Website:

ADAMATIC

Website:

ADAMATIC

Group: AGA Group

Catalog excerpts

TFF-IV High Volume Donut Fryer Simply the BEST (and LONGEST) donut fryer in the market today. ►► 19, 23, 28, 32 and 40 feet fryer lengths available ►► Low shortening volume for high turnover rates ►► Continuous shortening filtration using advanced Stein MX Filter System (optional) ►► Continuous sediment removal system (optional) ►► Designed for use with Trans Fat Free donut fry oil ►► Incorporates THERMoFIN® heat exchanger technologies ABOUT JBT FoodTech (known formerly as Stein) has held the leadership role for many years in developing frying technologies for food processing fryers. For 90 years Belshaw has specialized in the design and manufacture of donut production equipment in every size range. Belshaw soon began exporting donut fryers and equipment worldwide, then manufactured its first wholesale donut systems and followed these up with high volume industrial systems from the 1980’s onward. Today, users of Belshaw equipment include retail bakeries, wholesale bakeries, industrial plants and supermarkets in virtually every part of the world. In 1991, JBT FoodTech undertook a fryer design with revolutionary vertical fins and fluid heat transfer to the cooking oil through a heat exchanger. It became apparent that this method had advantages over traditional Direct Heat/Direct Fired gas systems. This resulted in the development of the THERMoFIN® Fryer, with an overall performance result that exceeded any tubular design fryer in the market place. The newest generation of THERMoFIN® Fryer designs include intelligent oil management through more gentle and efficient heat transfer, as well as continuous filtration of the cooking oil with efficient sediment removal, greatly extending oil life, particularly for trans fat free oils. This patented design is currently the market leader in frying technologies for continuous frying applications – with over 500 fryers and 35 million frying hours contributing to its success. Belshaw donut systems simplify high volume donut production and synchronize the Proofing, Cake Donut Depositing, and Frying functions. Belshaw’s long experience in donut production ensures that a Belshaw donut system often continues working for decades after its initial installation. The partnership between Belshaw and JBT FoodTech enables industrial donut producers to take advantage of the combination of Belshaw’s donut production expertise and JBT FoodTech’s clean frying technologies. BELSHAW ADAMATIC BAKERY GROUP 814 44TH ST NW, SUITE 103, AUBURN WA 98001 INFO@BELSHAW.COM WWW.BELSHAW.COM

Open the catalog to page 1

More facts about the TFF-IV High Volume Donut Fryer The Belshaw–JBT FoodTech TFF-IV High Volume Donut Fryer has numerous features that benefit donut production: Gentle heat to preserve shortening • The TFF-IV’s THERMoFIN® dual heat exchangers present a very large fin surface area to enable steady heat transfer without scorching oil or shortening, and without ‘hot spots’ • Temperature differentials are typically as low as 100°F between heat exchanger surface and frying temperature • Temperature deviations in the fryer are designed to be as low as 2°F side-to-side or end-to-end Easy removal...

