noise control mechanism is implemented that makes it...

Open the catalog to page 14All DALIFORM GROUP srl catalogs and technical brochures

-

H09-iglu-en

3 Pages

-

H08-iglu-en

3 Pages

-

H06-iglu-en

3 Pages

-

H05-iglu-en

3 Pages

-

H04-iglu-en

3 Pages

-

U BOOT-SILENCE

8 Pages

-

EOLO

9 Pages

-

GREENPARK_EN

8 Pages

-

V-Green_EN

4 Pages

-

IGLU-Smart-EN

4 Pages

-

COFFRARGILE

12 Pages

-

IGLU'® VENTILATED ROOF

8 Pages

-

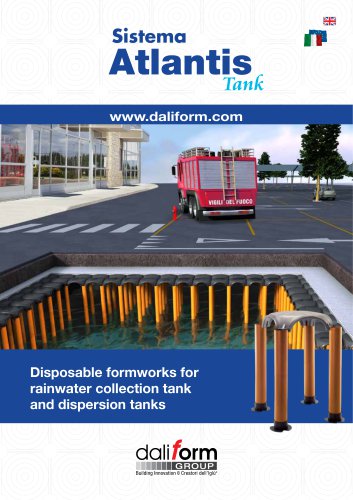

ATLANTIS

16 Pages

-

ISO IGLU'

8 Pages

-

ATLANTIS TANK

20 Pages

-

PARATOPRATICO®

16 Pages

-

E.C.O. by PRATOPRATICO®

8 Pages

-

V-GREEN®

4 Pages

-

ERBY SALVAPRATO

4 Pages

-

Cassaforma Muro

10 Pages

-

ATLANTIS SWIMMING POOL

12 Pages

-

Company Profile

12 Pages

-

EASY RIDE

4 Pages

-

EASY PARK®

8 Pages

-

EOLO

9 Pages

-

U-BOOT SILENCE

8 Pages

-

U-BAHN® BETON

10 Pages

-

IGLU'® GREEN ROOF

12 Pages

-

FIT SLAB

10 Pages

-

U-BOOT® BETON

21 Pages

-

Conrete accessories

20 Pages