Open the catalog to page 2All ADAMATIC catalogs and technical brochures

-

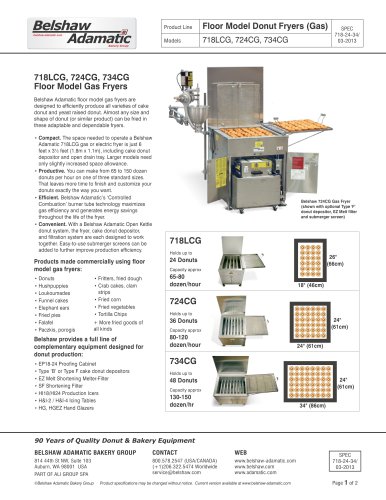

Belshaw 718L-724-734

2 Pages

-

Harmony Modular Deck

8 Pages

-

Dough Dividers

8 Pages

-

Moulders

8 Pages

-

BL Bowl Lift

2 Pages

-

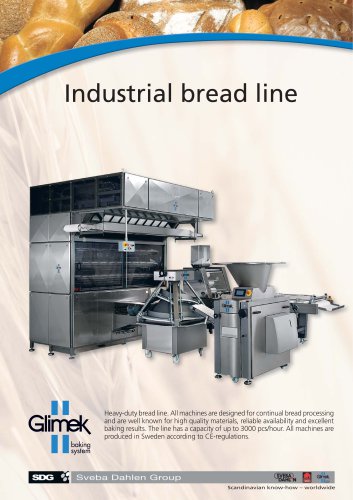

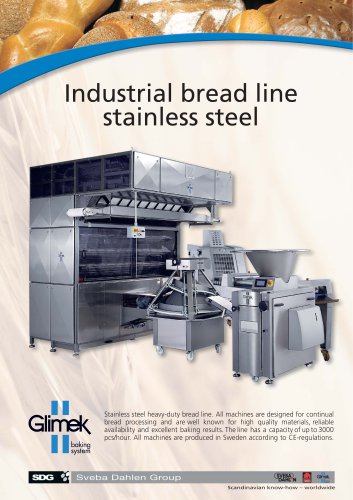

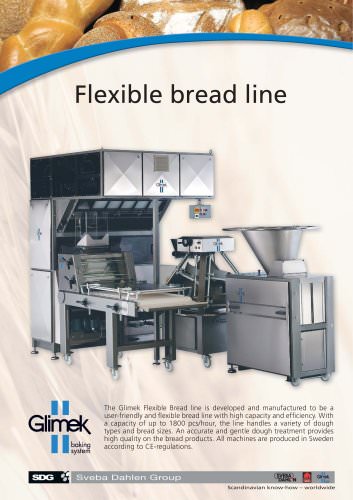

Bread Lines

12 Pages

-

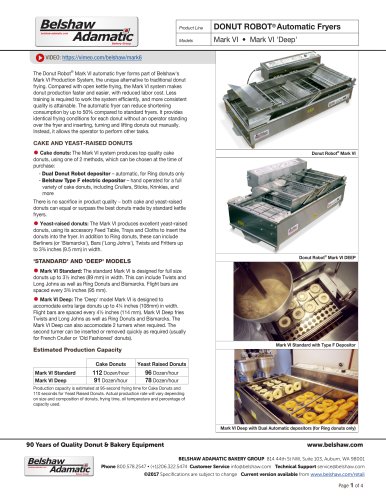

Mark VI ‘Deep’ System

2 Pages

-

TYPE K PANCAKE DISPENSER

2 Pages

-

Hushpuppy Depositor

2 Pages

-

Type F-YRD

2 Pages

-

Type F

2 Pages

-

PRF-2022

2 Pages

-

PRF-2021

2 Pages

-

OVEN-2010

2 Pages

-

DX Oven

2 Pages

-

OVEN 2020

4 Pages

-

Rack Loader

2 Pages

-

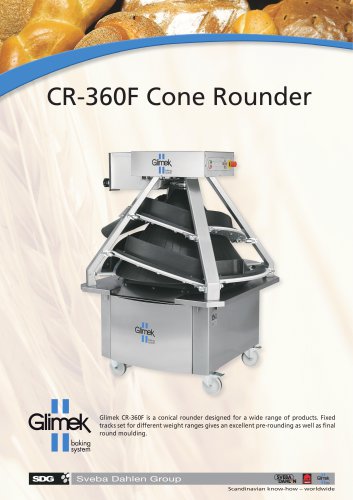

Glimek CR-360 Cone Rounder

2 Pages

-

Adamatic VDR Divider Rounder

2 Pages

-

Adamatic NDR Divider Rounder

2 Pages

-

Glimek Artisan Bread Line

2 Pages

-

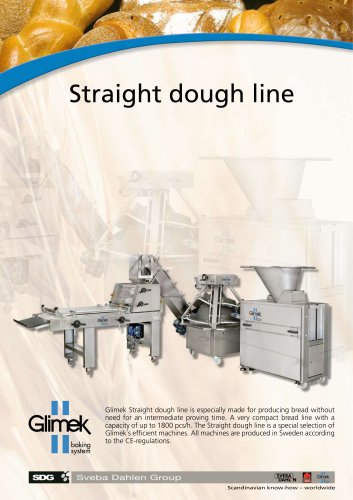

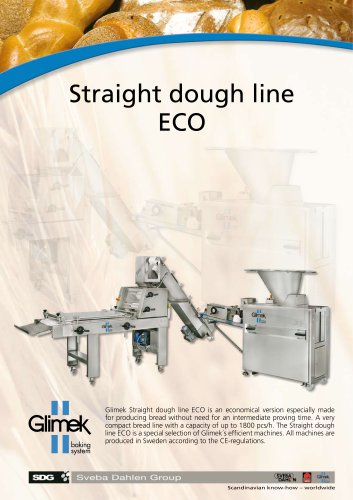

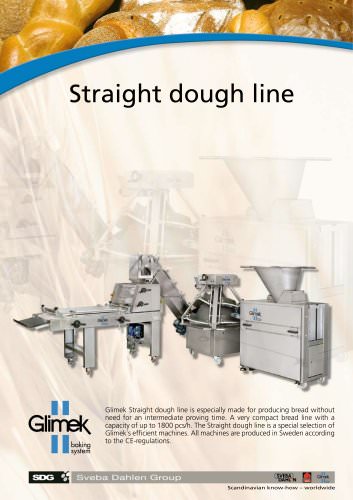

Glimek Straight Dough Line

2 Pages

-

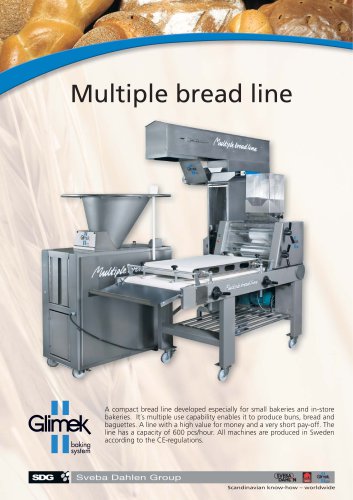

Glimek Multiple Bread Line

2 Pages

-

Glimek Eco-line

2 Pages

-

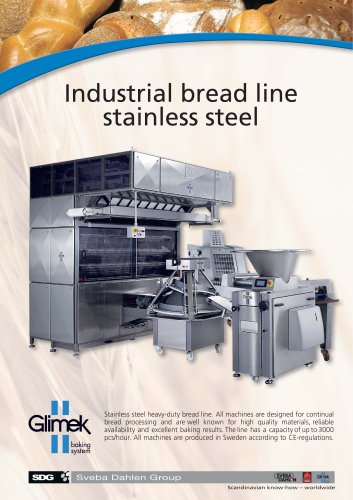

Glimek Flexible Bread Line

2 Pages

-

Glimek SD-300 Dough Divider

2 Pages

-

Glimek CR-360F Cone Rounder

2 Pages

-

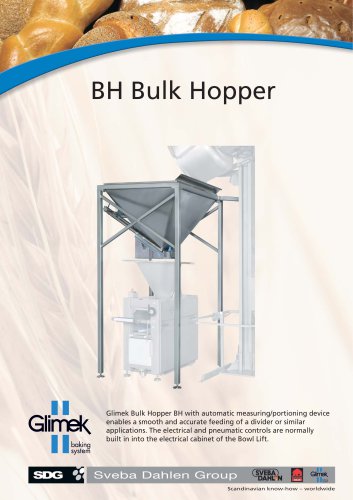

Glimek BH Bulk Hopper

2 Pages

-

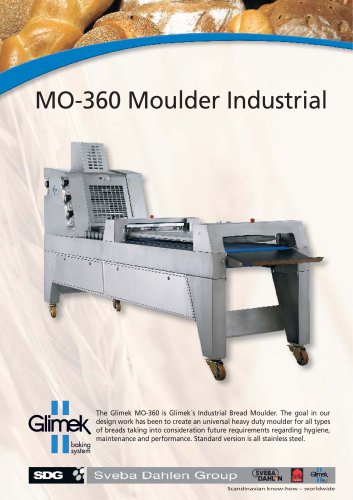

Glimek MO-360 Moulder

2 Pages

-

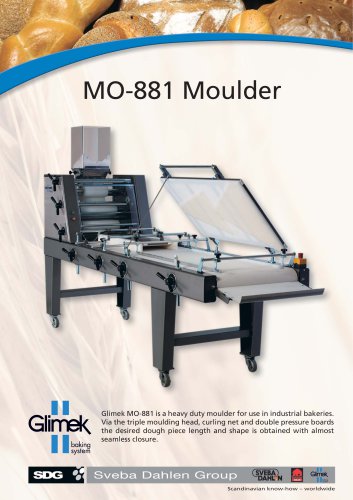

Glimek MO-881 Moulder

2 Pages

-

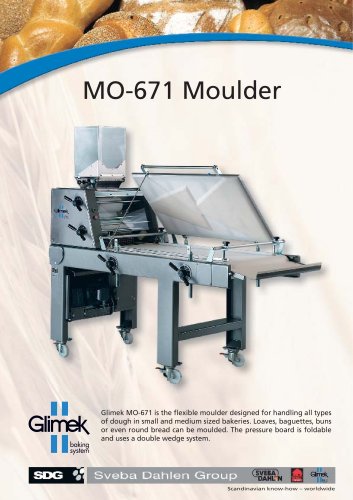

Glimek MO-671 Moulder

2 Pages

-

Glimek SD-600 Dough Divider

2 Pages

-

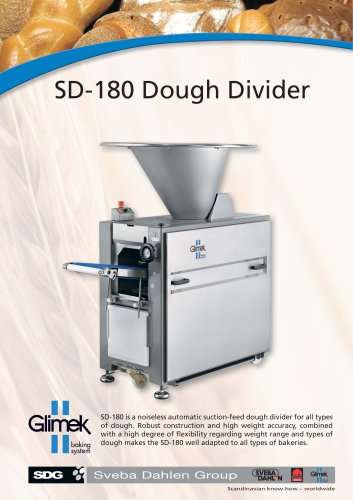

Glimek SD-180 Dough Divider

2 Pages

-

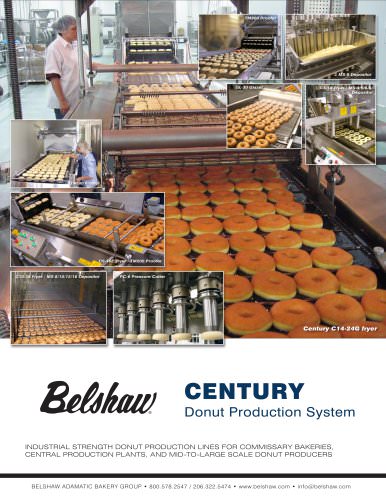

Century System Brochure

6 Pages

-

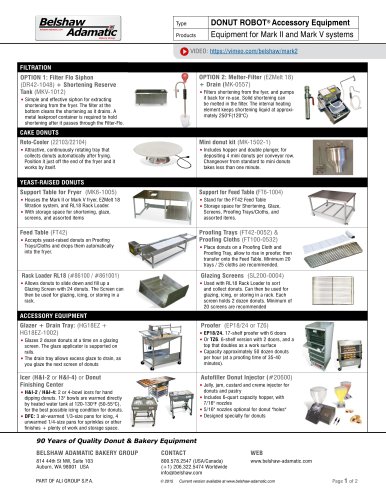

Donut Robot® Mark VI

4 Pages

-

Donut Robot® Mark V

4 Pages

-

Donut Robot® Mark II (Gas)

2 Pages

-

Type K Donut Depositor

9 Pages

-

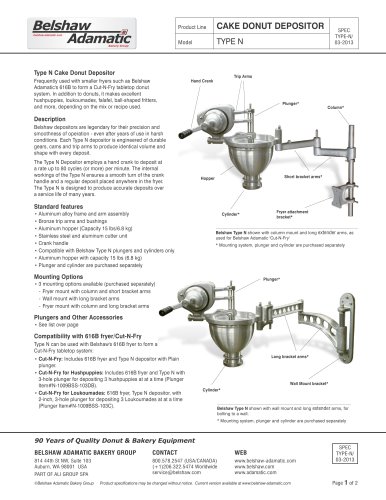

Type N Cake Donut Depositor

2 Pages

-

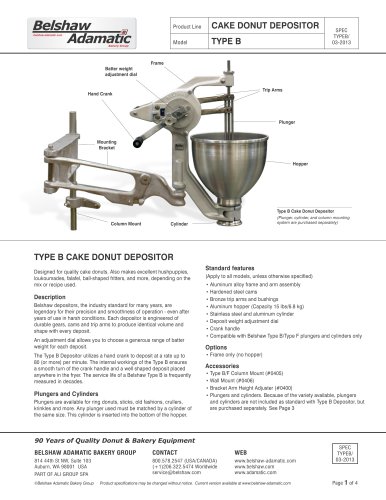

Type B Cake Donut Depositor

4 Pages

-

618L Donut Fryer (Electric)

2 Pages

-

616B Donut Fryer

2 Pages

-

VDR Divider Rounder

2 Pages

-

NDR Divider Rounder

2 Pages

-

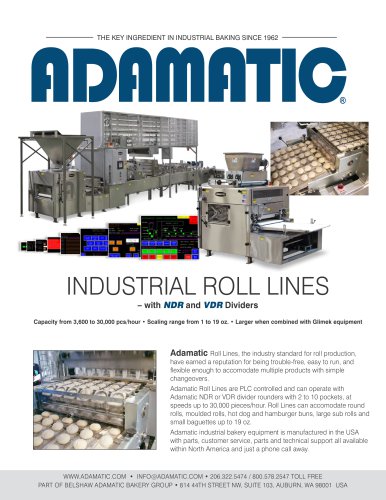

INDUSTRIAL ROLL LINES

3 Pages

-

The BX Eco-touch

4 Pages

-

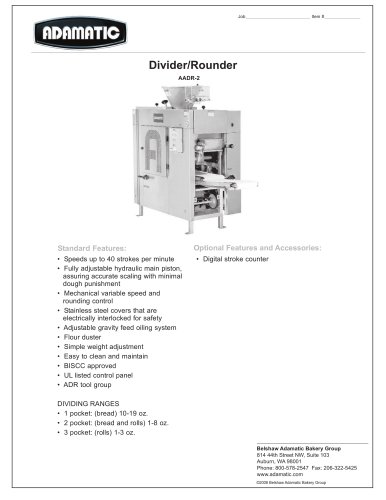

ADR2 Divider Rounder

1 Pages

-

SD-300

2 Pages

-

MO-671

2 Pages

-

CR-360

2 Pages

-

Straight dough line

2 Pages

-

Multiple bread line

2 Pages

-

Flexible bread line

2 Pages

-

Eco bread line

2 Pages

-

Artisan bread line

2 Pages

Archived catalogs

-

AMDO-2W

2 Pages

-

BX3-E - BX4-E

6 Pages

-

AADR-2

2 Pages

-

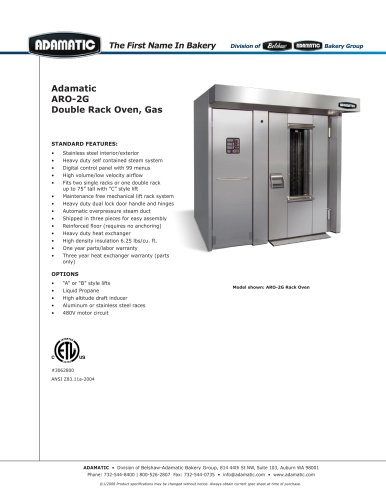

ARO-2G

2 Pages

-

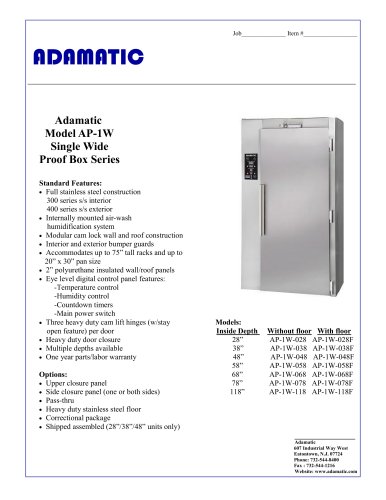

AP-1W

2 Pages

-

AMRO-G Series

2 Pages

-

USR01

2 Pages

-

AMRO-E series

2 Pages

-

Adamatic AP-2W

2 Pages

-

ADAMATIC Catalog

59 Pages

-

Supermarket/Retail brochure

4 Pages

-

Foodservice brochure

4 Pages

-

Wholesale brochure

4 Pages